Excited about building a Chinese greenhouse but worried about the potential high costs? It’s a very common concern!

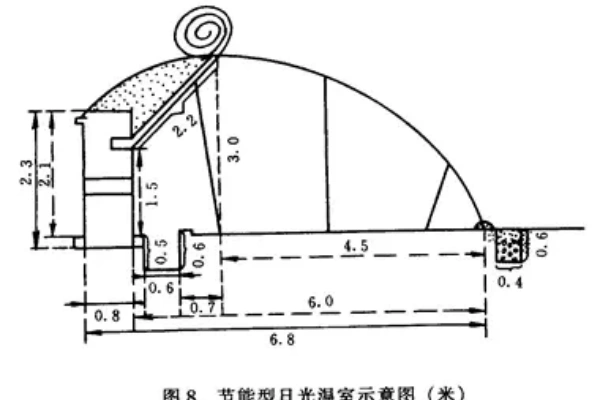

You can reduce construction costs by carefully choosing materials, optimizing the design to minimize waste, doing some of the work yourself (DIY), and purchasing materials in bulk. Smart planning is key! The construction cost of the Chinese-style solar greenhouse is 45 to 65 RMB per square meter, excluding civil engineering.

Let’s explore practical ways to make your project more affordable.

Material Selection: Affordable Alternatives?

Feeling overwhelmed by the prices of standard greenhouse materials? There are often cheaper options!

Choosing affordable alternatives for materials like the frame, covering, and insulation can significantly lower costs. Consider recycled materials, locally sourced options, and less expensive substitutes without sacrificing essential performance.

It’s not just about finding any cheap material. It’s about finding the right cheap material. Let’s explore some smart substitutions.

Smart Material Substitutions:

| Component | Standard Material | Affordable Alternative(s) | Considerations |

|---|---|---|---|

| Frame | New Steel | Recycled Steel, Bamboo, Strong Timber (treated for durability), PVC Pipe (for smaller structures) | Recycled Steel: Requires careful inspection for rust and damage. Bamboo: Needs proper treatment against pests and rot. Timber: Ensure it’s sourced sustainably and treated. PVC: Limited structural strength, best for smaller spans. |

| Covering | High-Grade Polycarbonate | Thicker Polyethylene Film (UV-treated), Recycled Greenhouse Plastic (if available), Glass(salvaged window) | Polyethylene Film: Shorter lifespan than polycarbonate, but much cheaper. Recycled Plastic: Check for tears and UV degradation. Glass: Heavier, requiring a stronger frame, and more prone to breakage, but excellent light transmission and longevity if handled carefully. |

| Insulation | Commercial Foam Boards | Straw Bales (tightly packed), Rice Hulls, Recycled Fabric/Clothing (densely packed), Reflective Foil over other materials, Earth (for berms and wall construction) | Straw/Rice Hulls: Must be kept dry to prevent rot and pest infestations. Recycled Fabric: Ensure it’s clean and free of contaminants. Earth: Excellent thermal mass, but requires significant labor and space. |

| North Wall | Concrete Block | Rammed Earth, Cob, Sandbags filled with earth, Recycled Brick | Rammed Earth/Cob: Labor-intensive, but very low-cost and sustainable. Requires specific soil composition. Sandbags: Easy to work with, but need to be stabilized. Recycled Brick: Check for structural integrity. |

I remember a friend who built a small Chinese greenhouse almost entirely from reclaimed materials. He used old barn wood for the frame, salvaged windows for the south-facing glazing, and straw bales for insulation. It was incredibly cost-effective, and it worked beautifully!

Design Optimization: Reducing Material Waste?

Concerned about wasting materials and driving up costs? Smart design can minimize this.

Optimizing the greenhouse design involves choosing a size and shape that efficiently uses materials, minimizing cuts and custom pieces, and standardizing dimensions to match readily available material sizes.

It’s like planning a sewing project – you want to arrange your pattern pieces on the fabric to minimize scraps. The same principle applies here.

Strategies for Design Optimization:

| Strategy | Description | Example |

|---|---|---|

| Standard Dimensions | Design the greenhouse to match standard lengths of lumber, plastic film, and other materials. | If lumber comes in 8-foot lengths, design the greenhouse width or length in multiples of 8 feet (e.g., 8, 16, 24 feet) to avoid cutting and wasting pieces. |

| Simple Shapes | Opt for simple rectangular or square shapes. Avoid complex angles or curves that require more cutting and fitting. | A basic rectangular greenhouse is easier and cheaper to build than one with a rounded roof or multiple angles. |

| Modular Design | If planning a large greenhouse, consider building it in modular sections. This allows for easier construction and expansion in the future, and can also help with material efficiency. | Instead of one long 60-foot greenhouse, build three 20-foot sections that can be joined together. This allows you to use standard material lengths more efficiently and potentially build in stages as your budget allows. |

| Minimize Cuts | Plan the layout of materials to minimize the number of cuts required. | When covering the roof with plastic film, choose a film width that matches the roof’s dimensions as closely as possible, reducing the need to cut and overlap the film. |

| Pre-fabrication (if possible) | Consider using pre-fabricated components, such as trusses or wall panels, if available and cost-effective. This can reduce on-site cutting and assembly time. | Pre-made trusses can be more efficient than building them from scratch, especially for larger greenhouses. |

| Consider the land | If you want to build a 9-meter wide × 40-meter long greenhouse, its cost may be 30,000 to 50,000 yuan, depending on the local infrastructure. | The prices clearly marked here are all in RMB. |

Think of it like playing with LEGOs. You want to use the standard blocks as much as possible, rather than constantly cutting and modifying them.

DIY: Saving on Labor Costs?

Worried about the expense of hiring contractors? Doing some of the work yourself can be a huge cost-saver.

Taking on some or all of the construction work yourself (DIY) can significantly reduce labor costs. Tasks like site preparation, foundation laying, frame assembly, and insulation installation are often manageable for those with basic construction skills.

However, it’s crucial to be realistic about your skills and the time commitment involved.

Assessing DIY Feasibility:

| Task | Description | Skill Level Required | Considerations |

|---|---|---|---|

| Site Preparation | Clearing the area, leveling the ground, removing vegetation. | Basic landscaping skills, physical labor. | Access to basic tools (shovel, rake, wheelbarrow). Time commitment can be significant depending on the site’s condition. |

| Foundation | Digging trenches, mixing and pouring concrete (if needed), laying a base of gravel or compacted earth. | Basic concrete/masonry skills (for concrete foundations), understanding of leveling and drainage. | Proper mixing ratios and curing times are crucial for concrete. Heavy lifting involved. |

| Frame Assembly | Cutting and joining lumber or metal, erecting the frame according to the design. | Carpentry or metalworking skills, ability to follow plans accurately. | Safety precautions are essential when working with power tools. Precision is important for a structurally sound frame. |

| Covering Installation | Attaching plastic film or other covering material to the frame, ensuring a tight seal. | Basic handyman skills, attention to detail. | Working at heights may be required. Proper sealing is crucial to prevent heat loss. |

| Insulation | Installing insulation materials (straw bales, foam boards, etc.). | Basic handyman skills, ability to follow instructions. | Proper handling and placement of insulation materials are important for effectiveness. |

| Digging the wall | Build the north wall. | Physical labor, basic construction. | Time commitment can be significant. |

Be honest with yourself. Can you safely and competently handle these tasks? If not, it’s better to hire a professional for certain parts of the project. My first greenhouse was a learning experience! I underestimated the time it would take to level the ground, and I ended up having to redo a section of the foundation.

Bulk Purchasing: Getting Better Prices?

Frustrated by high material prices when buying small quantities? Bulk purchasing can unlock discounts.

Purchasing materials in bulk, especially for larger greenhouses or multiple projects, can often result in significant discounts from suppliers. This applies to lumber, plastic film, insulation, and other materials.

But it’s not just about buying more; it’s about buying smarter.

Strategies for Effective Bulk Purchasing:

| Strategy | Description | Considerations |

|---|---|---|

| Plan Ahead | Carefully calculate the quantities of materials needed for the entire project before making any purchases. | Avoid overbuying and ending up with excess materials. Accurate measurements and a detailed materials list are essential. |

| Compare Suppliers | Get quotes from multiple suppliers to compare prices and find the best deals. | Don’t be afraid to negotiate prices, especially for large orders. Consider factors like delivery costs and supplier reputation. |

| Group Purchases | If possible, collaborate with other growers or community members to combine orders and increase purchasing power. | This can be a great way to access bulk discounts even if your individual needs are relatively small. Requires coordination and communication with others. |

| Consider Off-Season | Some materials may be cheaper during the off-season when demand is lower. | This may require planning your project further in advance. Storage space may be needed for materials purchased off-season. |

| Check for Sales | Look for sales and promotions offered by suppliers. | Sign up for email newsletters or follow suppliers on social media to stay informed about discounts. |

| Directly buy from China | The construction cost of the Chinese-style solar greenhouse is 45 to 65 RMB per square meter. Consider sourcing directly from Chinese manufacturers. | You can communicate with Chinese suppliers, like CFGET, to obtain competitive pricing and potentially customized solutions. Be mindful of shipping costs, lead times, and potential import duties when sourcing internationally. |

Think of it like buying in bulk at a grocery store – you often get a lower price per unit. The same principle applies to greenhouse materials.

Conclusion

Building a Chinese greenhouse doesn’t have to break the bank. Material choice, smart design, DIY (if you have the skill), and buying in bulk are key to cost control. Careful planning saves money!