Starting a new venture feels daunting, especially weighing risks against rewards. You wonder if pouring resources into greenhouse farming guarantees a return. It’s a significant commitment.

Yes, commercial greenhouse farming presents a strong opportunity for profit. It allows for year-round cultivation, higher yields, better quality control, and protection from adverse weather, leading to potentially high returns on investment when managed effectively.

Making the jump into this field involves understanding several key areas. From setting up your operation to analyzing costs and choosing what to grow, each step matters. Based on my experience helping growers worldwide for over 28 years, success comes from careful planning and execution. Let’s explore how you can turn a greenhouse into a thriving business.

Don’t miss out:——Commercial Hydroponic Greenhouse Systems: How Do Design, Construction, and ROI Interconnect?

Starting a Greenhouse Farming Business: Is There a Clear Step-by-Step Guide?

The idea of starting a farm is exciting, but the process seems complex. Where do you even begin? Navigating the steps feels overwhelming without a clear map.

Starting involves several key phases: thorough market research, crafting a solid business plan, selecting an ideal site, choosing the right greenhouse, securing funds and permits, setting up, selecting crops, and finally, planting and marketing your produce.

Let’s break down the journey of launching your greenhouse farming business. I’ve seen countless clients through this process at CFGET, and while each journey is unique, the core steps remain consistent. First, you absolutely must understand your market. Who are your potential customers? What are they buying? What are competitors doing? This research forms the foundation of your business plan. Your plan needs details: your mission, operational strategy, financial projections (costs, revenue, profit), and marketing approach. Don’t skip this; it’s vital for securing funding and guiding your decisions. Site selection comes next. Consider factors like climate, sunlight exposure, water access, soil quality (if applicable), proximity to markets, and local zoning regulations. Choosing the right greenhouse structure is crucial. This depends on your climate, crops, and budget. We at CFGET offer various designs, from simple poly tunnels to advanced multi-span structures, tailored to needs from humid Southeast Asia to harsh Central Asian climates. Securing financing and necessary permits often happens concurrently. Once you have the land and structure type decided, you can finalize setup – installing irrigation, climate control, lighting, and benches. Then comes the exciting part: selecting your crops based on market demand and suitability, followed by planting and nurturing them. Finally, you need a plan to sell your harvest, whether through local markets, restaurants, wholesale, or direct-to-consumer models.

| Phase | Key Actions | Considerations |

|---|---|---|

| 1. Research & Plan | Market analysis, Competitor research, Business plan development | Target audience, Pricing, Financial projections, Legal structure |

| 2. Setup Foundation | Site selection, Greenhouse selection & design, Funding acquisition, Permits | Climate, Water access, Zoning, Budget, Structure type (Poly, Glass) |

| 3. Operational Setup | Greenhouse construction, System installation (Irrigation, HVAC, Lighting) | Supplier choice (like CFGET for reliability), Installation expertise |

| 4. Cultivation | Crop selection, Sourcing seeds/plants, Planting, Growing management | Market trends, Climate suitability, Pest/disease control, Yield goals |

| 5. Sales & Marketing | Identify sales channels, Develop marketing strategy, Build relationships | Wholesale, Retail, Direct-to-consumer, Branding, Logistics |

Throughout my years, I’ve seen clients in Europe focus heavily on automation and sustainability certifications, while those in Southeast Asia prioritize rapid setup and managing high humidity. Central Asian clients often need structures engineered for extreme temperatures and reliable long-term support. We tailor our approach accordingly. For instance, a project in Kazakhstan required reinforced structures for heavy snow loads, while a Malaysian project needed advanced ventilation systems. Starting requires diligence, but following these steps methodically significantly increases your chances of success. It’s not just about building a greenhouse; it’s about building a sustainable business. Remember that story I told you about the farm in Thailand? They started small, focusing on high-demand herbs for local restaurants, meticulously following their plan, and reinvesting profits. Now they operate a multi-unit facility. It takes time, but it’s achievable.

Don’t miss out:——What is a Hydroponic Greenhouse? The Ultimate Guide to Soilless Growing

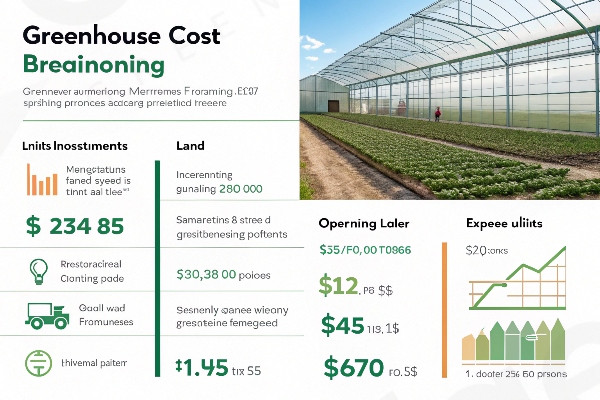

Greenhouse Farming Cost Analysis: What Are the Real Investment, Operating Expenses, and ROI?

Worried about the money needed for greenhouse farming? The potential costs, from building to running it daily, can seem like a huge barrier, making you question its feasibility.

Costs include initial investments (land, structure, systems) and ongoing operating expenses (utilities, labor, supplies). While significant, strategic planning and efficient management can lead to a strong Return on Investment (ROI) over time.

Understanding the financial side is critical before you dive in. Let’s be realistic: starting a commercial greenhouse isn’t cheap, but the potential returns can justify the expense. I always advise clients to perform a detailed cost analysis. The initial investment, or Capital Expenditure (CapEx), is usually the largest hurdle. This includes acquiring land (if you don’t own it), purchasing the greenhouse structure itself – which varies greatly in price depending on size, type (poly tunnel, multi-span, glass), and features – and installing essential systems. These systems are key: irrigation (drip, sprinkler, hydroponic), climate control (heating, ventilation, cooling – HVAC), possibly supplemental lighting, benches or growing beds, and control systems. Think about equipment too, like tractors, tools, and packing materials. At CFGET, we provide detailed quotes breaking down these structural and system costs based on the specific project needs, whether it’s a simple setup for a small grower or a large, automated facility for a major agricultural producer. For example, a basic poly tunnel might start lower, while a high-tech glass greenhouse suitable for research institutions in Europe, demanding precise control, will require a much larger investment.

Operating Expenses (OpEx) are the ongoing costs to keep the farm running. These include utilities (water, electricity, fuel for heating), labor (planting, harvesting, maintenance, management), supplies (seeds, seedlings, fertilizers, pest control, packaging), maintenance and repairs, insurance, and marketing costs. These vary significantly based on your location (energy costs), crop type (labor intensity), and management efficiency. We help clients design systems for efficiency; for instance, using energy-efficient heating or water-recirculating hydroponic systems can dramatically reduce OpEx, a key concern for growers everywhere, but especially vital for profitability in competitive European markets.

Calculating the Return on Investment (ROI) involves projecting your revenue based on expected yields and market prices for your chosen crops, then subtracting your CapEx and OpEx over a specific period. Key factors influencing ROI are crop choice (high-value crops generally yield better returns), market demand and pricing, yield per square meter (greenhouses boost this significantly compared to open fields), and operational efficiency. Based on data from our 1200+ projects across 20 countries, well-managed greenhouse farms typically see positive ROI within 3-7 years, sometimes faster for high-value crops or in strong markets.

| Cost Category | Examples | Key Considerations |

|---|---|---|

| Initial Investment (CapEx) | Land Purchase/Lease, Greenhouse Structure, Irrigation System, HVAC, Lighting, Benches, Equipment | Size, Type (Poly/Glass), Technology level, Location, Supplier (e.g., CFGET) |

| Operating Expenses (OpEx) | Utilities (Water, Energy), Labor, Seeds/Plants, Nutrients, Pest Control, Packaging, Maintenance, Insurance, Marketing | Efficiency, Crop needs, Labor costs, Market access, Energy prices |

| ROI Factors | Crop Market Value, Yield Quantity & Quality, Time to Market, Production Costs | Market demand, Growing efficiency, Management skill, Scale of operation |

I recall working with a group of growers in Central Asia where extreme winters meant high heating costs were a major concern. We designed a multi-span greenhouse with double-layer poly coverings and thermal screens, significantly reducing their energy OpEx and making their vegetable production profitable year-round despite the climate challenges. Similarly, for Southeast Asian clients battling heat and humidity, we focus on ventilation designs and cooling systems that are effective but also energy-conscious. Financial planning is crucial, and understanding these cost components helps you build a realistic budget and forecast profitability.

Choosing the Right Crops for Greenhouse Farming: How Do You Maximize Profitability?

Struggling to decide which crops to grow? Choosing incorrectly could waste time and money, jeopardizing your farm’s success. The pressure to pick profitable winners is high.

Maximize profitability by selecting crops based on high market demand, suitability for your specific greenhouse environment and climate, good yield potential, and commanding a premium price. Research local and export markets thoroughly.

Selecting the right crops is arguably one of the most critical decisions for greenhouse profitability. It’s not just about what can grow in a greenhouse, but what should grow to meet your financial goals. From my experience across diverse regions, the winners are usually those who align crop choice with market realities and their operational capabilities. First, intense market analysis is non-negotiable. What do consumers in your target market want? Are there unmet demands? Look at local grocery stores, restaurants, farmers’ markets, and even export opportunities. High-value niche crops often fetch better prices than common staples. Think gourmet greens, microgreens, specific herb varieties, out-of-season berries, colored bell peppers, specialty tomatoes, or even medicinal plants like cannabis (where legal and regulated). These often have higher profit margins.

Consider your greenhouse capabilities and local climate. Some crops need highly controlled environments (precise temperature, humidity, light) only achievable in advanced greenhouses, common requests from our European research clients. Others are more forgiving. Your climate also dictates heating/cooling needs, impacting costs. For instance, growing cool-weather crops in a hot climate like parts of Southeast Asia requires significant investment in cooling, potentially eating into profits unless the market price justifies it. We often advise clients in such regions on heat-tolerant varieties or adapting greenhouse designs for better natural ventilation. Conversely, in colder regions like Central Asia, the cost of heating dictates crop choices, favoring those that tolerate cooler temps or justify the heating expense with high value.

Yield potential and growth cycle are also important. Crops that produce abundantly per square meter and have relatively short growth cycles allow for more harvests per year, maximizing revenue from your expensive greenhouse space. Tomatoes, cucumbers, peppers, and leafy greens are popular for this reason. However, don’t overlook crops with longer cycles if their market value is exceptionally high. Finally, assess the required grower expertise and labor intensity. Some crops are relatively easy to manage, while others require specialized knowledge for pest control, pollination, or nutrient management.

| Factor | Key Questions to Ask | Examples & Considerations |

|---|---|---|

| Market Demand | What crops are popular locally/regionally? Are there niche markets? What’s the price? | High-value: Specialty greens, herbs, berries, medicinal plants. Volume: Tomatoes, peppers. |

| Climate/Greenhouse Fit | Can my greenhouse provide the required environment cost-effectively? What grows well locally? | Heat-tolerant varieties (SE Asia), Cold-hardy options (Central Asia), Specific light needs. |

| Profitability | What is the potential yield? What is the market price vs. production cost? | Calculate profit per square meter per year. Compare different crop options. |

| Growth Cycle | How long from planting to harvest? How many cycles per year? | Short cycles (leafy greens) vs. Longer cycles (some fruits, medicinal plants). |

| Expertise/Labor | Do I have the knowledge? How much labor is needed for planting, care, harvest? | Simple (some greens) vs. Complex (hydroponic systems, specific pest management). |

I remember a client in the Americas wanting to grow exotic tropical fruits. While technically possible in a highly controlled greenhouse, the setup and energy costs were prohibitive compared to the potential market price, which couldn’t compete with imported fruit. We worked together to identify high-demand specialty herbs1 and edible flowers for the local high-end restaurant market instead. This pivot, based on realistic assessment, led to a very profitable venture. Crop selection is a blend of agronomy, market research, and business sense. Getting it right sets the stage for success. Based on our insight, 90% of the greenhouses we build are used for diverse agricultural crops – vegetables, fruits, medicinal plants – showing the wide range of possibilities when choices are made strategically.

China-Made Greenhouses: Are They Quality, Affordable Solutions for Commercial Growers?

Considering a greenhouse from China? You might worry if lower prices mean sacrificing quality or durability, especially for a long-term investment like a commercial greenhouse.

Yes, reputable manufacturers in China, like CFGET with our 28 years of experience, provide high-quality, technologically advanced, and durable greenhouses at competitive prices, offering excellent value for commercial growers globally.

Let’s address this question directly, as it’s something I discuss often with potential clients from Europe, the Americas, Southeast Asia, and Central Asia. There’s a perception sometimes that "Made in China" automatically means lower quality, but in the commercial greenhouse sector, that’s often far from the truth. For decades, leading Chinese manufacturers have invested heavily in research, development, and quality control, becoming global leaders in providing sophisticated agricultural solutions. At CFGET, we’ve been part of this evolution since 1996. The key advantage is undoubtedly cost-effectiveness2. Due to economies of scale, efficient manufacturing processes, and established supply chains, we can typically offer greenhouse structures and systems at a more competitive price point compared to manufacturers in many Western countries. This makes commercial greenhouse farming more accessible, especially for new ventures or growers in developing markets.

However, affordability does not mean compromising on quality, at least not with established companies. We use high-quality materials, such as galvanized steel frames designed to withstand specific environmental loads (like snow in Central Asia or wind in coastal areas) and durable covering materials (polyethylene film, polycarbonate sheets, glass) suited to different climates and crop needs. Our designs incorporate modern technologies – automated climate control, efficient irrigation systems (including hydroponics and aeroponics), supplemental LED lighting, and integrated control software. These are the same technologies demanded by high-value growers and research institutions in Europe and America. We customize solutions; a grower in humid Southeast Asia might need different ventilation and covering options than one in arid Central Asia. Quality control is paramount throughout our manufacturing process, ensuring structures meet international standards. Our experience across 1200 projects in over 20 countries demonstrates the reliability and performance of our greenhouses in diverse conditions.

Of course, buyers should do their due diligence. Not all manufacturers are equal. Look for companies with a long track record, verifiable project references, clear communication, and strong after-sales support. Concerns about shipping and installation are valid. We manage logistics carefully and often partner with local teams or provide detailed instructions and support for installation, ensuring a smooth process for clients globally. Our long-term service guarantees and technical support provide peace of mind, addressing a key need for all our client types, from agents to large producers.

| Feature | CFGET Approach & Benefit | Relevance to Target Audience |

|---|---|---|

| Cost-Effectiveness | Competitive pricing due to efficient manufacturing & scale. | Makes projects feasible (SE Asia, Central Asia), Improves ROI (All regions). |

| Quality Materials | High-grade galvanized steel, Durable coverings (Poly, PC, Glass). | Ensures longevity & resilience to climate (Wind, Snow, Humidity) – crucial for all. |

| Advanced Technology | Integrated climate control, Efficient irrigation, Automation options. | Meets needs for precision (Europe/America), Improves efficiency & yields (All). |

| Customization | Designs tailored to climate, crop, budget. | Addresses specific regional needs (SE Asia humidity, Central Asia extremes, Euro/US standards). |

| Experience & Support | 28 years, 1200+ projects globally, Technical support, After-sales service, Local partners. | Builds trust, Ensures project success & long-term operation (Key for all clients). |

I recall a project with a large agricultural producer in Europe who was initially skeptical about sourcing from China. After visiting our facilities, reviewing our project portfolio, and discussing the technical specifications tailored for their high-precision needs, they moved forward. The project was completed successfully, delivering the required quality and technology within their budget. Choosing a Chinese greenhouse manufacturer like CFGET means accessing affordable, high-quality, and technologically sound solutions backed by decades of experience and global reach.

Conclusion

Commercial greenhouse farming offers a real path to profitability through controlled growing environments and potentially high yields. Success hinges on careful planning, cost management, smart crop choices, and selecting the right greenhouse partner like CFGET.