You see your crops wilting under the intense sun. Your energy bills are climbing higher every month. Trying to grow high-value produce in a hot climate feels like an uphill battle.

A well-designed hot climate greenhouse creates a controlled environment that boosts crop yields and quality by integrating specific structural designs, advanced materials, and synergistic cooling systems. This approach can lower operational costs and make year-round cultivation a profitable reality, even in the hottest regions.

I have spent over 29 years with CFGET, designing and implementing greenhouse solutions across the globe. I’ve seen firsthand how growers in Southeast Asia, Central Asia, and even parts of Europe struggle with extreme heat. The key isn’t just to fight the heat, but to work with it intelligently. A hot climate greenhouse is not simply a structure; it’s a complete ecosystem engineered for performance. This guide contains the essential knowledge I’ve gathered to help growers like you succeed where others have failed.

Why are greenhouses needed even in hot regions? What are the challenges?

Your open-field crops are exposed and vulnerable. Extreme heat, intense sunlight, and pests can wipe out your entire investment in a single season, leaving you with nothing to show for your hard work.

Greenhouses in hot regions are essential to shield crops from damaging solar radiation, control extreme temperatures, manage humidity, and protect against pests. The main challenges are preventing heat buildup, ensuring adequate ventilation, managing high energy costs for cooling, and selecting materials that withstand intense UV exposure.

Many people think greenhouses are only for making cold places warmer. This is a common and costly mistake. The real power of a greenhouse is environmental control. In a hot climate, this means creating a cooler, more stable environment than what exists outside. I remember a client in the Middle East who lost nearly half his cucumber crop to heat stress and sunscald. After we installed a properly designed greenhouse, his yields not only recovered but increased by 70% because he could now grow through the hottest months of the year. The greenhouse provided a shield against the harsh external conditions. It allowed him to precisely manage temperature, humidity, and light, turning an unpredictable environment into a predictable and profitable production system. This control is impossible to achieve in an open field, where you are completely at the mercy of the weather.

The Primary Challenges of Hot Climate Agriculture

Growing in hot climates presents a unique set of obstacles that can severely limit agricultural productivity. Understanding these specific issues is the first step toward designing an effective solution.

- Excessive Solar Radiation: In many hot regions, the intensity of sunlight is too high for most commercial crops. This leads to a condition called photoinhibition, where the plant’s photosynthetic machinery is damaged, stunting growth. It also causes physical damage like leaf burn and fruit scalding, which makes the produce unmarketable.

- Extreme Heat Buildup: An enclosed structure can quickly turn into an oven. Without proper management, the temperature inside a greenhouse can easily soar 15-20°C above the outside temperature, creating lethal conditions for plants. This is the single biggest challenge to overcome.

- Humidity Management: Hot climates are often either extremely humid or extremely arid. In humid regions like Southeast Asia, high humidity promotes fungal diseases like downy mildew and botrytis. In arid regions, low humidity causes plants to lose water too quickly through transpiration, leading to wilting and water stress.

- Pest and Disease Pressure: Warm temperatures accelerate the life cycles of many insect pests and pathogens. Open-field farming in these climates often requires heavy pesticide use. A greenhouse provides a physical barrier, which is a key component of an Integrated Pest Management (IPM) strategy.

| Challenge | Impact on Plant Health | Economic Consequence |

|---|---|---|

| Heat Stress | Reduced photosynthesis, flower drop, poor fruit set | Lower yields, crop failure |

| High Humidity | Increased fungal and bacterial diseases | Reduced marketable quality, crop loss |

| Intense Sunlight | Leaf scorch, fruit sunscald, stunted growth | Lower quality produce, reduced market value |

| Water Scarcity | Wilting, nutrient uptake issues, plant death | High irrigation costs, unsustainable water use |

Core Cooling Strategies: How do Ventilation, Shading, and Active Cooling Systems Work Together?

You install a fan, but it just blows hot air around. You put up a shade cloth, but now your plants aren’t getting enough light. Using single cooling methods in isolation is inefficient and often ineffective.

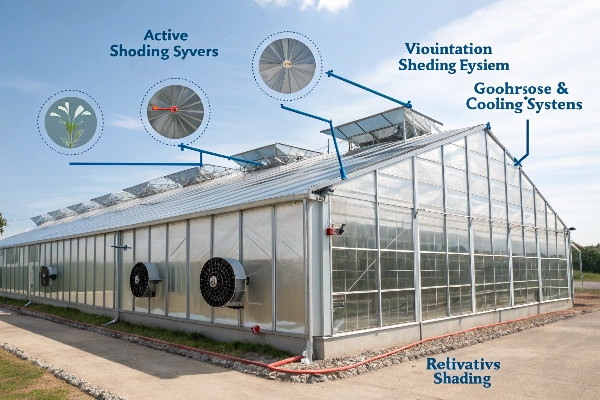

The most effective cooling strategy combines natural ventilation, dynamic shading, and active cooling into one integrated system. Each component supports the others, creating a multi-layered defense against heat that is both more effective and more energy-efficient than any single method.

The secret to cost-effective cooling is synergy. I learned this on a project in Central Asia where the summer temperatures are extreme. The client initially relied only on a powerful fan-and-pad system, and their energy bills were astronomical. We redesigned the greenhouse to first maximize natural ventilation through its structure. Then, we added an external, automated shading system. The active cooling system was then only needed during the absolute peak hours of the day. By making the systems work together, we cut their cooling energy consumption by over 60%. The systems didn’t just run at the same time; they were programmed to work in stages, creating a cascade of cooling effects.

1. Natural Ventilation: The First Line of Defense

Natural ventilation is the foundation of any energy-efficient cooling design. It uses the natural principles of thermal buoyancy (hot air rises) and wind pressure to exchange the air inside the greenhouse with cooler, fresher air from outside. For this to work effectively, the structural design is critical. We design greenhouses with a very high shoulder height, often around 6 meters. This creates a large buffer volume of air above the crops. The hottest air rises and collects high up in the peak of the roof, far away from the plants. We then install large roof vents and side vents. The total area of these vents should be at least 15-20% of the greenhouse floor area to ensure a high rate of air exchange, ideally 40 to 60 air changes per hour. This constant, passive airflow can reduce the internal temperature by several degrees without using any electricity.

2. Strategic Shading: Managing Solar Gain

The biggest source of heat in a greenhouse is direct sunlight. A shading system is essential for blocking a portion of this solar energy before it can heat up the interior. However, plants still need light for photosynthesis. The solution is dynamic shading. We use automated systems with sensors that measure the light intensity.

- External Shading: This is the most effective type. An aluminum shade screen or net is mounted above the greenhouse roof. It reflects the sun’s rays before they even hit the greenhouse covering, preventing that energy from entering the structure. This is far more efficient than internal shading, which traps heat inside.

- Internal Shading: These are useful for fine-tuning light levels and can also serve as an energy curtain at night to trap heat. However, they are a secondary tool for cooling.

The choice of shade material is also important. A 50% shade cloth, for example, will block 50% of the light. We select the percentage based on the specific light requirements of the crop and the intensity of the local sun.

3. Active Cooling: For Precision Control

When natural ventilation and shading are not enough to maintain the target temperature, an active cooling system kicks in.

- Evaporative Cooling (Pad-and-Fan): This is the most common and energy-efficient method for hot, dry climates. Large fans at one end of the greenhouse pull air through wet pads at the other end. As the water evaporates, it dramatically cools the air entering the greenhouse.

- High-Pressure Fogging/Misting: This system creates a very fine mist of water droplets inside the greenhouse. The droplets evaporate in the air, a process which absorbs a great deal of heat energy. This cools the air and also raises humidity, which can be beneficial for certain crops in arid regions.

- Semi-Closed Systems: For very high-value crops or extreme climates, we design semi-closed greenhouse systems. In this design, we create a special corridor or separate area where air is cooled intensively using refrigeration or other advanced methods. This cooled air is then distributed evenly throughout the growing area via ventilation ducts or tubes. This method offers the most precise control but is also the most expensive to build. It is a targeted solution that saves energy compared to trying to refrigerate the entire massive volume of a tall greenhouse, and it delivers superior results.

Greenhouse Material Choices: Pros and Cons of PC Sheets, Glass, Shade Nets & Aluminum Curtains

You choose a covering material based on price, only to find it degrades and turns yellow after two years. Or you invest in the most expensive option, but it traps too much heat, making your cooling problems worse.

The ideal greenhouse covering material for a hot climate balances durability, light transmission, and thermal insulation. Polycarbonate (PC) sheets offer great insulation, glass provides maximum light, and dynamic curtains give you flexible control over the environment.

The choice of covering material is one of the most permanent decisions you will make. It directly impacts every other system in your greenhouse. I have seen projects succeed or fail based on this choice alone. For example, a grower in Southeast Asia chose a standard, low-cost plastic film. In the high humidity and intense UV, it became brittle and tore within 18 months. We replaced it with a UV-stabilized, multi-wall polycarbonate sheet. Not only did the new material last, but its insulating properties also reduced the daytime heat load, lowering the run time of their cooling fans and saving them money every single day. The initial investment was higher, but the long-term return was undeniable.

Polycarbonate (PC) Sheets

Polycarbonate is often the best all-around choice for hot climates. Its main advantage is its structure. Multi-wall polycarbonate sheets have internal channels, creating air pockets. This gives them excellent thermal insulation properties, much like a double-paned window. This insulation works both ways: it slows down heat from getting in during the day and keeps warmth from escaping at night.

- Pros: Excellent thermal insulation, high impact resistance (it won’t shatter from hail), lightweight, and flexible.

- Cons: Can be scratched, and light transmission is slightly lower than glass.

- Crucial Factor: You must choose a product with a high-quality, co-extruded UV-resistant layer. Without this protection, the sun’s UV rays will break down the plastic, causing it to turn yellow and become brittle. A quality PC sheet should come with a 10-year warranty against yellowing and loss of light transmission.

Glass

Glass offers the highest level of light transmission, which can be a major advantage for light-loving crops. It is also extremely durable and does not degrade from UV exposure.

- Pros: Maximum light transmission (over 90%), very long lifespan, easy to clean, and does not degrade.

- Cons: Poor thermal insulation (as a single pane), heavy (requiring a stronger, more expensive structure), and can shatter.

- Hot Climate Consideration: For a hot climate, using single-pane glass is generally not recommended unless paired with a very effective shading system. Double-pane glass offers much better insulation but significantly increases the cost and weight. It’s a premium option for research institutions or growers of very high-value crops where maximizing light is the absolute top priority.

Shade Nets & Aluminum Curtains

These are not primary coverings but are essential components of a modern greenhouse system. They allow you to dynamically manage the environment.

- Aluminum Curtains (Reflective Screens): These are highly effective for hot climates. The shiny aluminum surface reflects a large portion of solar radiation back out of the greenhouse before it can turn into heat. They are often used as external shading systems for this reason. They also double as an energy-saving curtain at night.

- Shade Nets: These are woven or knitted fabrics designed to reduce light intensity by a specific percentage (e.g., 30%, 50%, 70%). They are a more cost-effective way to provide shade but are less effective at reflecting heat compared to aluminum screens. They are essential for protecting sensitive plants during the hottest parts of the day or for hardening off young plants.

| Material | Key Advantage | Best For | Main Drawback |

|---|---|---|---|

| Multi-wall PC Sheet | Balanced insulation & durability | General purpose, hot/arid climates | Requires quality UV coating |

| Glass (Single Pane) | Maximum light transmission | Research, high-light crops | Poor insulation, heavy |

| Aluminum Curtain | Heat reflection & flexibility | External shading, energy saving | Higher cost than nets |

| Shade Net | Cost-effective light reduction | Basic shading, plant protection | Less heat reflection |

How to Optimize Cooling Effects in Hot Climate Greenhouses through Structural Design and Layout?

You build a standard greenhouse, but it has hot spots and poor airflow. Your cooling systems run constantly but can’t keep up, because the basic design of the structure is fighting against them.

Optimizing the greenhouse structure itself is a passive cooling strategy that can dramatically reduce the workload on active systems. This involves orienting the building correctly, increasing its height, and designing for unimpeded airflow, which can cut cooling costs by up to 40%.

Structural design is the foundation of an efficient greenhouse. It’s something you have to get right from the very beginning. I once consulted on a large farm in a hot, arid region that had ten identical greenhouses built in a row. The five on the west side consistently underperformed. The reason was simple: the first five greenhouses were blocking the prevailing evening breeze, starving the others of natural ventilation. It was a layout problem. By simply changing the layout for their next expansion phase and increasing the roof height, we were able to rely almost entirely on natural ventilation for cooling, except on the most extreme days. The structure itself was doing most of the work, for free.

Orientation and Layout

The way you position your greenhouse has a huge impact on how much heat it absorbs.

- East-West Orientation: In most hot climates (away from the equator), the greenhouse should be oriented with its long axis running from east to west. This means the large roof surfaces face north and south. This exposes the smaller end-walls to the intense, low-angle sun in the morning and afternoon, reducing the total solar gain during the hottest parts of the day.

- Spacing: When building multiple greenhouses, there must be enough space between them. A good rule of thumb is to have a distance of at least one to two times the height of the greenhouse. This ensures that one structure does not block airflow to the next and prevents the buildup of "heat islands" between the buildings.

The Importance of Height

As I mentioned earlier, height is one of the most powerful and simple tools for passive cooling. A tall greenhouse with a shoulder height of 6 meters or more functions like a chimney.

- Sunlight warms the plants and the floor.

- This heat is transferred to the air, causing it to rise.

- In a tall greenhouse, this hot air collects high above the crop canopy, in the peak of the roof.

- Large vents at the very top of the roof allow this hot air to escape.

- This escape of hot air creates negative pressure, which pulls cooler, fresh air in through the side vents located lower down.

This natural convection process, or "chimney effect," provides constant, free ventilation. A short greenhouse does not have enough vertical space for this effect to work properly, and the hot air gets trapped at plant level.

Designing for Airflow

Every element of the structure should be designed to promote, not block, airflow.

- Vent Design: Vents should be large and unobstructed. Roll-up sides are excellent for providing massive amounts of ventilation at plant level. Roof vents should be continuous along the peak for maximum hot air exhaust.

- Internal Layout: Rows of crops should be aligned with the direction of airflow (from the cooling pads to the fans, or from the side vents to the roof vents). This ensures that the cool air can move freely through the plant canopy.

- Structural Beams: The internal structure (trusses and purlins) should be designed to be as open as possible to avoid trapping pockets of hot air.

By focusing on these structural elements first, you create a greenhouse that is inherently easier and cheaper to cool. You are working with nature, not against it.

Conclusion

Success in hot climates demands more than just a standard greenhouse. It requires an integrated system where the structure, materials, and cooling strategies work together to create an optimal, energy-efficient growing environment.