Choosing the wrong glass thickness can lead to catastrophic structural failure and total crop loss. Your glass must withstand wind, snow, and thermal stress while protecting valuable plants.

Greenhouse roof glass typically requires 4-6mm thickness for single glazing or 4mm+4mm for insulated units. Side walls use 4-5mm thickness, with thicker glass needed for larger spans and severe weather conditions.

During my nearly three decades in greenhouse construction, I have witnessed how glass thickness requirements evolved alongside structural engineering advances and safety regulations. The early Chinese greenhouse boom relied on basic 4-5mm single-layer tempered glass that provided adequate protection for simple applications. Today’s sophisticated cultivation requirements and safety standards demand more careful thickness selection based on structural loads, environmental conditions, and specific applications.

What Thickness is Generally Used for Greenhouse Roof Glass?

Roof glass bears the heaviest loads and faces the harshest conditions in your greenhouse. Inadequate thickness leads to catastrophic failure during storms or snow events.

Standard greenhouse roof glazing uses 4-6mm tempered glass for single-layer systems, while insulated units typically employ 4mm+4mm configurations. Larger spans and severe weather zones require 6mm or thicker glass for adequate safety margins.

Roof glazing experiences multiple simultaneous loads that determine minimum thickness requirements. Dead loads from the glass weight itself create constant downward pressure on support structures. Live loads from maintenance activities, equipment installations, and accumulated debris add variable forces. Snow loads in cold climates can exceed 150 kg/m² in extreme conditions. Wind loads create both positive pressure pushing down and negative pressure trying to lift glass panels from their frames.

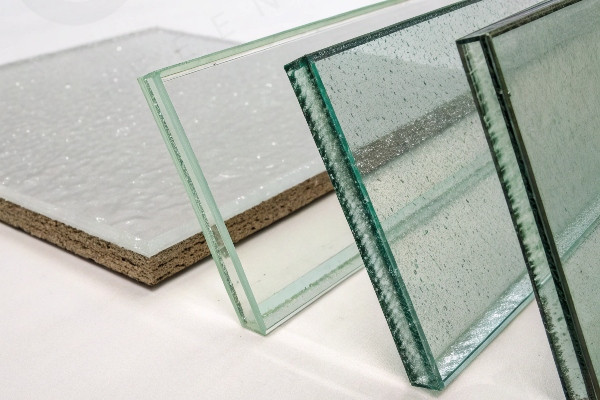

The relationship between glass thickness and load-bearing capacity follows engineering principles that account for material properties and safety factors. Tempered glass provides approximately four times the strength of standard annealed glass, allowing thinner sections for equivalent load capacity. However, tempered glass cannot be cut or modified after manufacturing, requiring precise sizing during production. Laminated glass offers impact resistance and safety benefits but requires different thickness calculations.

I worked with a vegetable grower in northern Germany who experienced roof glass failures during a severe winter storm. His original 4mm single-layer system could not handle combined wind and snow loads that exceeded design limits. Three panels shattered, allowing freezing air and precipitation to damage crops worth over €15,000. We redesigned the roof system using 6mm tempered glass with reduced panel sizes and additional support structures. The strengthened system has survived multiple severe weather events without damage over the past six years.

Panel size directly affects required glass thickness through span-to-thickness ratios established by structural engineering codes. Larger panels need thicker glass to maintain adequate strength and deflection limits. Standard greenhouse panels measuring 1.2m x 2.0m typically use 4-5mm thickness. Panels exceeding 1.5m x 2.5m may require 6mm or thicker glass depending on support conditions and local load requirements.

Thermal stress considerations become important in roof applications where glass experiences direct solar heating and rapid cooling. Thicker glass has higher thermal mass and different expansion characteristics than thin glass. Proper glazing details must accommodate thermal movement while maintaining weatherproof seals. Tempered glass handles thermal stress better than annealed glass but still requires careful design attention.

Manufacturing tolerances affect actual glass thickness and performance characteristics. Standard float glass typically varies ±0.2mm from nominal thickness, while high-quality horticultural glass maintains tighter tolerances of ±0.1mm. These variations can affect structural calculations and glazing system fit. Professional greenhouse suppliers specify glass with appropriate tolerances for each application.

Support structure design must complement glass thickness selection to ensure proper load distribution and structural integrity. Closer support spacing allows thinner glass while wider spans require thicker sections. Glazing bar design affects local stress concentrations around glass edges. Proper engineering ensures that glass thickness, panel size, and support spacing work together effectively.

| Roof Application | Glass Thickness | Panel Size | Load Capacity | Typical Use |

|---|---|---|---|---|

| Light Duty | 4mm tempered | 1.0m x 1.5m | Basic loads | Hobby greenhouses |

| Standard Duty | 5mm tempered | 1.2m x 2.0m | Normal loads | Commercial growing |

| Heavy Duty | 6mm tempered | 1.5m x 2.5m | High loads | Severe weather zones |

| Extreme Duty | 8mm tempered | 1.0m x 2.0m | Maximum loads | Hurricane/snow regions |

What is the Recommended Thickness for Greenhouse Side Wall Glass?

Side wall glass faces different challenges than roof glazing but still requires careful thickness selection for safety and performance. Wind pressure and impact resistance become primary concerns.

Greenhouse side walls typically use 4-5mm tempered glass for standard applications, with 6mm thickness recommended for areas prone to severe weather or potential impact damage from equipment or personnel.

Side wall glazing experiences primarily horizontal loads from wind pressure rather than the vertical loads that dominate roof design. Wind creates positive pressure on windward walls and negative pressure on leeward walls that can be equally challenging structurally. The pressure distribution varies with building height, with maximum loads typically occurring at upper elevations where wind speeds are highest.

Impact resistance becomes more important for side wall glazing due to proximity to equipment, vehicles, and personnel activities. Maintenance equipment, delivery trucks, and daily operations create potential impact hazards that roof glazing rarely encounters. Tempered glass provides excellent impact resistance, but thickness still affects the energy absorption capacity and safety performance.

I remember working with a flower grower in the Netherlands who experienced repeated side wall glass breakage from forklift operations during busy shipping periods. His original 4mm glazing system was adequate for wind loads but could not withstand occasional impacts from equipment. We upgraded the lower wall sections to 6mm tempered glass while maintaining 4mm thickness in upper areas where impact risk was minimal. This targeted approach eliminated breakage problems while controlling upgrade costs.

Height considerations affect side wall glass selection through varying wind pressure distributions and accessibility requirements. Lower wall sections experience higher impact risk but lower wind loads. Upper sections face maximum wind pressure but minimal impact exposure. Some installations use graduated thickness with thicker glass in high-risk zones and standard thickness elsewhere.

Ventilation openings in side walls create stress concentrations around cutouts that may require thicker glass or special reinforcement. Hinged vents, louvre systems, and exhaust fans all create structural discontinuities that affect load distribution. Proper engineering accounts for these factors in thickness selection and support design.

Thermal considerations for side walls differ from roof applications due to orientation and shading effects. East and west walls experience intense morning and afternoon solar heating that creates thermal stress. North walls in northern climates may experience minimal solar gain but significant heat loss. South walls typically receive moderate, consistent solar exposure. These thermal patterns influence glass selection and glazing details.

Foundation and lower wall connections require special attention to prevent moisture infiltration and thermal bridging. Glass panels must seal properly against foundation walls while accommodating building settlement and thermal movement. Proper flashing and sealant systems protect against water damage that can compromise structural integrity over time.

Safety considerations for side wall glazing include both structural failure and injury prevention. Tempered glass breaks into small, relatively harmless pieces compared to large, sharp shards from annealed glass. However, thickness still affects the likelihood of breakage under impact or thermal stress. Building codes may specify minimum thickness requirements for glazing in accessible locations.

| Wall Location | Recommended Thickness | Primary Loads | Safety Factors | Typical Applications |

|---|---|---|---|---|

| Lower Walls | 5-6mm tempered | Impact, equipment | High safety | Work areas |

| Upper Walls | 4-5mm tempered | Wind pressure | Standard safety | General glazing |

| Vent Areas | 5mm tempered | Concentrated loads | Medium safety | Ventilation systems |

| Entry Areas | 6mm tempered | Impact, traffic | Maximum safety | Doors, high traffic |

Is Glass Thickness Related to Greenhouse Structural Safety?

Glass thickness directly affects structural safety through load-bearing capacity, failure modes, and overall system integrity. Inadequate thickness creates catastrophic failure risks.

Glass thickness determines structural load capacity, with each millimeter increase providing approximately 40% more strength. Proper thickness selection prevents progressive failure that can collapse entire greenhouse sections during extreme weather events.

Structural safety in greenhouse design involves understanding how glass panels interact with support frames to create integrated systems that resist applied loads. Glass panels act as structural diaphragms that transfer loads between frame members while providing weather protection. Inadequate glass thickness can create weak links that compromise overall structural integrity during critical loading events.

Progressive failure represents one of the most dangerous structural scenarios in greenhouse design. When one glass panel fails due to inadequate thickness, its loads transfer to adjacent panels that may also be operating near capacity limits. This load redistribution can trigger a cascade of failures that rapidly propagates across large roof or wall areas. Proper thickness selection with adequate safety margins prevents this type of catastrophic failure.

I witnessed a devastating structural failure at a tomato facility in southern Italy where inadequate glass thickness contributed to progressive collapse during a severe windstorm. The original 4mm roof glazing was marginal for the local wind loads, and when several panels failed simultaneously, the load redistribution caused additional failures that ultimately damaged over 40% of the roof area. The crop loss exceeded €200,000, and the facility required complete reconstruction. The replacement system used 6mm glass with enhanced support structures that have performed flawlessly through subsequent storms.

Load path analysis reveals how glass thickness affects force distribution through greenhouse structures. Thicker glass can span longer distances between supports, allowing more economical frame designs with fewer structural members. Conversely, thinner glass requires closer support spacing that increases frame costs but may reduce glazing expenses. Optimal design balances these factors to achieve minimum total cost while maintaining safety.

Deflection limits establish another critical relationship between glass thickness and structural safety. Excessive glass deflection under load can damage seals, create water infiltration, and cause stress concentrations that lead to failure. Building codes typically limit glass deflection to span/60 or span/75 depending on the application. Thicker glass deflects less under equivalent loads, providing better long-term performance.

Dynamic loading from wind gusts, seismic events, or equipment vibration creates different stress patterns than static loads. Glass thickness affects the natural frequency and damping characteristics of glazing systems. Proper thickness selection helps avoid resonance conditions that can amplify dynamic loads and cause fatigue failures over time.

Thermal stress represents another safety consideration related to glass thickness. Thick glass has higher thermal mass and different expansion characteristics than thin glass. Rapid temperature changes can create significant stress differentials across glass thickness that may cause failure if not properly accommodated. Tempered glass handles thermal stress better than annealed glass, but thickness still affects thermal performance.

Safety factors in structural design account for uncertainties in loads, materials, and construction quality. Standard practice applies safety factors of 2.5-4.0 to ultimate glass strength depending on the application and consequences of failure. These factors ensure that normal thickness glass can handle extreme loads while providing reserve capacity for unexpected conditions.

| Safety Factor | Glass Thickness | Load Capacity | Failure Risk | Applications |

|---|---|---|---|---|

| Minimal (1.5x) | 4mm | Basic loads | Higher risk | Low-value crops |

| Standard (2.5x) | 5mm | Normal loads | Acceptable | Commercial growing |

| Conservative (3.5x) | 6mm | High loads | Low risk | High-value crops |

| Maximum (4.0x) | 8mm | Extreme loads | Minimal risk | Critical facilities |

How Does Budget Affect the Choice of Greenhouse Glass Thickness?

Budget constraints force difficult decisions between initial costs and long-term performance, but inadequate glass thickness often creates higher total costs through failures and replacements.

Thicker glass costs 15-25% more initially but provides 40-60% better load capacity and longer service life. Economic analysis typically shows that proper thickness selection pays for itself through reduced maintenance, insurance, and replacement costs.

Initial cost considerations often drive glass thickness decisions toward minimum acceptable values, but this approach frequently results in higher total ownership costs over the greenhouse lifespan. Thicker glass requires higher upfront investment but provides better structural performance, longer service life, and reduced maintenance requirements. Proper economic analysis must consider all cost factors over the expected system life rather than just initial purchase prices.

Material costs increase approximately linearly with glass thickness, meaning 6mm glass costs about 50% more than 4mm glass per square meter. However, structural performance increases more rapidly than thickness, providing better value at moderate thickness increases. The relationship between cost and performance creates optimal thickness ranges that balance initial investment against long-term benefits.

I worked with a budget-conscious grower in eastern Europe who initially specified 4mm glass throughout his facility to minimize construction costs. Within two years, he experienced multiple panel failures that required emergency repairs during critical growing seasons. The replacement costs, crop losses, and downtime exceeded the initial savings from thinner glass. We redesigned the facility using 5mm roof glass and 4mm side glass, which eliminated failure problems while adding only 8% to the total glazing cost.

Labor costs for glass installation remain relatively constant regardless of thickness, meaning the additional material cost for thicker glass represents the primary budget impact. Installation complexity may actually decrease with thicker glass due to better handling characteristics and reduced breakage risk during construction. Professional installers often prefer working with thicker glass that provides better durability margins.

Insurance implications of glass thickness selection can significantly affect long-term costs. Many insurance policies include coverage limits or deductibles that make glass thickness an important risk management consideration. Thicker glass reduces claim frequency and may qualify for premium discounts that offset higher initial costs over time.

Financing options may influence thickness decisions through their impact on cash flow and project economics. Longer-term financing can make thicker glass more affordable by spreading costs over extended periods. Energy efficiency incentives or agricultural development grants may also affect the economic analysis by reducing net costs for higher-performance systems.

Regional cost variations affect the economic analysis of glass thickness selection. Areas with high labor costs may favor thicker glass that reduces installation time and maintenance requirements. Regions with severe weather conditions may require thicker glass regardless of cost considerations due to structural safety requirements.

Value engineering approaches can optimize glass thickness selection by analyzing performance requirements for different greenhouse zones. Roof areas experiencing maximum loads may justify premium thickness while side walls in protected locations use standard thickness. This targeted approach balances performance and cost more effectively than uniform thickness selection.

Long-term cost modeling reveals that glass thickness decisions affect multiple cost categories over the greenhouse lifespan. Thicker glass typically provides lower maintenance costs, reduced insurance claims, better energy performance, and longer service life. These benefits often justify higher initial investment, especially for commercial operations where crop losses from glass failure create significant economic impacts.

| Thickness Option | Initial Cost | Annual Maintenance | Failure Risk | 10-Year Total Cost |

|---|---|---|---|---|

| 4mm Economy | $25/m² | $2.50/m² | 15% chance | $450/m² |

| 5mm Standard | $30/m² | $1.50/m² | 8% chance | $380/m² |

| 6mm Premium | $37/m² | $1.00/m² | 3% chance | $350/m² |

| 8mm Maximum | $50/m² | $0.50/m² | 1% chance | $375/m² |

Conclusion

Optimal greenhouse glass thickness balances structural safety, performance requirements, and budget constraints, with 5-6mm typically providing the best value for most commercial applications through superior load capacity and service life.