Building a greenhouse in scorching desert heat seems impossible. Most people think extreme temperatures make protected cultivation unviable, but smart design can transform harsh climates into productive agricultural zones.

Efficient hot-climate greenhouses require strategic design focusing on maximum ventilation, UV-resistant materials, elevated structures for heat dissipation, and advanced cooling systems. Proper planning can achieve 20-30°C temperature reduction while maintaining optimal growing conditions.

After designing greenhouse systems across Middle Eastern deserts, Southeast Asian tropics, and Australian outback regions, I’ve learned that extreme heat challenges demand innovative solutions. The key is working with natural forces rather than fighting them.

What’s the Primary Consideration in Hot Climate Greenhouse Design? (Ventilation & Shading)

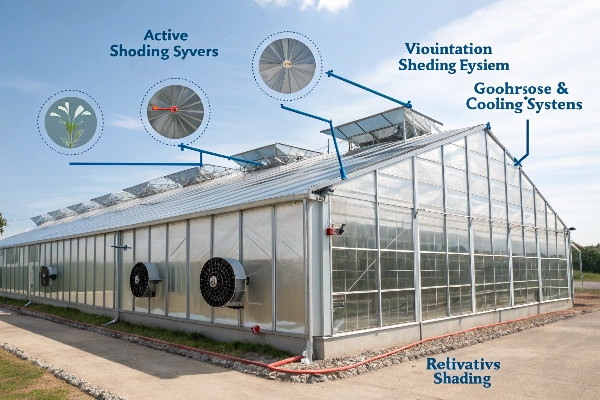

Hot climate greenhouse design prioritizes maximum natural ventilation and strategic shading to prevent heat buildup. The primary goal is creating continuous airflow that removes hot air while providing plant protection from direct solar radiation.

The primary consideration is designing for maximum natural ventilation through elevated structures (6+ meters), large openable roof vents covering 25-30% of floor area, continuous sidewall ventilation, and strategic shading systems that block 40-60% of solar radiation while maintaining airflow.

Structural Height and Heat Dissipation

Greenhouse height becomes critical in hot climates because hot air rises and needs space to dissipate before affecting plants. We design hot-climate greenhouses with shoulder heights of 6 meters or more, compared to 3-4 meters in temperate regions. This extra height creates a thermal buffer zone above the crop canopy.

The physics of heat dissipation favor tall structures. Hot air naturally rises and collects in the upper greenhouse volume, where it can be vented away without directly heating the plants. This natural stratification only works effectively with sufficient vertical space for air separation.

I remember designing a tomato greenhouse in Saudi Arabia where the client initially requested standard 4-meter height to save costs. After explaining the thermal dynamics, we increased height to 6.5 meters. The temperature difference at plant level was remarkable – 8°C cooler than the original design would have achieved.

Roof pitch affects heat accumulation significantly. Steep roof angles (35-40 degrees) promote rapid hot air movement toward ridge vents, while shallow roofs trap hot air. The increased surface area from steeper roofs also provides more space for ventilation openings.

| Design Element | Standard Climate | Hot Climate | Temperature Impact |

|---|---|---|---|

| Shoulder Height | 3-4 meters | 6+ meters | 5-8°C cooler |

| Roof Pitch | 22-26 degrees | 35-40 degrees | Improved air flow |

| Ridge Vent Area | 15-20% of floor | 25-30% of floor | Better heat removal |

| Sidewall Vents | Minimal | Continuous | Enhanced cross-ventilation |

Natural Ventilation Strategies

Cross-ventilation design creates continuous airflow that prevents heat buildup and maintains plant-level temperatures within acceptable ranges. The key is positioning inlet and outlet vents to create pressure differentials that drive air movement even in minimal wind conditions.

Inlet vents should be positioned low on sidewalls to capture cool air, while outlet vents must be placed at the highest points to remove hot air. The total ventilation area should equal 25-30% of the floor area in extreme climates, compared to 15-20% in moderate regions.

Stack effect ventilation uses thermal buoyancy to create airflow when wind is absent. Hot air’s natural tendency to rise creates suction that draws cooler air through lower vents. This principle works reliably in hot climates where temperature differentials are large.

Automated vent control systems respond to temperature and wind conditions to optimize ventilation throughout the day. These systems open vents progressively as temperatures rise and adjust for wind direction changes. The investment in automation pays back through reduced cooling costs and improved crop performance.

Strategic Shading Applications

External shading systems provide the most effective heat reduction by blocking solar radiation before it enters the greenhouse. Fixed or retractable shade structures can reduce internal temperatures by 10-15°C while still providing adequate light for photosynthesis.

Shade cloth selection depends on crop requirements and local solar intensity. In extreme desert conditions, we often use 50-60% shade cloth during peak summer months, reducing to 30-40% during cooler periods. The key is maintaining enough light for healthy plant growth while preventing heat stress.

Retractable shading systems offer flexibility to respond to changing conditions throughout the day and seasons. These systems can open during cooler morning hours for maximum light, then close during peak heat periods. The automation adds cost but provides optimal growing conditions.

Internal shading provides additional temperature control and protects sensitive crops from direct radiation. Aluminum screens reflect heat back outside while diffusing remaining light for better plant distribution. This dual approach maximizes cooling effectiveness.

Which Covering Material is Best for Resisting Extreme Heat and Strong UV Rays?

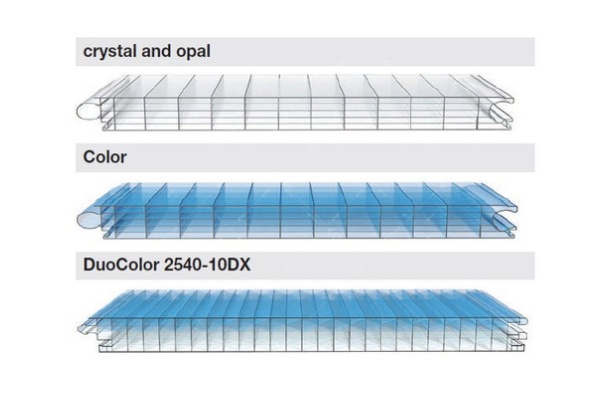

Polycarbonate panels with UV protection and thermal properties provide the best combination of durability, insulation, and UV resistance for extreme heat environments. Multi-wall polycarbonate offers superior thermal performance compared to glass or single-layer materials.

Multi-wall polycarbonate with UV co-extrusion provides optimal hot-climate performance through 99.9% UV blocking, 50% better insulation than glass, impact resistance to 150 kg/m², and 25-year lifespan with minimal degradation under extreme conditions.

Thermal Performance Comparison

Multi-wall polycarbonate creates insulating air chambers that reduce heat transfer by 50% compared to single-layer materials. This insulation works both ways – keeping heat out during hot days and retaining warmth during cool desert nights when temperatures can drop dramatically.

The cellular structure of polycarbonate panels traps air in multiple chambers, creating effective thermal barriers. Twin-wall panels provide good insulation, while triple-wall or honeycomb structures offer maximum thermal protection for extreme climates. The additional insulation reduces cooling costs significantly.

Light transmission remains high (80-85%) while blocking harmful UV radiation completely. This combination allows optimal photosynthesis while protecting both plants and greenhouse structure from UV damage that degrades other materials rapidly in desert conditions.

Thermal expansion characteristics of polycarbonate handle extreme temperature cycling better than rigid materials like glass. Desert environments can experience 40°C daily temperature swings, and polycarbonate’s flexibility accommodates this movement without stress cracking.

| Material Property | Glass | Single Polyethylene | Multi-wall Polycarbonate | Advantage |

|---|---|---|---|---|

| UV Transmission | High (damaging) | Variable | Blocked 99.9% | Plant protection |

| Thermal Insulation | Poor | Poor | Excellent | 50% less cooling |

| Impact Resistance | Low | Moderate | High | Storm survival |

| Lifespan in Desert | 10-15 years | 2-4 years | 25+ years | Long-term value |

UV Protection and Durability

UV co-extrusion technology integrates UV blockers throughout the polycarbonate structure rather than applying surface coatings that can wear away. This provides permanent UV protection that maintains effectiveness throughout the panel’s 25-year lifespan.

Desert UV intensity can be 50% higher than temperate regions, making UV protection critical for both plant health and material longevity. Unprotected materials degrade rapidly, becoming brittle and losing optical clarity within 2-3 years. Quality polycarbonate maintains clarity and strength for decades.

The UV protection extends to greenhouse contents as well. Many plastics, fabrics, and equipment components suffer UV damage in desert greenhouses. Polycarbonate’s UV blocking protects these investments while creating better growing conditions for UV-sensitive crops.

Surface treatments like anti-dust coatings become particularly valuable in desert environments where sandstorms can reduce light transmission by 20-30%. These treatments make cleaning easier and maintain optimal light levels for plant growth.

Installation and Maintenance Advantages

Polycarbonate’s light weight (6 times lighter than glass) reduces structural requirements and installation costs. This weight advantage becomes significant in large greenhouse projects where structural steel costs can represent 30-40% of total investment.

Thermal movement accommodation is built into polycarbonate glazing systems through expansion joints and flexible gaskets. Glass systems require complex thermal break designs that add cost and complexity while still being prone to thermal stress failures.

Maintenance requirements are minimal with quality polycarbonate systems. Unlike glass that requires frequent cleaning and replacement due to thermal stress cracking, polycarbonate maintains performance with basic washing and occasional gasket inspection.

Replacement costs favor polycarbonate significantly in extreme climates. When panels do require replacement after 20+ years, the process is simpler and less expensive than glass replacement. The reduced weight and flexibility make handling safer and faster.

Pad-and-Fan System: An Effective Cooling Solution for Greenhouses in Hot Regions

Pad-and-fan systems provide the most cost-effective mechanical cooling for hot-climate greenhouses by using evaporative cooling principles. These systems can reduce internal temperatures by 10-15°C while maintaining humidity levels suitable for plant growth.

Pad-and-fan systems achieve 80-90% cooling efficiency in dry climates by drawing hot air through water-saturated cooling pads. Properly designed systems can maintain 25-28°C internal temperatures when external temperatures exceed 45°C, using 70% less energy than refrigerated cooling.

Evaporative Cooling Principles

Evaporative cooling works by adding moisture to hot, dry air, which absorbs heat energy during the phase change from liquid to vapor. This process can reduce air temperature by 10-20°C depending on the initial humidity levels. Desert climates with low humidity provide ideal conditions for maximum cooling effectiveness.

The cooling efficiency depends on the wet-bulb temperature differential. In dry desert air with 10% relative humidity at 45°C, evaporative cooling can achieve temperatures as low as 25°C. This represents 80-90% cooling efficiency, making it far more energy-efficient than mechanical refrigeration.

Cooling pad materials affect system performance significantly. Cellulose pads provide excellent cooling efficiency and durability, while synthetic materials offer easier maintenance but lower performance. We typically specify 150mm thick cellulose pads for extreme climate applications to maximize cooling effectiveness.

Water quality impacts system performance and maintenance requirements. High mineral content water leaves deposits that reduce pad efficiency and require frequent cleaning. Water treatment systems often justify their cost through improved cooling performance and reduced maintenance.

| Climate Condition | External Temperature | Humidity | Achievable Internal Temperature | Cooling Efficiency |

|---|---|---|---|---|

| Extreme Desert | 45°C | 10% RH | 25-27°C | 85-90% |

| Moderate Desert | 40°C | 20% RH | 28-30°C | 75-80% |

| Semi-Arid | 38°C | 30% RH | 30-32°C | 65-70% |

| Humid Hot | 35°C | 60% RH | 32-34°C | 40-50% |

System Design and Sizing

Fan capacity must be sized to provide complete air changes every 1-2 minutes in extreme heat conditions. This requires significantly more airflow than temperate climate greenhouses where 3-4 minute air changes are adequate. The increased airflow ensures effective heat removal and uniform cooling distribution.

Pad area calculations depend on air velocity and cooling requirements. Optimal air velocity through pads ranges from 1.5-2.0 meters per second. Higher velocities reduce cooling effectiveness, while lower velocities don’t provide adequate airflow for heat removal.

Distribution uniformity requires careful fan and pad placement to ensure even cooling throughout the greenhouse. Dead air zones create hot spots that stress plants and reduce overall system effectiveness. We use computational fluid dynamics modeling to optimize airflow patterns in large installations.

Backup systems become critical in extreme climates where cooling system failure can destroy crops within hours. Redundant fans, emergency generators, and alarm systems protect valuable crops from equipment failures during peak heat periods.

Installation and Operational Considerations

Water supply systems must provide adequate flow rates and pressure for proper pad saturation. Insufficient water flow creates dry spots that reduce cooling efficiency and can damage pads. We typically design for 3-4 liters per minute per linear meter of pad length.

Drainage systems prevent water accumulation that can cause structural damage and create breeding grounds for pests and diseases. Proper drainage also allows for water recycling systems that reduce operating costs in water-scarce desert regions.

Maintenance schedules must account for the harsh operating environment. Cooling pads require cleaning every 2-3 weeks during peak operating season to maintain efficiency. Fan maintenance includes bearing lubrication and belt tension checks to prevent failures during critical periods.

Seasonal operation strategies optimize energy use and system longevity. Systems typically operate 12-16 hours daily during peak summer months, with reduced operation during cooler periods. Automated controls adjust operation based on temperature and humidity conditions.

Energy-Saving Tips: Using Passive Cooling and Shade Net Houses to Reduce Operational Costs

Passive cooling strategies and shade net houses provide cost-effective alternatives to mechanical cooling systems while maintaining productive growing conditions. These approaches can reduce energy costs by 60-80% compared to fully air-conditioned greenhouses.

Passive cooling combines natural ventilation, thermal mass, ground cooling, and strategic shading to maintain temperatures 8-12°C below ambient without energy consumption. Shade net houses provide 70% of greenhouse benefits at 30% of the cost for many crops.

Thermal Mass and Ground Cooling

Thermal mass systems use materials like water tanks, concrete floors, or rock beds to absorb heat during hot days and release it during cool nights. This thermal flywheel effect moderates temperature swings and reduces peak cooling loads by 20-30%.

Ground-coupled cooling systems take advantage of stable soil temperatures 2-3 meters below surface. Underground air circulation systems can pre-cool incoming ventilation air by 5-8°C using only fan energy. The initial installation cost pays back through reduced cooling expenses.

I designed a ground-cooling system for a flower grower in Arizona that used buried pipes to pre-cool ventilation air. The system reduced peak cooling loads by 35% and paid for itself within three growing seasons through energy savings.

Water thermal mass provides the most effective heat absorption per unit cost. Large water tanks or ponds inside the greenhouse absorb solar energy during the day and release it slowly at night. This system works particularly well in desert climates with large day-night temperature differences.

Phase change materials offer advanced thermal storage in compact systems. These materials absorb large amounts of energy when changing from solid to liquid, providing cooling during hot periods. While more expensive initially, they provide superior performance in limited space applications.

| Passive Cooling Method | Temperature Reduction | Installation Cost | Annual Savings | Payback Period |

|---|---|---|---|---|

| Thermal Mass (Water) | 3-5°C | Low | $2,000-3,000 | 2-3 years |

| Ground Coupling | 5-8°C | Moderate | $4,000-6,000 | 3-4 years |

| Phase Change Materials | 6-10°C | High | $5,000-8,000 | 4-5 years |

| Combined Systems | 8-12°C | Moderate-High | $8,000-12,000 | 3-4 years |

Shade Net House Applications

Shade net houses provide plant protection at a fraction of greenhouse costs while offering many of the same benefits. These structures use shade cloth and simple framing to create controlled growing environments suitable for many crops in hot climates.

Shade cloth selection determines the growing environment inside net houses. Different crops require different shade levels – leafy vegetables thrive under 70-80% shade, while fruiting crops need 40-50% shade. Adjustable systems allow seasonal optimization for changing light and temperature conditions.

Ventilation in shade houses occurs naturally through the mesh structure, eliminating the need for mechanical ventilation systems. This natural airflow prevents heat buildup while maintaining humidity levels suitable for plant growth. The open structure also eliminates many pest and disease problems common in closed greenhouses.

Cost comparisons favor shade houses for many applications. A shade house costs 20-30% of an equivalent greenhouse while providing 70% of the environmental control benefits. For crops that don’t require precise climate control, shade houses offer excellent return on investment.

Crop suitability varies significantly between shade houses and closed greenhouses. Leafy vegetables, herbs, and nursery crops perform excellently in shade houses, while fruiting vegetables and flowers often require the precise control possible only in closed greenhouses.

Integrated Energy-Saving Strategies

Combining multiple passive cooling strategies provides synergistic effects that exceed the sum of individual contributions. A well-designed system using thermal mass, ground cooling, and optimized ventilation can maintain comfortable growing conditions with minimal energy input.

Automated control systems optimize passive cooling effectiveness by responding to weather conditions and plant requirements. These systems can adjust shade levels, ventilation rates, and thermal mass charging cycles to minimize energy use while maintaining optimal growing conditions.

Solar-powered ventilation systems provide cooling airflow using renewable energy. Solar panels power ventilation fans during peak heat periods when cooling is most needed. Battery backup systems ensure continued operation during cloudy periods or equipment maintenance.

Water recycling systems reduce operating costs in water-scarce desert regions while supporting cooling operations. Captured rainwater, condensate recovery, and greywater treatment provide sustainable water sources for cooling systems and irrigation.

The economic benefits of integrated passive cooling extend beyond energy savings. Reduced mechanical equipment requirements lower maintenance costs, improve system reliability, and reduce the technical expertise required for operation. These factors make passive cooling particularly attractive for remote locations or developing regions.

Conclusion

Hot climate greenhouse success depends on strategic design prioritizing natural ventilation, appropriate materials, and energy-efficient cooling systems. Combining passive and active strategies creates productive desert oases while controlling operational costs.