Struggling to pick the perfect glass for your greenhouse? Feeling overwhelmed by the options and technical terms? You need clarity to ensure your crops thrive and your investment pays off.

Selecting the best glass involves matching the material’s properties, like light transmission and insulation, to your climate, crops, and budget. Key options include single-pane, double-glazed, tempered, and diffused glass, each offering distinct advantages for specific growing needs and environmental conditions.

Making the right choice in greenhouse glazing is crucial. It affects everything from plant growth and energy costs to the structure’s longevity. We’ve spent years helping growers navigate these decisions, and I want to share some practical insights to simplify the process for you. Let’s break down the types of glass, compare them to alternatives, and look at the vital properties you need to consider.

Don’t Miss:——Is Commercial Greenhouse Farming Really a Profitable Business Opportunity?

Exploring Different Types of Glass for Greenhouse Construction?

Wondering what glass options are actually available for greenhouses? Confused about terms like ‘tempered’ or ‘diffused’? Getting the right type is key for successful growing, avoiding costly mistakes later.

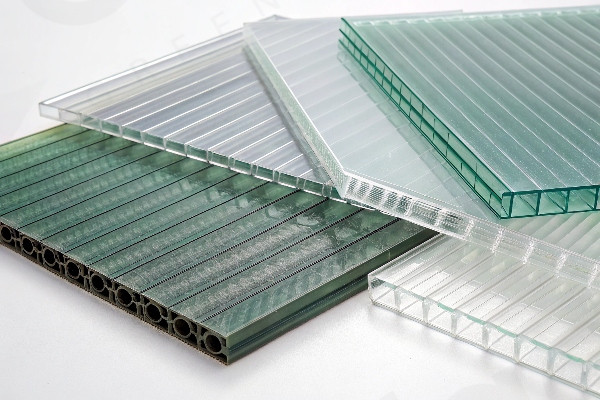

Common greenhouse glass includes standard annealed (single or double-glazed), tougher tempered safety glass, and light-scattering diffused glass. Each type varies in strength, light quality, insulation, and cost, impacting suitability for different climates and crops.

When we talk about glass greenhouses, the term ‘glass’ covers several materials. The choice isn’t just about transparency; it’s about optimizing the growing environment. For instance, the glass on the sides might differ from the roof glazing. In my experience working with clients across various regions, from Southeast Asia to Central Asia, the local climate plays a huge role. In milder zones, single-layer annealed glass might seem cost-effective initially. It offers excellent light transmission, which is great for many crops. However, it provides minimal insulation. I remember a project in a region with moderate temperatures where single-pane glass worked well for basic vegetable production, keeping initial costs down. But, for areas with distinct cold seasons, this option leads to high heating bills. That’s where double-glazing, often called hollow laminated glass or insulated glass units (IGUs), comes in. These units trap air or gas between two panes, significantly boosting insulation and reducing energy consumption.

| Glass Type | Key Feature | Best For | Considerations |

|---|---|---|---|

| Annealed Glass | Standard, basic | Mild climates, budget projects | Lower insulation, breaks into shards |

| Tempered Glass | Safety, strength | Areas prone to hail/impact, public spaces | Higher cost than annealed |

| Double-Glazed (IGU) | Insulation | Cold climates, energy efficiency | Higher initial cost, heavier |

| Diffused Glass | Light scattering | High-light areas, sensitive crops | Reduces direct light intensity |

| Low-E Coated Glass | Heat reflection | Hot climates (reflects heat out), Cold (in) | Cost, specific coating types |

| Patterned Glass | Textured surface | Sometimes used for diffusion/aesthetics | Light transmission varies |

Further options involve treatments and specific structures. Tempered glass is heat-treated to be much stronger than standard annealed glass. When it breaks, it shatters into small, relatively harmless pebbles, making it a safer option, especially for roofs or high-traffic areas. Then there’s diffused glass. It often has a micro-textured surface, looking somewhat like frosted glass. We typically recommend this for the roof in high-light intensity regions. Why? It scatters the incoming sunlight, softening it and reducing harsh shadows inside the greenhouse. This uniform light distribution benefits many crops, especially flowers and leafy greens, preventing scorching on upper leaves and ensuring lower leaves get adequate light. Low-Emissivity (Low-E) coatings can also be applied, usually to double-glazed units, to further enhance insulation by reflecting heat radiation – keeping heat inside during winter and outside during summer. The choice depends heavily on balancing light needs, temperature control, safety, and budget.

Don’t Miss:——Sustainable Agriculture: Is the Role of Smart Greenhouses Key to a Greener Future?

Greenhouse Glass vs. Polycarbonate: Which Glazing Material is Best?

Torn between the classic look of glass and the modern appeal of polycarbonate? Worried about durability, light, or cost differences? Choosing incorrectly can impact crop quality and operational expenses.

Glass offers superior light transmission, longevity (often 20+ years), and doesn’t yellow. Polycarbonate provides better insulation per thickness, higher impact resistance, and is lighter, but typically has a shorter lifespan and can scratch or yellow.

This is a frequent question from clients, especially those in areas with extreme weather or those prioritizing safety and insulation. Both glass and polycarbonate have their place in greenhouse construction, and the "best" choice really depends on specific priorities. Let’s look at them side-by-side. Glass, particularly single-pane, offers the highest light transmission, typically around 88-90%. This clarity is fantastic for crops needing maximum sunlight, like tomatoes or roses. As mentioned in my insights, glass is incredibly durable in terms of its material properties; unless physically damaged by impact or extreme stress, its clarity and structure can last for decades – I’ve seen glass greenhouses still performing well after 20-25 years. It doesn’t degrade under UV light or easily scratch compared to plastics. However, standard glass can be brittle and heavy, requiring a stronger, potentially more expensive, support structure. Installation also requires more care.

Polycarbonate, on the other hand, is a type of strong plastic. Its biggest advantages are impact resistance (it’s virtually unbreakable, making it ideal for areas with hail or risk of vandalism) and better insulation compared to single-pane glass (especially multi-wall polycarbonate). A standard twin-wall polycarbonate panel might offer insulation similar to double-glazed glass but at a lower weight. This reduced weight can sometimes allow for a lighter, less expensive frame. It’s also easier and safer to handle and cut during installation. However, polycarbonate’s light transmission is slightly lower than glass (around 80-85% for twin-wall) and it degrades over time when exposed to UV radiation, often leading to yellowing and reduced light transmission within 10-15 years, though UV-protected options last longer. It’s also more susceptible to scratching, which can further reduce light clarity. I often advise clients in regions like Central Asia, where durability against harsh weather is key, to strongly consider polycarbonate for its impact resistance, while clients in Europe focusing on high light crops and longevity might lean towards glass, potentially double-glazed for energy savings.

| Feature | Glass (Single Pane) | Glass (Double Glazed) | Polycarbonate (Twin-Wall) |

|---|---|---|---|

| Light Transmission | Highest (88-90%) | High (75-85%) | Good (80-85%) |

| Insulation (R-Value) | Low (~0.9) | Good (~1.5-2.0+) | Good (~1.5-1.7+) |

| Durability/Lifespan | Very Long (20+ years) | Very Long (20+ years) | Medium (10-15+ years) |

| Impact Resistance | Low (breaks easily) | Low (breaks easily) | Very High |

| Weight | Heavy | Very Heavy | Light |

| UV Degradation | None | None | Yes (can yellow/brittle) |

| Scratch Resistance | High | High | Low |

| Cost (Material) | Moderate | High | Moderate to High |

| Diffusion | Low (unless diffused type) | Low (unless diffused type) | Can be higher |

Ultimately, the decision often comes down to balancing initial cost, desired lifespan, light requirements, insulation needs, and safety concerns. For a commercial operation planning long-term, the longevity and clarity of glass, especially double-glazed for insulation, can be a worthwhile investment despite the higher upfront cost. For hobbyists, or in applications where impact is a major concern, polycarbonate offers a compelling alternative. We once helped a research institution choose polycarbonate for a rooftop greenhouse specifically because of weight limitations and the risk of falling debris – glass would have been too heavy and potentially hazardous.

Understanding Glass Properties: Light Transmission, Insulation, and Durability?

Do terms like R-value, U-value, or PAR light leave you confused? Not grasping these properties means you might choose glass that hinders growth or inflates energy bills. Understanding them is key to an efficient greenhouse.

Key glass properties include: Light Transmission (how much light gets through, including PAR), Insulation (measured by R-value or U-value, indicating heat retention), and Durability (resistance to breakage and environmental factors like UV light, ensuring longevity).

Let’s delve into these critical properties because they directly impact your greenhouse’s performance and running costs. First, light transmission. It’s not just about overall brightness; it’s about the specific wavelengths plants use for photosynthesis, known as Photosynthetically Active Radiation (PAR), typically in the 400-700 nanometer range. Standard clear glass excels here, allowing maximum light, including PAR, to reach the plants. However, as mentioned, intense direct sunlight can sometimes be too much, causing stress or burning. This is where diffused glass becomes valuable. By scattering light, it creates a more uniform illumination throughout the canopy, reducing shadows and potentially increasing overall photosynthesis, even if the total transmission percentage is slightly lower than clear glass. I’ve seen impressive results in flower production under diffused glass in sunny climates – fewer hotspots and more consistent growth.

Next is insulation. This is crucial for controlling temperature and managing energy costs, especially in climates with cold winters or hot summers. Insulation is typically measured by R-value (higher means better insulation) or U-value (lower means better insulation – it measures heat transfer). Single-pane glass has a very low R-value1 (around 0.9), meaning heat escapes easily. Double-glazed units significantly improve this (R-value 1.5 to 2.0 or more), trapping air or an inert gas like argon between the panes to slow heat transfer. Low-E coatings2 on double-glazed units3 can further boost the R-value by reflecting thermal radiation. Choosing glass with the right insulation level is vital. A client in Northern Europe drastically cut heating costs after upgrading from single-pane to Low-E double-glazed units, making the higher initial investment pay back quickly.

| Property | What it Means | Why it Matters | Typical Values/Considerations |

|---|---|---|---|

| Light Transmission | Percentage of total light passing through | Plant growth, photosynthesis (PAR light is key) | Clear Glass: ~90%, Double Glazed: ~80%, Diffused: Varies |

| Insulation (R-Value) | Resistance to heat flow (Higher is better) | Energy savings (heating/cooling), temperature stability | Single Glass: ~0.9, Double Glazed: ~1.5-2.0+, Poly: ~1.5-1.7+ |

| Insulation (U-Value) | Rate of heat transfer (Lower is better) | Energy savings, temperature stability | Inverse of R-Value (approx.) |

| Durability | Resistance to breakage, UV, weathering | Lifespan, safety, maintenance costs | Glass: High UV/weather resistance, brittle. Tempered=stronger |

| Diffusion | Scattering of light | Reduces shadows, prevents scorching, uniform light | Specific diffused glass types offer varying levels |

| Weight | Mass per unit area | Structural frame requirements, installation ease | Glass is heavy, requires robust support structure |

Finally, durability relates to both physical strength and resistance to environmental degradation. Standard annealed glass is brittle. Tempered glass is much stronger and safer upon breakage. Glass itself is highly resistant to UV radiation and weathering – it won’t yellow, cloud, or become brittle like some plastics over its lifespan. As noted in my initial thoughts, a well-maintained glass greenhouse structure can easily last over 20 years, often much longer. This longevity is a significant factor when considering the total cost of ownership. The structure supporting the glass, usually galvanized steel or aluminum, also needs to be robust enough to handle the weight of the glass, plus potential snow or wind loads, particularly for double-glazed units which are heavier. This interaction between the glazing choice and the required structure (like the Venlo or wide-span styles mentioned earlier) is a key design consideration we always address early in a project.

Cost Considerations for Greenhouse Glass Options?

Worried about the budget for your greenhouse project? Does the price of glass seem prohibitive compared to other options? Balancing cost and quality is essential for a sustainable and profitable operation.

Greenhouse glass costs vary significantly based on type (single vs. double-glazed, tempered, diffused, Low-E), thickness, and required structural support. While potentially having a higher initial cost than some alternatives, glass offers long-term value through durability and light clarity.

Budget is always a major factor in any greenhouse project, whether it’s for a small-scale grower or a large agricultural producer. When looking at glass, it’s important to consider both the upfront material and installation costs and the long-term operational costs and value. Single-layer annealed glass generally has the lowest initial material cost among glass options. However, its poor insulation means higher heating costs in cooler climates, potentially negating the initial savings over time. I always encourage clients to think about the total cost of ownership. For example, investing in double-glazed units3 significantly increases the upfront cost – sometimes nearly double that of single-pane glass – plus, the heavier weight might require a stronger, more expensive frame. But, the energy savings in heating (and sometimes cooling) can lead to a payback period of just a few years, especially with rising energy prices. We calculated for a grower in Central Asia that the extra investment in double-glazing would pay for itself within 5-7 years purely through reduced fuel consumption for heating.

Beyond the basic type, specific features add to the cost. Tempered glass is more expensive than annealed glass due to the additional heat treatment process. Diffused glass and glass with Low-E coatings2 also carry premiums because of the specialized manufacturing involved. The thickness of the glass matters too; standard greenhouse glass is often 4mm, but thicker options might be needed for larger panes or higher load requirements, increasing cost. Installation costs for glass are also typically higher than for lighter materials like polycarbonate or film, requiring more skilled labor and careful handling. However, the longevity factor is where glass often shines in terms of long-term value. With a lifespan potentially exceeding 25 years without significant degradation in light transmission, the cost per year can be very competitive compared to materials that need replacing every 10-15 years.

| Factor | Impact on Cost | Considerations |

|---|---|---|

| Glass Type | Single < Tempered < Double Glazed < Low-E/Diffused | Balance initial cost with long-term needs (insulation, safety, light quality). |

| Glass Thickness | Thicker glass costs more | Determined by pane size, structural requirements, load factors (wind/snow). |

| Insulation Level | Higher R-value1 (e.g., double-glazing) costs more | Offset by potential energy savings; crucial in extreme climates. |

| Special Features | Tempering, Low-E coatings, diffusion add cost | Justify based on specific needs (safety, energy efficiency, crop quality). |

| Structure | Heavier glass requires stronger, costlier frame | Factor frame costs into the total glazing system budget. |

| Installation | Glass requires careful handling, skilled labor | Typically higher installation cost compared to polycarbonate or film. |

| Longevity | Higher initial cost amortized over long life (20+yr) | Compare cost per year of service vs. materials needing frequent replacement. |

| Maintenance | Low material degradation, cleaning required | Factor in cleaning costs; glass is less prone to scratching than plastics. |

Therefore, when evaluating cost, look beyond the price tag per square meter. Consider:

- Initial Investment: Material cost + Structural support cost + Installation cost.

- Operational Costs: Primarily energy costs for heating/cooling, influenced by insulation.

- Lifespan & Replacement: How long will the material last before needing replacement and losing performance (like light transmission)?

- Crop Value: Does the superior light quality or specific property (like diffusion) of a particular glass lead to higher yields or quality, justifying a higher cost?

For high-value growers or research institutions, the precision and longevity offered by specific glass types often justify the investment. For others, a careful analysis comparing glass options against alternatives like polycarbonate is essential to find the sweet spot between budget and performance needs.

Conclusion

Choosing the right greenhouse glass involves balancing light, insulation, durability, and cost. Consider your climate, crops, and long-term goals to select the best option for lasting success.

-

Understanding R-value is crucial for making informed decisions about insulation materials, impacting energy efficiency and comfort. ↩ ↩

-

Exploring Low-E coatings can reveal how they enhance insulation and reduce energy costs, making them a smart investment for greenhouses. ↩ ↩

-

Double-glazed units offer significant energy savings and comfort, making them a worthwhile consideration for greenhouse projects. ↩ ↩