You walk into a hardware store, see regular window glass, and think it’s perfect for your greenhouse project. The price seems right, the transparency looks good, but you’re making a costly mistake that could destroy your crops and waste thousands of dollars.

Greenhouse glass isn’t ordinary household glass. Professional greenhouses use specialized tempered, insulated, and diffuse glass systems designed for optimal plant growth, safety, and energy efficiency – each serving critical functions that regular glass simply cannot provide.

After 29 years in the greenhouse industry, I’ve seen countless growers make this expensive assumption. The glass you choose determines whether your greenhouse becomes a thriving agricultural investment or an energy-draining liability.

Why Isn’t Regular Household Glass Suitable for Greenhouses?

Your home windows face completely different challenges than greenhouse glass. Regular glass breaks under thermal stress, wastes energy, and creates dangerous conditions that can harm both plants and people.

Regular household glass lacks the structural integrity, thermal properties, and safety features required for greenhouse environments. It cannot withstand temperature fluctuations, wind loads, or provide the specialized light transmission needed for optimal plant growth.

The Hidden Dangers of Using Regular Glass

Regular window glass operates in stable indoor environments with minimal temperature changes. Your greenhouse experiences extreme conditions that would shatter ordinary glass within months. I remember visiting a customer in Thailand who tried to save money using regular glass for his orchid greenhouse. Within six months, thermal expansion cracked 40% of his panels during the rainy season.

Temperature swings in greenhouses can exceed 30°C between day and night. Regular glass expands and contracts at different rates than the frame, creating stress fractures. These cracks start small but spread rapidly, eventually causing complete panel failure.

Wind loads present another critical challenge. Greenhouses experience higher wind pressure than buildings due to their shape and height. Regular glass cannot handle these structural demands. The thickness standards for household glass (typically 3mm) are insufficient for greenhouse applications where 4-5mm minimum thickness is required.

| Property | Regular Glass | Greenhouse Glass |

|---|---|---|

| Thickness | 3mm standard | 4-5mm minimum |

| Wind Load Capacity | Low | High |

| Thermal Shock Resistance | Poor | Excellent |

| Safety Rating | None | Tempered/Safety |

| Light Transmission | Basic | Optimized |

Light transmission quality differs significantly between regular and greenhouse glass. Household glass often contains iron impurities that create a greenish tint, reducing photosynthetically active radiation (PAR) that plants need. This seemingly minor difference can reduce crop yields by 10-15%.

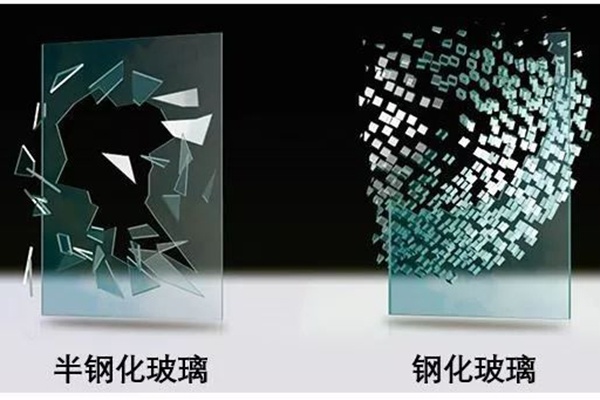

Safety and Strength Advantages of Tempered Glass in Greenhouse Applications?

Tempered glass transforms ordinary silica into a safety powerhouse through controlled heating and rapid cooling. This process creates internal stresses that make the glass four to five times stronger than regular glass while ensuring safe breakage patterns.

Tempered glass provides essential safety protection in greenhouse environments by shattering into small, rounded pieces instead of dangerous shards. Its superior strength handles thermal stress, wind loads, and impact resistance required for agricultural applications.

The Tempering Process and Its Benefits

The tempering process begins by heating glass to approximately 650°C, then rapidly cooling it with jets of cold air. This creates compressive stress on the surface while maintaining tensile stress in the core. The result is glass that can withstand thermal shock up to 250°C – perfect for greenhouse environments.

I witnessed the importance of this safety feature during a hailstorm in our test facility in Chengdu. Regular glass panels would have created thousands of razor-sharp fragments, but our tempered panels either remained intact or broke into harmless pebble-sized pieces. This protection is crucial when workers are inside the greenhouse during severe weather.

Strength advantages extend beyond safety. Tempered glass can handle snow loads up to 150 kg/m², while regular glass fails at 50 kg/m². This difference becomes critical in regions with heavy snowfall or when supporting equipment like shade systems or heating pipes.

The thermal expansion coefficient of tempered glass remains stable across temperature ranges. Regular glass develops micro-fractures when subjected to rapid temperature changes, but tempered glass maintains structural integrity. This reliability ensures your greenhouse investment lasts decades rather than requiring frequent panel replacements.

| Strength Factor | Regular Glass | Tempered Glass |

|---|---|---|

| Impact Resistance | 1x baseline | 4-5x stronger |

| Thermal Shock Tolerance | 40°C | 250°C |

| Snow Load Capacity | 50 kg/m² | 150 kg/m² |

| Breakage Pattern | Sharp shards | Small rounded pieces |

| Service Life | 5-8 years | 20+ years |

Quality tempered glass for greenhouses must meet specific standards. We ensure our glass passes the ball drop test (dropping a 2.26kg steel ball from 3 meters) and thermal shock testing. These quality controls guarantee performance under real-world greenhouse conditions.

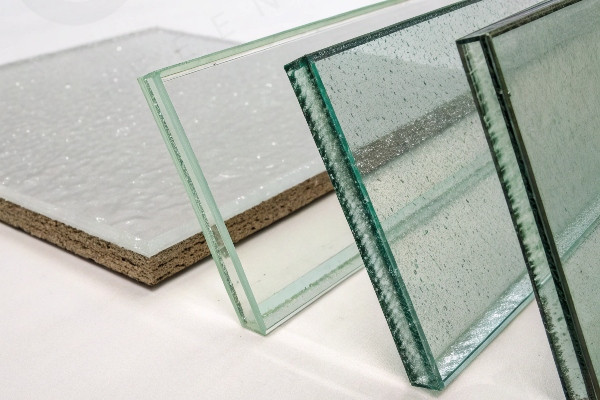

The Insulation Principle and Effectiveness of Insulated Glass (Double Glazing)?

Insulated glass systems create thermal barriers using trapped air or gas between two glass panes. This simple concept revolutionizes greenhouse energy efficiency by reducing heat loss during cold periods and minimizing heat gain during hot weather.

Insulated glass reduces heat transfer by up to 50% compared to single-pane glass through the thermal barrier created by the air gap between panes. This dramatically improves greenhouse climate control while reducing heating and cooling costs.

Understanding Heat Transfer in Greenhouse Glass

Heat moves through glass in three ways: conduction, convection, and radiation. Single-pane glass allows direct conduction, making temperature control expensive and difficult. Insulated glass interrupts this process by creating a dead air space that acts as insulation.

The optimal air gap for greenhouse applications ranges from 12-16mm. Smaller gaps allow convection currents, while larger gaps create their own convection problems. Our testing shows 14mm spacing provides the best balance of insulation and structural integrity for greenhouse environments.

During winter trials at our facility, single-pane greenhouses required 40% more heating energy than identical structures with insulated glass. This translates to significant cost savings over the greenhouse’s lifetime. For a 1000m² greenhouse in Central Asia, the annual energy savings can exceed $3,000.

Gas fills improve insulation performance further. Argon gas, being denser than air, reduces convection within the air gap. However, for most greenhouse applications, the cost increase doesn’t justify the marginal improvement. Air-filled units provide excellent performance at reasonable cost.

| Performance Metric | Single Pane | Insulated Glass | Improvement |

|---|---|---|---|

| U-Value (W/m²K) | 5.8 | 2.8 | 52% better |

| Heating Cost Reduction | Baseline | 35-40% less | Significant |

| Condensation Control | Poor | Excellent | Major benefit |

| Temperature Stability | Variable | Stable | Improved |

Condensation control represents another major advantage. The inner pane of insulated glass stays warmer, preventing condensation that can drip on plants and create disease problems. This benefit alone justifies the investment for high-value crops like orchids or tomatoes.

The spacer material between glass panes affects performance. We use warm-edge spacers made from thermally broken materials rather than aluminum, which conducts heat. This detail prevents thermal bridging and maintains the insulation barrier’s effectiveness.

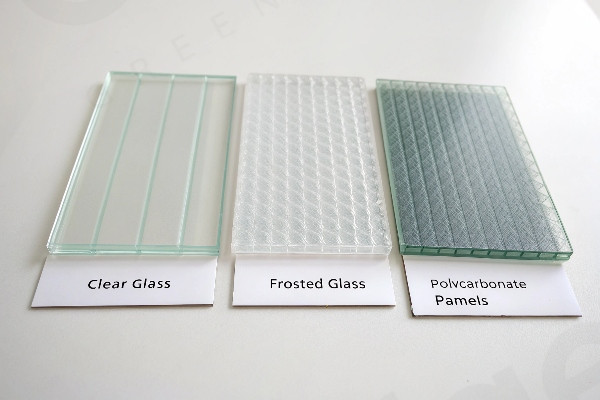

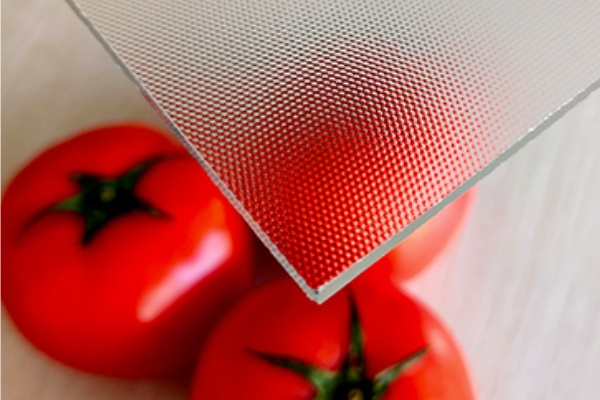

How Does Diffuse Glass Improve the Light Environment Inside a Greenhouse?

Diffuse glass scatters incoming sunlight to eliminate harsh shadows and hot spots while maintaining high light transmission. This creates uniform illumination that promotes even plant growth and reduces stress from direct solar radiation.

Diffuse glass improves plant growth by scattering direct sunlight into soft, even illumination throughout the greenhouse. This eliminates shadows, reduces leaf burning, and increases photosynthesis efficiency by up to 15% compared to clear glass.

The Science Behind Light Diffusion

Clear glass creates distinct shadows and bright spots that stress plants and create uneven growth patterns. Diffuse glass contains microscopic surface structures that bend light rays in multiple directions without reducing overall transmission. This process, called Rayleigh scattering, mimics natural cloud cover.

The key measurement for diffuse glass is the haze factor – the percentage of transmitted light that gets scattered. For greenhouse applications, we recommend haze factors between 40-70%. Lower values don’t provide sufficient diffusion, while higher values can reduce light transmission below optimal levels.

I observed this benefit dramatically during trials with rose growers in the Netherlands. Greenhouses with clear glass showed 30% variation in flower quality between sunny and shaded areas. The same varieties under diffuse glass produced uniform, premium-quality blooms throughout the structure.

Light penetration improves significantly with diffuse glass. Direct sunlight often reflects off upper leaves, preventing light from reaching lower plant levels. Diffused light bounces between leaves, improving photosynthesis in the entire plant canopy. This effect increases yields in crops like tomatoes and cucumbers by 10-15%.

Temperature benefits complement the light advantages. Diffuse glass reduces hot spots that can damage sensitive plants while maintaining necessary light levels. Surface temperatures under clear glass can exceed 45°C, while diffuse glass keeps temperatures below 35°C – within the optimal range for most crops.

| Light Quality Factor | Clear Glass | Diffuse Glass | Improvement |

|---|---|---|---|

| Light Uniformity | 60% variation | 15% variation | 75% better |

| Canopy Penetration | Poor | Excellent | Significant |

| Hot Spot Temperature | 45°C+ | <35°C | Safer |

| Yield Increase | Baseline | 10-15% higher | Measurable |

The manufacturing process for diffuse glass involves either acid etching or applying special coatings during production. Acid-etched surfaces provide permanent diffusion that won’t degrade over time, while coated versions offer precise control over diffusion levels. We prefer acid-etched surfaces for greenhouse applications due to their durability and self-cleaning properties.

Choosing the Right Glass System for Your Greenhouse

Different greenhouse applications require different glass solutions. Flower production benefits most from diffuse glass on the roof to provide soft, even lighting. Vegetable production often uses clear glass on vertical surfaces for maximum light transmission during winter months.

Climate considerations affect glass selection significantly. Hot climates benefit from diffuse glass to reduce cooling costs, while cold climates need insulated glass to minimize heating expenses. Many modern greenhouses combine both technologies, using diffuse insulated glass for optimal performance.

For customers growing high-value crops like orchids, we recommend laminated insulated glass on vertical surfaces for security and insulation, with diffuse tempered glass on the roof for optimal light conditions. This combination provides the perfect environment for premium flower production.

Maintenance requirements vary between glass types. Easy-clean glass coatings help in dusty environments, while reflective glass might be necessary for specific research applications. The key is matching glass properties to your specific growing requirements and local conditions.

Conclusion

Choosing the right greenhouse glass determines your project’s success. Tempered, insulated, and diffuse glass each serve critical functions that regular glass cannot provide for optimal plant growth and energy efficiency.