Extreme heat kills crops faster than any other greenhouse threat. Without proper cooling systems, your plants will suffer heat stress, reduced yields, and total production failure.

Tropical greenhouse cooling requires integrated solutions combining 6-meter shoulder heights, natural ventilation, evaporative cooling, and strategic shading. Proper system design maintains 25-30°C growing temperatures even when outside temperatures exceed 40°C.

Working in tropical and subtropical climates for over 28 years has taught me that cooling represents the greatest challenge in hot climate greenhouse design. Unlike temperate regions where heating dominates energy costs, tropical facilities must remove enormous amounts of heat while maintaining optimal growing conditions. The physics of heat removal becomes exponentially more difficult as temperature differences between inside and outside decrease.

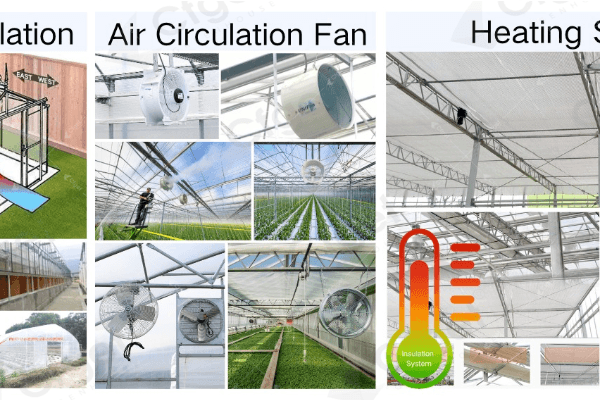

Greenhouse Ventilation: Natural vs. Fan Ventilation, Which is Better for You?

Poor ventilation choices trap deadly heat inside your greenhouse and create stagnant air that promotes disease. The wrong system wastes energy while failing to protect your crops.

Natural ventilation works best for facilities under 2000m² with consistent wind patterns, while fan ventilation suits larger operations or calm locations. Hybrid systems combining both approaches provide optimal performance and energy efficiency.

Natural ventilation relies on temperature differences and wind pressure to drive air movement through strategically placed openings. Hot air rises naturally, creating stack effect that draws cooler outside air through lower vents while exhausting heated air through roof openings. This passive system requires no energy input but depends entirely on favorable weather conditions and proper greenhouse design.

The effectiveness of natural ventilation depends on multiple factors including greenhouse orientation, vent sizing, and local wind patterns. Roof vents should comprise at least 20% of floor area for adequate air exchange, with side vents providing an additional 15-20%. Vent placement must consider prevailing wind directions to maximize pressure differentials that drive air movement. Continuous ridge vents work better than intermittent openings for creating uniform air flow patterns.

I worked with a vegetable grower in southern Thailand who initially relied entirely on natural ventilation for his 1500m² facility. During calm weather periods, temperatures inside reached 45°C while outside temperatures were only 35°C. Plants showed severe heat stress, and yields dropped by 40% during the hottest months. We added exhaust fans and circulation fans to supplement natural ventilation during low-wind conditions. The hybrid system maintained acceptable temperatures year-round while using minimal energy during favorable weather periods.

Fan ventilation systems use mechanical equipment to force air movement regardless of weather conditions. Exhaust fans create negative pressure that draws outside air through inlet vents, while circulation fans improve air mixing and eliminate hot spots. Properly designed fan systems can maintain target temperatures even during extreme weather conditions, but energy costs can become significant in large facilities.

Sizing calculations for fan ventilation must account for heat loads from solar gain, plant respiration, and equipment operation. Standard practice requires 8-12 air changes per hour for adequate cooling, but this may increase to 15-20 changes during extreme conditions. Fan capacity should match inlet vent area to prevent excessive pressure drops that reduce efficiency and increase operating costs.

Energy efficiency considerations favor natural ventilation when conditions permit adequate performance. Fan systems consume 2-5 kW per 1000m² of greenhouse area during peak operation, creating significant electrical costs. However, the crop protection benefits usually justify these costs when natural ventilation cannot maintain acceptable conditions.

Maintenance requirements differ significantly between natural and fan systems. Natural ventilation requires periodic cleaning and adjustment of vent mechanisms but has no moving parts requiring regular service. Fan systems need motor maintenance, belt replacement, and cleaning of louvers and screens. Proper maintenance scheduling prevents system failures during critical cooling periods.

Climate analysis helps determine optimal ventilation approaches for specific locations. Areas with consistent trade winds favor natural ventilation systems with properly oriented vents. Locations with calm periods or variable wind directions benefit from fan backup systems. Extreme climates may require full mechanical ventilation regardless of natural conditions.

| Ventilation Type | Energy Use | Maintenance | Effectiveness | Best Applications |

|---|---|---|---|---|

| Natural Only | Zero | Low | Variable | Small, windy locations |

| Fan Only | High | Medium | Consistent | Large, calm locations |

| Hybrid System | Medium | Medium | Excellent | Most applications |

| Evaporative Cooling | Medium | High | Maximum | Dry climates only |

The Art of Shading: Choosing the Right Shade Net or Curtain to Optimize Light?

Excessive solar radiation burns plants and overheats greenhouses, but too much shading reduces photosynthesis and crop quality. Finding the perfect balance requires understanding both plant needs and climate conditions.

Shade levels of 30-50% work best for most tropical crops, with adjustable systems providing optimal flexibility. Aluminized screens reflect heat while maintaining light quality, while black nets provide simple, cost-effective shading.

Solar radiation in tropical regions can exceed 1200 W/m² during peak hours, creating excessive heat loads and potential plant damage. Direct sunlight at these intensities can cause leaf burn, flower drop, and fruit scalding in sensitive crops. However, plants still require adequate light for photosynthesis, making shade selection a critical balance between protection and productivity.

Different shading materials provide varying levels of heat reflection and light transmission. Black shade nets absorb solar energy and re-radiate it as heat, providing simple light reduction but limited cooling benefit. Aluminized screens reflect solar energy away from the greenhouse, reducing both light levels and heat gain more effectively. White or silver screens offer intermediate performance between black nets and aluminized materials.

Shade percentages must match crop requirements and local solar conditions. Leafy greens like lettuce and herbs can tolerate 50-70% shade while maintaining adequate growth rates. Fruiting crops like tomatoes and peppers typically need 30-40% shade to prevent heat stress while supporting fruit development. Flowers often require 40-60% shade depending on species and market quality requirements.

I worked with an orchid grower in Malaysia who struggled with flower quality during the intense dry season. His fixed 40% black shade net provided adequate light reduction but insufficient cooling. Greenhouse temperatures still exceeded 35°C, causing flower damage and reduced bloom quality. We replaced his system with 50% aluminized screens that reflected more heat while providing similar light levels. Interior temperatures dropped by 4°C, and flower quality improved dramatically during subsequent growing cycles.

Adjustable shading systems provide optimal flexibility for varying weather conditions and seasonal changes. Retractable screens can open during cloudy periods to maximize available light while closing during intense sunshine for plant protection. Automated systems use light sensors and temperature controls to optimize shading throughout the day without manual intervention.

Installation methods affect both shading performance and system durability. External shading provides better cooling by preventing solar energy from entering the greenhouse, but screens face harsh weather conditions that may reduce lifespan. Internal shading protects screens from weather damage but allows solar heat to enter the greenhouse before being blocked.

Ventilation integration becomes critical when using shading systems. Reduced air movement under shade screens can create stagnant conditions that promote disease development. Adequate ventilation must be maintained even with shading in place. Some screen materials incorporate ventilation strips or perforations that allow air movement while providing shade.

Seasonal adjustment strategies optimize shading performance throughout the year. Higher shade levels during peak summer months protect against extreme conditions while lower levels during cooler periods maximize light availability. Some operations use multiple screen layers that can be deployed individually or in combination based on conditions.

Economic analysis must consider both initial costs and long-term benefits of different shading approaches. Simple black nets cost least initially but may require more frequent replacement and provide limited cooling benefit. Aluminized screens cost more but last longer and provide better performance. Automated systems require significant investment but reduce labor costs and optimize performance continuously.

| Shading Material | Light Reduction | Heat Reflection | Durability | Relative Cost |

|---|---|---|---|---|

| Black Net | 30-90% | Low | 3-5 years | 1.0x |

| White Net | 30-90% | Medium | 4-6 years | 1.2x |

| Aluminized Screen | 30-80% | High | 5-8 years | 2.5x |

| Retractable System | Variable | Variable | 8-12 years | 4.0x |

Besides Cooling, What’s the Importance of Drip Irrigation in Hot Climate Greenhouses?

Water stress amplifies heat damage and destroys crops even when temperatures remain manageable. Proper irrigation becomes critical for plant survival in extreme heat conditions.

Drip irrigation provides precise water delivery while enabling evaporative cooling through misting systems. Plants in hot climates require 50-100% more water than temperate conditions, making efficient delivery essential for survival.

Water management in hot climate greenhouses involves multiple interconnected challenges beyond simple irrigation scheduling. High temperatures increase plant water consumption through transpiration while reducing water availability through evaporation. Soil temperatures can exceed optimal root zone conditions, requiring cooling strategies that conventional irrigation cannot provide. Salt accumulation from rapid evaporation creates additional stress that compounds heat damage.

Evapotranspiration rates in tropical greenhouses can reach 8-12 liters per square meter per day compared to 3-5 liters in temperate climates. This dramatic increase in water demand requires irrigation systems with much higher capacity and more frequent delivery cycles. Conventional sprinkler systems cannot provide adequate water volumes without creating humidity problems that promote disease development.

Drip irrigation systems deliver water directly to root zones with minimal evaporation losses, maximizing irrigation efficiency in hot conditions. Emitter spacing and flow rates must be adjusted for higher water requirements while maintaining uniform distribution. Multiple irrigation cycles throughout the day prevent water stress during peak heat periods when plant demand exceeds soil water availability.

I worked with a pepper grower in northern Australia who experienced severe yield losses during extreme heat waves despite adequate irrigation scheduling. His overhead sprinkler system could not deliver sufficient water without creating excessive humidity that promoted fungal diseases. We installed a high-capacity drip system with micro-sprinklers for supplemental cooling. Water use efficiency improved by 40%, and yields increased by 25% during subsequent hot seasons.

Root zone cooling becomes possible through strategic irrigation timing and techniques. Pre-dawn irrigation cycles cool soil temperatures before daily heating begins. Frequent light applications throughout the day maintain soil moisture while providing evaporative cooling around root zones. Mulching materials help retain soil moisture and moderate temperature fluctuations.

Fertigation integration allows precise nutrient delivery despite challenging growing conditions. High temperatures and frequent irrigation can leach nutrients from soil, requiring more frequent fertilizer applications. Drip systems enable continuous low-level feeding that maintains optimal nutrition without salt accumulation problems. Electrical conductivity monitoring helps prevent over-fertilization that compounds heat stress.

Water quality considerations become more critical in hot climates where evaporation concentrates salts and other dissolved materials. High-quality water sources reduce salt accumulation problems while poor water quality can create additional plant stress. Water treatment systems may be necessary to remove excess salts, adjust pH, or eliminate harmful microorganisms.

Misting systems integrated with drip irrigation provide additional cooling through evaporative heat removal. Fine mist nozzles create humidity around plants while larger droplets provide direct cooling. Timing controls prevent excessive humidity during disease-prone periods while maintaining cooling benefits during peak heat stress.

System redundancy becomes essential in hot climates where irrigation failures can destroy crops within hours. Backup pumps, alternate water sources, and emergency irrigation protocols protect against system failures during critical periods. Monitoring systems alert operators to problems before crop damage occurs.

Automation systems optimize irrigation timing and duration based on environmental conditions and plant needs. Soil moisture sensors, weather stations, and plant monitoring equipment provide data for precise irrigation control. Automated systems respond to changing conditions faster than manual management while reducing labor requirements during extreme weather periods.

| Irrigation Factor | Temperate Climate | Hot Climate | Increase Factor | Management Impact |

|---|---|---|---|---|

| Daily Water Use | 3-5 L/m² | 8-12 L/m² | 2.5x | Higher capacity needed |

| Irrigation Frequency | 1-2 times/day | 4-8 times/day | 4x | More automation required |

| System Pressure | 1.5-2.0 bar | 2.0-3.0 bar | 1.5x | Stronger pumps needed |

| Emitter Flow Rate | 2-4 L/hr | 4-8 L/hr | 2x | Larger emitters required |

Greenhouse Structure and Siting: How to Use Natural Conditions to Aid Cooling?

Poor greenhouse orientation and design trap heat and create unbearable growing conditions. Smart siting and structural choices can reduce cooling loads by 30-50% through natural climate advantages.

Optimal greenhouse orientation runs east-west with 6-meter shoulder heights to promote natural ventilation. Strategic placement near water bodies or elevation changes enhances cooling while protection from hot winds reduces heat loads.

Site selection represents the most important decision for hot climate greenhouse success, yet it receives insufficient attention in many projects. Microclimate variations within small areas can create temperature differences of 5-8°C that dramatically affect cooling requirements. Elevation changes, water bodies, vegetation patterns, and wind exposure all influence local conditions that impact greenhouse performance.

Greenhouse orientation affects solar heat gain throughout the day and across seasons. East-west orientation minimizes roof area exposed to intense midday sun while maximizing morning and afternoon light when temperatures are more moderate. North-south orientation exposes the entire roof to peak solar radiation but provides more uniform light distribution inside the greenhouse.

Building height directly affects natural ventilation potential through stack effect and wind exposure. Standard greenhouse heights of 3-4 meters limit natural cooling effectiveness in hot climates. Increasing shoulder height to 6 meters or more creates stronger thermal gradients that drive natural air movement while providing larger air volumes that moderate temperature swings.

I worked on a project in central Thailand where site constraints limited greenhouse placement options. The initial location in a valley bottom experienced stagnant air conditions and temperature extremes that made cooling extremely difficult. We relocated the facility 50 meters uphill where prevailing breezes provided natural air movement. The elevation change reduced cooling energy requirements by 35% while improving growing conditions significantly.

Wind pattern analysis reveals opportunities for natural cooling assistance or identifies problems requiring mitigation. Consistent breezes from cooler directions can be channeled through greenhouse designs to enhance natural ventilation. Hot winds from desert or urban areas may require windbreaks or greenhouse orientation adjustments to minimize heat gain.

Water body proximity provides natural cooling through evaporative effects and moderated air temperatures. Lakes, rivers, or irrigation ponds create cooler microclimates that benefit nearby greenhouses. However, water bodies also increase humidity levels that may create other management challenges. Distance and orientation relative to water features affect the balance of benefits and drawbacks.

Vegetation and landscaping around greenhouse sites influence local temperatures and air movement patterns. Trees and shrubs provide shade and evaporative cooling but may block beneficial breezes or create stagnant air pockets. Strategic landscaping can channel cooling breezes while providing shade for areas that don’t require full sun exposure.

Thermal mass integration helps moderate temperature swings through heat absorption and release cycles. Concrete floors, water storage tanks, or stone walls absorb excess heat during hot periods and release it during cooler times. Proper thermal mass placement and sizing can reduce peak temperatures while maintaining warmer nighttime conditions when needed.

Structural design features enhance natural cooling through improved air movement and heat rejection. Ridge vents, side wall openings, and internal air circulation pathways must be sized and positioned to maximize natural ventilation effectiveness. Roof slopes, overhang designs, and wall configurations all affect air flow patterns and solar heat gain.

Ground coupling systems use stable soil temperatures to moderate greenhouse conditions through buried heat exchange pipes. These systems work best in climates with significant temperature differences between surface and subsurface conditions. Installation costs are high but operating costs remain low since the systems use minimal energy.

Regional building codes and agricultural regulations may influence structural choices for hot climate greenhouses. Wind load requirements, seismic considerations, and agricultural use restrictions all affect design options. Professional design services ensure compliance while optimizing performance for local conditions.

| Siting Factor | Temperature Impact | Ventilation Effect | Implementation Cost | Payback Period |

|---|---|---|---|---|

| Elevation +50m | -2 to -4°C | +30% air flow | Site dependent | Immediate |

| Water Body 100m | -1 to -3°C | Variable | Low | 1-2 years |

| Wind Protection | -3 to -6°C | Improved patterns | Medium | 2-3 years |

| Optimal Orientation | -2 to -5°C | +20% natural vent | Design only | Immediate |

Conclusion

Successful tropical greenhouse cooling requires integrated solutions combining optimal siting, natural ventilation, strategic shading, and efficient irrigation systems that work together to maintain productive growing conditions despite extreme heat.