Selecting the wrong greenhouse glass can destroy your entire harvest and waste thousands in energy costs. Your plants need precise light and temperature control to survive.

Modern greenhouse glass systems combine 90%+ light transmission with superior insulation and 25+ year durability. The right glass choice maximizes plant growth while minimizing operational costs through advanced optical and thermal technologies.

In my 28 years of greenhouse construction experience, I have seen how glass technology evolved from simple single-pane solutions to sophisticated multi-layer systems. The early days of Chinese greenhouse development relied heavily on basic 4-5mm tempered glass that provided adequate protection but limited performance. Today’s cultivation requirements demand much more sophisticated approaches that balance multiple performance factors simultaneously.

The Impact of Light on Plant Growth and the Importance of Glass Light Transmittance?

Poor light transmission silently kills your crops before you notice the damage. Every percentage point of lost light directly reduces photosynthesis and crop yields.

Glass light transmittance determines photosynthetic efficiency and plant health. High-quality horticultural glass achieves 90-95% transmission while filtering harmful UV radiation, creating optimal growing conditions for maximum yield potential.

Understanding light transmission requires examining how different wavelengths affect plant development processes. Red light wavelengths between 660-700nm drive photosynthesis and promote flowering in many crops. Blue light wavelengths around 400-500nm encourage compact growth and strong stem development. Green light penetrates deeper into plant canopies than red or blue light, reaching lower leaves that contribute to overall plant energy production.

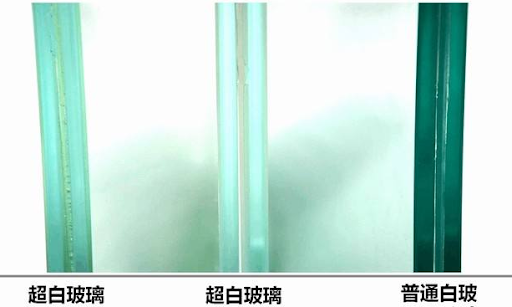

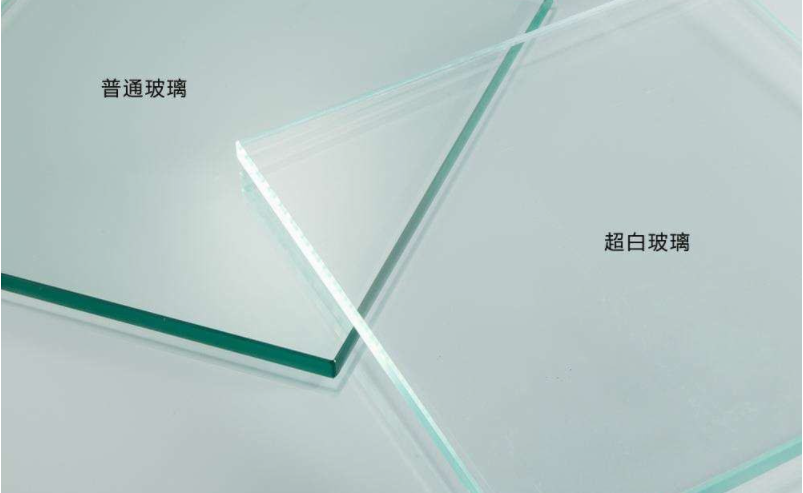

Standard float glass contains iron oxide impurities that absorb specific wavelengths important for plant growth. These impurities give glass a greenish tint and reduce transmission in the red spectrum where plants need maximum energy. Ultra-clear glass removes most iron content, improving transmission across all wavelengths critical for photosynthesis. The improvement may seem small in percentage terms but translates to measurable yield increases in commercial production.

I worked with a cucumber grower in southern Spain who complained about inconsistent fruit development despite using advanced climate control systems. His greenhouse used standard float glass achieving only 86% light transmission. We analyzed his growing environment and discovered that reduced light levels were limiting photosynthesis during peak production periods. After replacing the glazing with ultra-clear horticultural glass achieving 93% transmission, cucumber yields increased by 18% and fruit quality improved significantly.

Surface treatments on glass can further enhance or reduce light transmission depending on their purpose. Anti-reflective coatings reduce surface reflection losses that normally waste 4% of available light from each glass surface. In double-glazed systems, these reflection losses can total 16% of incident light. Anti-reflective treatments recover most of this lost light, effectively increasing available energy for photosynthesis.

Light quality affects different growth stages in varying ways. Seedlings require balanced light spectrums to develop strong root systems and compact growth habits. Vegetative growth benefits from higher blue light ratios that promote leaf development and stem strength. Flowering and fruiting stages need increased red light to trigger reproductive processes and fruit development. Glass selection should consider the primary growth stages occurring in the greenhouse.

Seasonal light variations require different glass strategies in many climates. Winter months with limited natural light benefit from maximum transmission glass to capture every available photon. Summer months with intense sunlight may benefit from slight transmission reduction to prevent heat stress while maintaining adequate photosynthetic energy. Some operations use seasonal glass replacement or adjustable systems to optimize performance year-round.

The angle of incident light affects transmission efficiency throughout the day. Glass performs optimally when light strikes perpendicular to the surface. As the sun angle changes, transmission decreases due to increased reflection and absorption. Greenhouse orientation and roof angles can optimize light capture during critical growing periods. Anti-reflective coatings help maintain transmission efficiency across a wider range of incident angles.

| Light Factor | Standard Glass | Horticultural Glass | Growth Impact | Economic Value |

|---|---|---|---|---|

| Total Transmission | 86-88% | 92-95% | Higher yields | +15-20% revenue |

| Red Light (660nm) | 82% | 94% | Better flowering | Improved quality |

| Blue Light (450nm) | 88% | 95% | Stronger plants | Reduced losses |

| UV Filtering | Limited | Controlled | Less stress | Healthier crops |

Choosing Haze Value for Greenhouse Glass: Adapting to Different Light Intensity Regions?

Direct sunlight creates devastating hot spots and deep shadows that waste light energy and stress your plants. Haze control transforms harsh light into productive illumination.

Optimal haze values range from 30-70% depending on regional light intensity and crop requirements. Higher haze reduces shadows and heat stress in bright climates while lower haze maximizes light capture in dim conditions.

Regional light intensity varies dramatically across different latitudes and climate zones. Equatorial regions receive intense direct sunlight year-round that can damage sensitive crops without proper diffusion. Temperate zones experience seasonal variations that require different approaches for summer and winter growing. Northern regions with limited winter sunlight need maximum light capture while still providing some diffusion benefits during brighter periods.

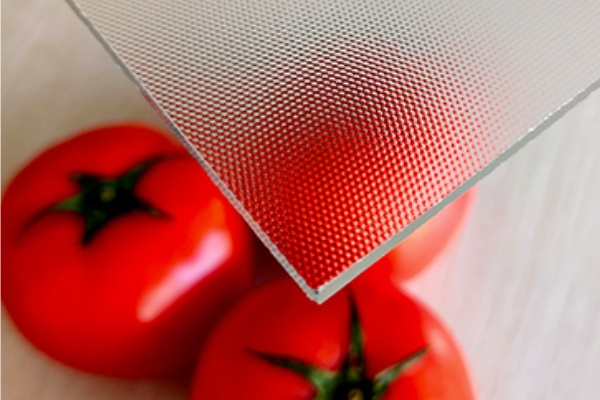

The science behind light diffusion involves scattering direct light rays into multiple directions, creating even illumination throughout the greenhouse. Microscopic surface textures or internal structures in the glass break up focused light beams and distribute energy more uniformly. This scattered light penetrates deeper into plant canopies and eliminates the sharp shadows that prevent lower leaves from contributing to photosynthesis.

I remember working with a tomato producer in Thailand who struggled with fruit quality variations across his greenhouse. Plants in direct sun paths produced small, heat-stressed fruit while those in shadowed areas showed poor development and delayed ripening. The extreme contrast created management challenges and reduced overall productivity. We installed structured diffuse glass with 65% haze value that scattered the intense tropical sunlight into gentle, even illumination. Fruit quality became uniform throughout the greenhouse, and yields increased by 22% due to improved light utilization efficiency.

Different crops respond differently to light diffusion based on their natural growing habits and canopy structures. Leafy greens like lettuce and spinach benefit significantly from high diffusion that allows light to penetrate dense leaf layers. These crops can utilize haze values up to 70% while maintaining adequate photosynthetic rates. Fruiting crops like tomatoes and peppers need some direct light components for proper fruit development but still benefit from shadow reduction through moderate diffusion levels around 40-50%.

Manufacturing methods for diffuse glass create different optical characteristics and durability properties. Acid-etched glass uses chemical processes to create microscopic surface roughness that scatters light effectively but may be more susceptible to dirt accumulation. Structured glass incorporates physical patterns during manufacturing that provide consistent diffusion properties and easier cleaning. Internal diffusion systems embed microscopic particles within the glass matrix for permanent diffusion that cannot be damaged by weathering or cleaning.

Climate considerations extend beyond simple light intensity to include factors like humidity, temperature extremes, and seasonal variations. Tropical climates with high humidity may require different diffusion strategies than dry desert regions with similar light intensities. Coastal areas with frequent fog or cloud cover need different approaches than inland areas with consistent sunshine. Professional greenhouse designers analyze local weather patterns over multiple years to select optimal haze values.

Maintenance requirements vary between different diffusion technologies and regional conditions. Smooth diffuse surfaces clean more easily than heavily textured ones, reducing maintenance costs in dusty environments. Some diffusion coatings may degrade over time in harsh UV conditions, requiring periodic replacement or restoration. Internal diffusion systems provide permanent performance but cannot be repaired if damaged. These factors influence long-term operating costs and system selection.

| Climate Zone | Recommended Haze | Primary Benefits | Typical Crops | Annual Light Hours |

|---|---|---|---|---|

| Tropical | 60-70% | Heat stress reduction | Orchids, leafy greens | 3000-3500 |

| Mediterranean | 40-60% | Balanced performance | Tomatoes, peppers | 2500-3000 |

| Temperate | 30-50% | Shadow reduction | Mixed vegetables | 2000-2500 |

| Northern | 20-40% | Light maximization | All crops | 1500-2000 |

| Desert | 70%+ | Extreme sun protection | Sensitive flowers | 3500+ |

The Perfect Combination of Aluminum Alloy Frames and Glass: Ensuring Greenhouse Stability and Durability?

Weak structural systems cause catastrophic glass failures that destroy crops and create safety hazards. Your frame choice determines whether your greenhouse survives severe weather events.

Aluminum alloy frames provide optimal strength-to-weight ratios while resisting corrosion in humid greenhouse environments. Proper engineering ensures 25+ year structural life with minimal maintenance requirements compared to steel alternatives.

Structural engineering for greenhouse frames involves complex calculations that consider multiple load types simultaneously. Dead loads from the frame and glazing create constant downward forces that must be transferred to foundations. Live loads from maintenance activities and equipment installations add variable forces throughout the structure. Wind loads create both positive and negative pressures that can lift or push the structure. Snow loads in cold climates add significant seasonal stresses that must be accommodated.

Material selection affects both immediate performance and long-term durability in greenhouse environments. Steel frames offer high strength and lower initial costs but require constant maintenance to prevent corrosion in humid conditions. Galvanized steel provides better corrosion resistance but adds weight and cost. Stainless steel offers excellent durability but costs significantly more than alternatives. Aluminum alloy provides the best balance of strength, weight, and corrosion resistance for most greenhouse applications.

I worked on a project in coastal Vietnam where the customer initially chose galvanized steel framing to minimize construction costs. The humid, salt-laden environment proved extremely corrosive, and within four years, rust had compromised several structural connections. Two glass panels cracked due to uneven frame support, and the entire structure required major repairs. We replaced the system with marine-grade aluminum alloy framing specifically designed for coastal conditions. Eight years later, the structure shows no signs of corrosion and has survived multiple typhoons without damage.

Thermal expansion compatibility between frame and glazing materials prevents stress-related failures during daily temperature cycles. Aluminum and glass have similar thermal expansion coefficients, reducing stress buildup during heating and cooling. Steel frames expand at different rates than glass, creating pressure points that can crack panels over time. Proper gasket systems and glazing details accommodate remaining expansion differences while maintaining weatherproof seals.

Connection methods between frame members determine overall structural integrity and assembly efficiency. Welded connections provide maximum strength but require skilled labor and quality control during fabrication. Bolted connections allow easier assembly and future modifications but need proper torque specifications and periodic inspection. Hybrid systems combine welded main structures with bolted glazing bars to optimize both performance and serviceability.

Wind load analysis becomes critical in areas prone to severe weather events. Coastal regions, mountain valleys, and open plains experience higher wind loads than sheltered locations. Frame spacing, member sizes, and connection details must match expected loads based on local building codes and historical weather data. Inadequate structural design leads to catastrophic failures during storms, creating safety hazards and total crop losses.

Foundation design must complement frame systems to ensure proper load transfer and structural stability. Lightweight aluminum frames require different foundation approaches than heavy steel systems. Soil conditions, frost depth, and drainage requirements all influence foundation design. Poor foundations can cause frame distortion that leads to glass stress concentration and premature failure.

Quality control during manufacturing and installation affects long-term structural performance significantly. Precise fabrication tolerances ensure proper fit and load distribution. Installation procedures must follow engineering specifications to achieve design performance. Regular inspection and maintenance programs identify potential problems before they cause structural failures or safety hazards.

| Frame Material | Strength/Weight | Corrosion Resistance | Maintenance | Lifespan | Relative Cost |

|---|---|---|---|---|---|

| Carbon Steel | High/Heavy | Poor | High | 10-15 years | 1.0x |

| Galvanized Steel | High/Heavy | Good | Medium | 15-20 years | 1.3x |

| Stainless Steel | High/Heavy | Excellent | Low | 30+ years | 3.0x |

| Aluminum Alloy | High/Light | Excellent | Low | 25-30 years | 1.8x |

Understanding Greenhouse Glass Technical Parameters: Heat Transfer Coefficient and Service Life?

Hidden thermal losses through inadequate glazing can double your heating costs while shortening equipment life. Understanding performance parameters protects both energy budgets and long-term investments.

Heat transfer coefficients (U-values) measure thermal efficiency, with modern insulated glass achieving 1.6-2.8 W/m²K compared to 5.8 W/m²K for single glass. Proper selection reduces heating costs by 60-75% while extending system life to 25+ years.

Thermal performance measurement involves understanding how heat transfers through glazing systems via conduction, convection, and radiation. Conduction occurs when heat moves directly through solid materials like glass and frame components. Convection involves heat transfer through air movement within glazing cavities or around surfaces. Radiation transfers heat through electromagnetic energy emission and absorption. Effective glazing systems must control all three heat transfer mechanisms.

Single-layer glass dominated early greenhouse construction due to cost considerations and limited understanding of thermal performance impacts. As energy costs increased and environmental regulations tightened, the industry recognized that initial glazing savings were quickly offset by higher operational costs. Modern cultivation requirements for precise climate control also demand better thermal performance than single glass can provide.

The evolution from single to multiple glazing layers creates insulating air spaces that dramatically improve thermal performance. Double-glazed units trap air between glass layers, reducing heat transfer through convection and conduction. The optimal air gap width balances insulation performance against structural requirements and costs. Gaps smaller than 6mm allow convection currents that reduce efficiency. Gaps larger than 20mm also permit convection while requiring stronger frame systems.

I worked with a research facility in northern Canada that needed precise temperature control for plant breeding experiments. Their original single-glass greenhouse consumed over $80,000 annually in heating costs during harsh winters. Temperature fluctuations also affected research accuracy and plant health. We designed a replacement glazing system using triple-glazed units with low-emissivity coatings and argon gas filling. Heating costs dropped by 70%, and temperature stability improved dramatically. The controlled environment allowed researchers to conduct more accurate experiments with consistent, repeatable results.

Gas filling between glass layers improves thermal performance beyond air-filled units through reduced thermal conductivity. Argon gas has approximately 34% lower thermal conductivity than air, reducing heat transfer through insulated glass units. Krypton gas offers even better performance with 50% lower conductivity but costs significantly more. For most commercial applications, argon-filled units provide optimal cost-performance balance.

Low-emissivity coatings add another layer of thermal control by reflecting long-wave infrared radiation back into the greenhouse while allowing visible light to pass through normally. These microscopic metallic coatings target specific wavelengths responsible for radiative heat loss without blocking photosynthetically active radiation. Advanced selective coatings can reduce heat transfer by 30-40% while maintaining over 85% visible light transmission.

Service life depends on multiple factors including glass quality, frame design, installation methods, and environmental conditions. High-quality tempered glass in properly engineered frames can last 25-30 years with minimal performance degradation. Poor-quality materials or improper installation may show problems within 5-10 years. Regular maintenance and inspection programs help identify potential issues before they cause system failures.

Edge seal integrity determines insulated glass unit longevity and thermal performance retention. Primary seals prevent moisture infiltration and gas leakage while secondary seals provide structural support and weather protection. Seal failure allows moisture to enter between glass layers, creating condensation that reduces light transmission and thermal performance. Quality manufacturers use proven materials and rigorous testing to ensure long-term seal integrity.

Environmental factors affect glazing system durability differently across various climates and applications. Coastal environments with salt air require special attention to frame materials and seal compatibility. Desert regions with extreme temperature swings stress glass and seals through repeated expansion cycles. Tropical climates with high humidity and intense UV radiation can degrade some materials faster than temperate conditions. Professional suppliers select appropriate materials and designs for specific environmental conditions.

| Glazing Configuration | U-Value (W/m²K) | Light Transmission | Service Life | Energy Savings | Payback Period |

|---|---|---|---|---|---|

| Single Tempered | 5.8 | 90-92% | 20-25 years | Baseline | N/A |

| Double Glazed | 2.8 | 82-85% | 20-25 years | 50-60% | 3-4 years |

| Low-E Double | 2.0 | 78-82% | 25-30 years | 65-70% | 2-3 years |

| Triple Glazed | 1.6 | 75-78% | 25-30 years | 70-75% | 4-5 years |

| Advanced Low-E | 1.2 | 80-85% | 25-30 years | 75-80% | 3-4 years |

Conclusion

Optimal greenhouse glass selection balances maximum light transmission with superior thermal performance and long-term durability, creating efficient growing environments that maximize both crop yields and operational profitability.