Cold temperatures cut growing seasons short, leaving crops unfinished and profits unrealized. Unpredictable climate patterns further threaten production schedules, but heated greenhouses offer a powerful solution.

Heated greenhouses transform seasonal limitations into year-round growing opportunities. By maintaining optimal temperatures regardless of external conditions, they enable continuous production, diverse crop cultivation, and significant profit extension throughout traditionally unproductive months.

After 28 years developing greenhouse solutions at CFGET, I’ve seen firsthand how heated environments revolutionize agricultural operations worldwide. Our clients consistently report production increases of 30-40% after implementation. Let me share what I’ve learned about these systems and how they might benefit your operation.

Don’t Miss:——Exploring Greenhouse Types: Finding the Perfect Structure for Your Needs

You might like:——How Do Greenhouses Stay Warm When It’s Freezing Outside?

Why Invest in a Greenhouse with Heat? Key Benefits Explained?

Traditional growing faces severe seasonal constraints, forcing operations to shut down during colder months. Many growers watch helplessly as potential revenue freezes alongside their fields each winter.

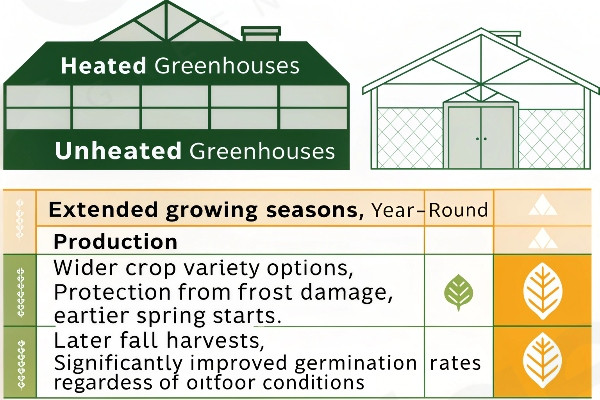

Heated greenhouses deliver multiple advantages: extended growing seasons (often year-round production), wider crop variety options, protection from frost damage, earlier spring starts, later fall harvests, and significantly improved germination rates regardless of outdoor conditions.

I remember visiting a client in Northern Europe who transformed their operation with our heated greenhouse system. Before installation, they operated just 7 months annually. Now they maintain production all 12 months, growing specialty herbs that command premium winter prices. Beyond simple season extension, heated greenhouses create entirely new business opportunities.

The benefits extend far beyond basic temperature maintenance. With proper heating, you gain precise environmental control that optimizes plant health and productivity. This translates to faster growth cycles, allowing multiple harvests where single seasons were once the norm. Many of our clients report 30-45% increases in annual yield after implementing heating solutions.

Temperature stability also significantly reduces crop losses. One Central Asian client previously lost approximately 20% of early seedlings to cold snaps annually. After installing our system, losses dropped below 3%, representing substantial savings. The predictability factor cannot be overstated – with heating, growing schedules become reliable rather than weather-dependent guesses.

For high-value crops especially, the return on investment often surprises clients. A Southeast Asian orchid grower recouped their entire heating system cost within 18 months through improved bloom consistency and timing. The ability to hit market windows precisely represents a competitive advantage that seasonal growers simply cannot match.

Common Greenhouse Heating Systems: Pros & Cons?

Choosing between numerous heating options overwhelms many growers, leading to costly mistakes or inefficient systems. Without proper guidance, energy bills can quickly erase the profit margins you hoped to gain.

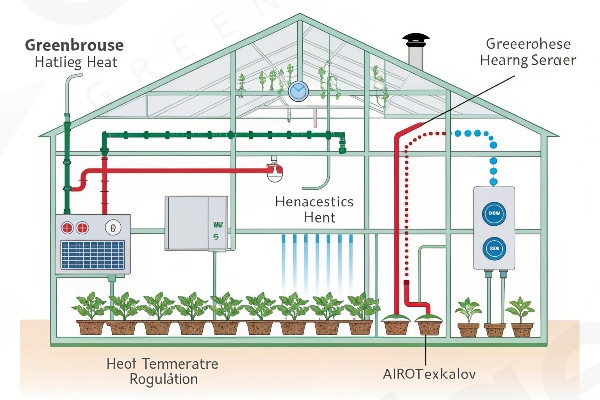

Greenhouse heating systems include forced-air heaters (quick heating, potential uneven distribution), radiant systems (efficient, consistent heat at plant level), hot water systems (excellent uniformity, higher installation costs), and electric options (clean, precise control but potentially expensive operation).

The heating system forms the foundation of your extended growing season. In my experience working with growers across three continents, no single solution fits every operation. Each system brings distinct advantages and limitations worth careful consideration.

Forced-air systems remain popular for their relatively low upfront costs and straightforward installation. These systems use propane, natural gas or electric heaters to warm air, then distribute it via fans. The primary advantage is quick temperature adjustment, critical during sudden cold fronts. However, heat distribution often proves uneven, creating hot and cold spots that affect crop uniformity. I’ve seen growers successfully mitigate this using horizontal air flow fans to improve circulation.

Radiant heating systems deliver heat directly to plants and soil rather than simply warming air. The infrared radiation travels until it contacts solid objects, creating efficient plant-level warming. One European tomato producer switched from forced air to radiant systems and reported 23% energy savings1 while achieving more consistent fruit development. The drawback? Initial installation costs typically exceed those of forced-air systems.

Hot water systems utilize boilers connected to pipes or tubes running throughout the greenhouse. While installation represents a significant investment, the operational efficiency often makes them the most economical long-term option for larger operations. The water maintains temperature longer than air, providing steadier conditions and reducing heating system cycling. In Central Asia, where temperature swings can be extreme, our hot water system clients consistently report the most stable growing environments.

For smaller operations or supplemental heating needs, electric options like heating mats, cables, and infrared panels offer precise zone control. Their clean operation eliminates combustion concerns, though electricity costs vary dramatically by region. One research facility client uses electric heating exclusively for their experimental growing chambers, citing the control precision as worth the additional expense.

Key Factors to Consider for Your Heated Greenhouse Setup?

Improper heating system sizing wastes thousands in unnecessary equipment or leaves crops vulnerable during coldest periods. Many growers overlook crucial climate factors, creating inefficient systems that drain profits rather than enhance them.

When planning a heated greenhouse, evaluate: structure size and insulation quality, local climate extremes, crop temperature requirements, available energy sources, backup systems, future expansion plans, and total budget including operating costs over 5+ years.

Selecting the right heating system involves much more than comparing equipment prices. Based on my experience with hundreds of installations across diverse climates, I’ve found that thorough initial assessment prevents costly modifications later.

First, accurate heat load calculations are essential. This requires understanding both your structure’s characteristics and local climate data. The heat retention capabilities of different covering materials vary dramatically – double-layer polycarbonate retains approximately 40% more heat than single-layer glass. Similarly, the difference between needed capacity in temperate versus extreme continental climates can easily double equipment requirements. I recommend analyzing at least 10 years of local temperature data to account for extremes rather than averages.

Insulation quality directly impacts ongoing operational costs. In a project we completed in Eastern Europe, adding thermal screens reduced nighttime heating requirements by 38%. The screens paid for themselves in under two years through energy savings1. For cold-region greenhouses, our top insulation systems combined with four-sided insulation curtains create multiple heat barriers. These systems are particularly effective during winter nights when temperature differentials reach their maximum.

Your specific crop requirements should drive minimum temperature settings. Tropical ornamentals may require consistent temperatures above 18°C (65°F), while cool-season vegetables might thrive at just 10°C (50°F). This difference translates to substantially different equipment needs and operating costs. I typically recommend sectioning larger greenhouses to create temperature zones, allowing efficient resource allocation based on plant needs.

Energy source availability and reliability vary dramatically by region. Natural gas offers economic advantages where available but requires backup planning in areas with potential supply disruptions. In remote locations, propane storage systems provide independence but at higher fuel costs. Increasingly, our clients integrate renewable energy sources – one Southeast Asian operation now powers heating pumps primarily through solar generation, with traditional fuel as backup only.

Redundancy planning prevents catastrophic losses. A Central Asian client lost an entire crop during an extended power outage until we implemented a generator-backed system with automatic switching. The additional 15% system cost would have saved them ten times that amount in prevented losses.

Maximizing Efficiency: Tips for Heating Your Greenhouse Economically?

Energy costs often shock new greenhouse operators, sometimes consuming 30% or more of operating budgets. Without efficiency strategies, heating expenses can quickly erase the profit advantages of extended growing seasons.

Economic greenhouse heating combines intelligent infrastructure design, operational best practices, and targeted heat delivery. Implement insulation curtains, seal air leaks, maintain equipment regularly, use zone heating for different crops, and consider heat storage systems to capture daytime solar gain.

After decades helping clients optimize their greenhouse heating, I’ve found that efficiency comes from systematic implementation of complementary strategies rather than single solutions. The most successful operations combine structural, mechanical, and operational approaches.

Insulation represents your first and most important efficiency measure. Our Chengfei Greenhouse designs incorporate specialized insulation systems that significantly reduce heat loss. The top insulation reduces upward heat dissipation, while four-sided insulation curtains create an additional barrier against heat transfer. For film-type greenhouses in particularly cold regions, we often recommend designs with exterior slopes that both resist wind load and create double-layer insulation effects. One Northern European client reduced heating costs by 42% after implementing our comprehensive insulation package.

Strategic heat distribution often yields surprising efficiencies. Rather than maintaining uniform temperatures throughout the entire structure, consider crop-specific zones. Root-zone heating through floor pipes or heating cables can maintain plant health while allowing slightly cooler ambient air temperatures. This approach has proven particularly effective for germination areas and propagation benches, where soil temperature matters more than air temperature. A research client maintained optimal root development while reducing overall heating requirements by 25% through targeted delivery.

Heat retention systems capture daytime solar gain for nighttime use. Water barrels or tubes positioned to absorb sunlight during day hours release this stored heat gradually overnight. Though simple in concept, proper implementation requires careful placement and volume calculations. In a Mediterranean installation, we incorporated 5,000 liters of water storage that moderated nighttime temperature drops by 4-6°C without any active heating during transitional seasons.

Equipment maintenance significantly impacts efficiency. Clean heat exchangers, burners, and distribution systems operate more efficiently and provide more consistent heating. I recommend establishing a regular maintenance schedule that includes professional system checks before each heating season. This preventive approach typically improves efficiency by 10-15% compared to reactive maintenance.

Modern control systems that integrate weather forecasting can optimize heating cycles. Rather than responding solely to current conditions, predictive controls prepare for upcoming temperature changes, reducing energy waste from heating system lag. These systems particularly benefit operations in variable climates, where rapid weather changes create challenging heating conditions. The initial technology investment typically returns savings within 2-3 heating seasons.

Conclusion

A properly designed heated greenhouse transforms seasonal limitations into year-round growing opportunities. By selecting appropriate systems, implementing efficient designs, and following operational best practices, you can extend your productive season while maintaining reasonable energy costs.