Winter temperatures create constant challenges for greenhouse growers worldwide. Cold weather drastically reduces growing success, kills sensitive plants, and increases heating costs to unsustainable levels without proper insulation strategies.

Effective greenhouse insulation combines structural elements with operational techniques to create thermal barriers that maintain optimal growing temperatures while minimizing energy costs. The 16 methods described in this guide work through heat retention, loss prevention, and supplemental warming systems.

When I first started designing greenhouse systems for CFGET 15 years ago, I quickly discovered that insulation knowledge makes the difference between success and failure for winter operations. Many growers believe heating systems alone solve winter growing challenges, but this approach proves financially unsustainable without proper insulation. Through working with countless growers across diverse climate zones—from the harsh winters of Central Asia to the milder but still challenging European conditions—I’ve compiled practical insulation methods that actually work in real-world applications.

Don’t Miss:——Exploring Greenhouse Types: Finding the Perfect Structure for Your Needs

You might like:——Mastering Strawberry Greenhouse Cultivation: Best Practices for Optimal Growth?

Understanding Greenhouse Heat Loss and Counter Strategies

Many greenhouse operators struggle with excessive energy bills during winter months. Heat constantly escapes through numerous pathways, creating uncomfortable growing conditions and financial strain for operators.

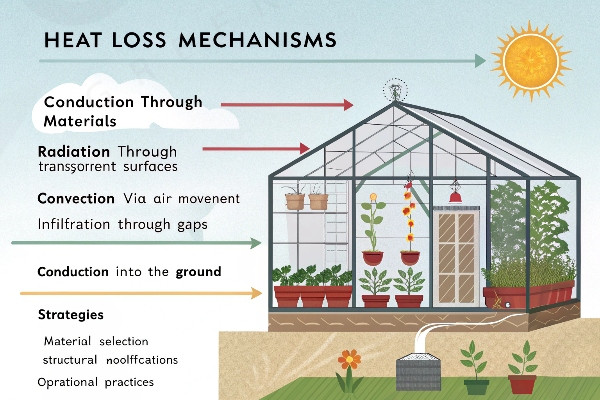

Greenhouse heat loss occurs through five main mechanisms: conduction through materials, radiation through transparent surfaces, convection via air movement, infiltration through gaps, and conduction into the ground. Each requires specific counter-strategies involving material selection, structural modifications, and operational practices.

Before implementing any insulation solution, understanding exactly how and where heat escapes from your greenhouse provides the foundation for effective countermeasures. During my consultation work with a large vegetable producer in Kazakhstan, we conducted a comprehensive heat loss audit that revealed surprising results—their greatest heat loss wasn’t through the covering as they assumed, but through structural gaps and ground contact.

Heat loss mechanism #1: Conduction involves direct heat transfer through materials. The thermal conductivity of greenhouse covering materials significantly impacts overall heat retention. Glass, while excellent for light transmission, conducts heat rapidly compared to modern polycarbonate panels. Many of our clients have reduced heating costs by 15-20% simply by upgrading from single-layer to twin-wall polycarbonate panels.

Heat loss mechanism #2: Radiation represents heat energy emitted from warmer surfaces to cooler ones. During cold nights, the warm interior surfaces of your greenhouse radiate heat outward toward the cold sky. This explains why cloudy winter nights typically result in less greenhouse cooling than clear nights—clouds reflect some radiated heat back downward. Thermal barriers like infrared (IR) films and energy curtains specifically address this loss mechanism.

Heat loss mechanism #3: Convection occurs when warm air circulates and contacts cooler surfaces, transferring heat away. This becomes particularly problematic along the greenhouse perimeter and near any single-layer covering. When we installed thermal imaging systems for a client in Northern Europe, convective heat loss patterns became immediately visible along structural elements like rafters and purlins where warm air contacted cold surfaces.

Heat loss mechanism #4: Infiltration represents direct air exchange through gaps, cracks, and openings. Even tiny openings can create significant cumulative heat loss. During a facility assessment in Russia, we discovered that poorly sealed vents and door gaps contributed almost 30% of their total winter heat loss. Simple weatherstripping and gasket repairs reduced their heating costs substantially.

Heat loss mechanism #5: Ground conduction pulls heat directly from your greenhouse floor into the cooler soil below. This often-overlooked pathway can account for 10-15% of total heat loss in ground-contact greenhouses. Perimeter insulation extending 2-3 feet below grade level creates an effective thermal break between interior spaces and the surrounding soil mass.

Once you understand these fundamental mechanisms, implementing appropriate countermeasures becomes much more targeted and effective. Through my work with CFGET across diverse climate regions, I’ve found that most greenhouse operators benefit most from addressing all five pathways rather than focusing exclusively on one area. The comprehensive approach delivers synergistic benefits that single-focus strategies miss.

Economical Insulation Tips for Small Home Greenhouses

Home greenhouse owners often abandon winter growing due to perceived high heating costs. Limited budgets and simple structures seem incompatible with cold-weather production, causing seasonal shutdowns that waste valuable growing space.

Small greenhouse owners can implement affordable insulation using bubble wrap insulation, thermal mass storage, perimeter sealing, insulated foundation walls, and overnight plant covers. These methods require minimal investment while delivering significant temperature maintenance benefits during winter months.

During my early career with CFGET, I worked extensively with small-scale growers who needed cost-effective solutions rather than commercial-grade systems. These economical approaches have proven repeatedly successful across various climates and structures. Let me share the most practical methods for home greenhouse owners working with limited budgets.

Method #1: Bubble wrap insulation provides remarkable effectiveness for its low cost. Not standard packaging bubble wrap but horticultural bubble wrap with larger bubbles and UV treatment offers both insulation and light transmission. I recommend securing it to the interior greenhouse frame using greenhouse clips rather than tape, which deteriorates quickly in high humidity environments. For a client in Central Europe with a small hobby greenhouse, this simple addition increased minimum overnight temperatures by 4-5°C without any additional heating.

Method #2: Water barrel thermal mass storage utilizes water’s excellent heat capacity to stabilize temperatures. Position dark-colored water barrels (55-gallon drums work well) along the north wall where they absorb heat during daylight hours and release it overnight. This passive approach costs almost nothing if you source used food-grade containers. One small herb grower I worked with in Romania managed to maintain temperatures 7°C above outdoor conditions using just this method combined with basic perimeter insulation.

Method #3: Complete perimeter sealing addresses infiltration losses that plague many small greenhouses. Use weatherstripping foam tape around doors and vents, silicone sealant for fixed joints, and brush-style door sweeps for entryways. This inexpensive approach delivers outsized results by eliminating drafts. During energy assessments for small greenhouse owners, I typically find that comprehensive sealing reduces overnight heat loss by 15-25% with material costs under $50.

Method #4: Insulated foundation perimeters prevent ground-level heat loss. Extruded polystyrene foam board (2-inch thickness) installed vertically around the greenhouse foundation creates an effective thermal break. Extend this insulation at least 18 inches below grade for maximum effectiveness. When retrofitting an existing greenhouse, you can install this as an exterior skirt without major excavation. For a client’s small greenhouse in northern China, this modification alone raised soil temperatures by 3-4°C during winter months.

Method #5: Overnight plant covers within the greenhouse create micro-environments for sensitive plants. Row covers, horticultural fleece, or even plastic sheeting supported slightly above plant canopies trap air and create temperature differentials of 2-3°C. This targeted approach allows you to prioritize protection for your most valuable or sensitive plants without heating the entire structure. I recommend using lightweight PVC hoops to support these covers without damaging plants.

Method #6: Secondary glazing layers create dead air spaces that dramatically improve insulation. For glass greenhouses, adding an interior layer of greenhouse-grade polyethylene film with a small air gap (2-3 cm) can reduce heat loss through the covering by 30-40%. While installing this requires some initial investment, the materials cost remains reasonable for small structures. A home greenhouse owner in Moldova implemented this system with our guidance and reported a 35% reduction in overnight temperature drop.

Efficient Heating System Choices for Medium to Large Commercial Greenhouses

Commercial growers face significant production losses without proper winter climate control. Complex heating requirements across large growing areas create substantial energy costs that directly impact profit margins.

Medium to large commercial greenhouses benefit from integrated heating approaches including thermal curtain systems, perimeter insulation boards, anti-condensation films, heat distribution tubes, and strategically zoned heating controls. These systems deliver targeted heat while minimizing energy expenditure.

Through my work designing climate control systems for large-scale operations with CFGET, I’ve observed firsthand the enormous impact proper insulation and heating systems have on operational profitability. Commercial operations require more sophisticated approaches than hobby greenhouses, but the principles remain consistent—minimize loss, maximize retention, and heat efficiently.

Method #7: Automated thermal curtain systems represent one of the most effective insulation investments for commercial operations. These systems deploy horizontal insulating layers that create a barrier between the growing zone and the greenhouse roof during nighttime hours. Modern thermal curtains with aluminum strips woven into polyester fabric can reduce nighttime heat loss by 35-60% depending on material quality. For a 2-hectare tomato producer in Eastern Europe, our installed curtain system reduced heating costs by 43% with a payback period of just under two years.

Method #8: Under-bench heating systems concentrate warmth in the plant root zone rather than heating the entire air volume. Hot water pipes or electric heating cables installed beneath growing benches create micro-climate zones where plants develop. This targeted approach allows you to maintain lower overall air temperatures while still providing optimal growing conditions. When we implemented this system for a commercial flower grower in Central Asia, they reduced their overall energy consumption by 27% while improving crop quality.

Method #9: Double-layer inflated polyethylene roofing creates an insulating air pocket between two plastic films. A small blower maintains constant air pressure between these layers, creating a surprisingly effective thermal barrier. This system offers both low installation cost and excellent insulation properties, with typical heat retention improvements of 30-40% compared to single-layer coverings. For regions without extreme snow loads, this represents one of the most cost-effective commercial insulation approaches.

Method #10: Perimeter wall insulation using rigid foam board dramatically reduces edge losses. Commercial greenhouses lose significant heat through their sidewalls—particularly along the foundation and knee wall areas. Installing exterior foam insulation boards (minimum 2-inch thickness) on these surfaces delivers substantial energy savings. One commercial vegetable producer in Northern China reduced their heating costs by 18% after implementing our recommended perimeter insulation system.

Method #11: Anti-condensation films prevent water droplet formation on interior surfaces. Condensation not only blocks light transmission but creates cold water droplets that fall onto plants and substrate, chilling the growing environment. Modern greenhouse films with anti-condensation additives maintain higher light transmission while reducing this cooling effect. When we replaced standard polyethylene with anti-condensation film for a client in humid Southeast Asia, they reported improved winter plant health despite using the same heating system.

Method #12: Heat distribution tubes ensure even temperature throughout large growing areas. Perforated polyethylene tubes connected to heating systems deliver warm air directly at plant level, eliminating cold spots and stratification. This horizontal distribution approach maintains consistent growing conditions while using less total energy. A commercial operation I consulted for in Kazakhstan implemented this system throughout their 1.5-hectare greenhouse and eliminated the 5-7°C temperature differential they previously struggled with.

Heating Your Greenhouse Without Electricity: Natural Warming and Passive Solar Applications

Remote greenhouse operations often lack reliable electricity access for conventional heating. Off-grid situations and power outage vulnerabilities create significant risks for winter growing without alternative heating approaches.

Non-electric greenhouse heating relies on solar gain optimization, thermal mass storage, compost heat systems, passive geothermal designs, and strategic structural orientation. These methods harness natural energy sources to maintain viable growing temperatures without electrical dependence.

My most challenging yet rewarding projects with CFGET have involved designing heating solutions for locations without reliable electricity. Through these experiences, I’ve developed practical approaches that combine ancient wisdom with modern materials to create surprisingly effective non-electric heating systems.

Method #13: Optimized solar greenhouse orientation maximizes natural heat gain. Positioning your greenhouse with its long axis running east-west allows maximum southern exposure (northern exposure in Southern Hemisphere) during limited winter daylight. The north wall should be well-insulated and potentially even opaque to reflect light while preventing heat loss. When helping a client design a new passive solar greenhouse in a remote mountain region of Central Asia, this fundamental orientation principle improved their winter heat gain by approximately 25% compared to their previous conventionally-oriented structure.

Method #14: Underground heat storage systems utilize earth’s thermal mass for temperature stabilization. Burying perforated drainage pipes 4-6 feet below the greenhouse floor and connecting them to a solar collector box creates a passive heat exchange system. Warm daytime air circulates through these tubes, heating the surrounding soil mass which then releases heat overnight. For a non-electric herb production facility I designed in a remote area, this system maintained temperatures 8-10°C above ambient during winter nights.

Method #15: Hot compost heating systems generate biological heat through decomposition processes. Properly constructed compost piles reaching thermophilic temperatures (60-70°C) can provide significant heat when incorporated into greenhouse design. Using insulated compost chambers with water heat exchange circuits delivers controllable heat without electricity. A small off-grid vegetable producer implemented this system based on our design specifications and successfully maintained minimum temperatures of 10°C throughout winter while simultaneously producing compost for their growing operation.

Method #16: Passive water wall thermal mass consists of water-filled containers positioned along the north wall to absorb daytime solar radiation. Black-painted containers maximize absorption while insulated reflective backing prevents heat loss to the exterior. This simple approach requires no moving parts yet effectively stabilizes temperatures. During a project with subsistence farmers in a remote mountain region, installing a water wall system with locally available materials improved their minimum overnight temperatures by 6-8°C without any operational costs.

When designing passive heating systems, I always emphasize the importance of combining multiple complementary approaches rather than relying on a single method. Each technique addresses different aspects of the heating challenge, and their combined effect exceeds the sum of individual contributions. For example, a properly oriented greenhouse with both thermal mass components and good perimeter insulation typically performs 30-40% better than predicted by calculating each element separately.

I also recommend incorporating simple manual management practices into passive heating strategies. Actions like deploying interior curtains before sunset, closing vents early to trap afternoon heat, and timing irrigation to avoid evaporative cooling during cold periods significantly enhance passive system performance. These operational disciplines cost nothing yet dramatically improve results.

Conclusion

Effective greenhouse winter insulation combines understanding heat loss mechanisms with implementing appropriate counterstrategies for your specific situation. Whether using economical DIY methods for home greenhouses or sophisticated systems for commercial operations, these 16 practical techniques provide reliable winter growing conditions while minimizing energy costs.