Choosing between light deprivation and indoor farming can make or break your agricultural investment. Both methods promise controlled growing conditions, but their costs and complexity differ dramatically.

Light deprivation greenhouses utilize natural light with blackout systems for precise photoperiod control, while indoor farming relies entirely on artificial lighting in climate-controlled environments. Light dep offers 40-60% lower energy costs but requires suitable climate conditions, whereas indoor farming provides complete environmental control at 3-5x higher operational expenses.

After 28 years in greenhouse manufacturing, I’ve witnessed the evolution from simple structures to sophisticated growing systems. The choice between light deprivation and indoor farming isn’t just about technology—it’s about matching your investment capacity with market demands and local conditions.

Key Advantages of Light Dep: Utilizing Natural Light to Reduce Energy Costs?

Light deprivation technology feels like nature’s gift to modern agriculture. The system harnesses free solar energy while maintaining precise control over plant growth cycles.

Light deprivation greenhouses reduce energy consumption by 40-60% compared to indoor farming by utilizing natural sunlight during optimal hours and deploying automated blackout systems for photoperiod manipulation. This approach cuts operational costs significantly while maintaining crop quality standards.

The beauty of light deprivation lies in its simplicity and effectiveness. During my visits to facilities across Southeast Asia, I’ve observed growers achieving remarkable results with minimal energy input. The system works by allowing natural sunlight to penetrate during active photosynthesis periods, then deploying blackout curtains or covers to create artificial night conditions when needed.

Energy savings represent the most compelling advantage. Traditional indoor farming facilities consume 30-40 kWh per square meter monthly for lighting alone. Light deprivation systems reduce this to 10-15 kWh by maximizing natural light utilization. The automated blackout systems operate on minimal power, typically consuming less than 2% of total facility energy requirements.

| Energy Consumption Comparison | Light Dep | Indoor Farming |

|---|---|---|

| Lighting (kWh/m²/month) | 10-15 | 30-40 |

| Climate Control (kWh/m²/month) | 8-12 | 15-20 |

| Total Energy Cost Reduction | 40-60% | Baseline |

Climate integration provides another significant benefit. Light deprivation systems work harmoniously with local weather patterns, reducing the burden on heating and cooling systems. In tropical regions like Thailand and Malaysia, natural ventilation combined with light deprivation creates optimal growing conditions without excessive energy consumption.

The technology proves particularly effective for light-sensitive crops requiring specific photoperiods. Cannabis cultivation, for example, benefits tremendously from precise light cycle control. Growers can trigger flowering phases exactly when market conditions are favorable, optimizing harvest timing and product quality.

Core Challenges of Indoor Farming: High Initial Costs and Technical Demands?

Indoor farming promises complete environmental control but demands substantial financial commitment and technical expertise. The initial investment can overwhelm even experienced growers.

Indoor farming requires 3-5 times higher initial investment than light deprivation systems, with LED lighting alone costing $200-400 per square meter. Technical complexity demands specialized staff and continuous monitoring systems, creating ongoing operational challenges for many facilities.

The financial reality of indoor farming hits hard during the planning phase. A typical 1,000 square meter indoor facility requires $800,000-1,200,000 in initial investment, compared to $300,000-500,000 for equivalent light deprivation infrastructure. LED lighting systems alone consume 40-50% of the total budget, with high-quality fixtures costing $200-400 per square meter.

Technical demands create another layer of complexity. Indoor systems require precise environmental control across multiple parameters: temperature, humidity, CO2 levels, air circulation, and lighting intensity. Each variable demands monitoring and adjustment throughout the growing cycle. I’ve seen facilities fail because operators couldn’t maintain the technical precision required for consistent results.

Staffing requirements escalate quickly. Indoor farming demands technicians familiar with electrical systems, HVAC operation, and plant physiology. Training costs and ongoing education add $20,000-30,000 annually to operational expenses. Many facilities struggle to find qualified personnel, especially in developing markets where technical expertise remains scarce.

| Investment Comparison | Light Dep | Indoor Farming |

|---|---|---|

| Initial Setup ($/m²) | 300-500 | 800-1,200 |

| Annual Operating Costs ($/m²) | 150-200 | 400-600 |

| Technical Staff Requirements | 1-2 operators | 3-5 specialists |

Energy consumption creates ongoing financial pressure. Indoor facilities typically consume 200-300 kWh per square meter monthly, translating to $30-50 in electricity costs depending on local rates. This operational burden continues regardless of crop performance or market conditions.

Equipment maintenance adds another cost layer. LED fixtures require replacement every 5-7 years, HVAC systems need regular servicing, and control systems demand software updates and calibration. These maintenance costs can reach 15-20% of initial investment annually.

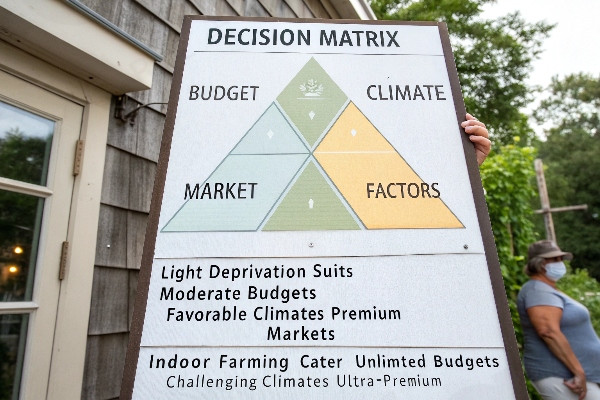

Key Factors for Choosing a Cultivation Method: Budget, Climate, and Target Market?

Selecting the right cultivation method requires careful analysis of your specific situation. Three critical factors determine which approach will succeed in your market.

Budget constraints, local climate conditions, and target market requirements form the decision triangle for cultivation method selection. Light deprivation suits moderate budgets in favorable climates targeting premium markets, while indoor farming serves unlimited budgets in challenging climates for ultra-premium products.

Budget analysis starts with honest financial assessment. Light deprivation systems require 60-70% less initial investment but depend on suitable climate conditions. If your available capital falls below $500,000 for a commercial operation, light deprivation offers the most viable path to profitability. Indoor farming demands substantial reserves beyond initial investment to cover operational costs during the first 18-24 months.

Climate evaluation determines feasibility more than any other factor. Light deprivation thrives in regions with consistent sunlight and moderate temperature variations. Mediterranean climates, parts of California, and certain areas in Australia provide ideal conditions. Extreme climates with harsh winters, excessive humidity, or limited sunlight make indoor farming1 more practical despite higher costs.

Market analysis reveals which approach matches customer expectations and price points. Premium cannabis markets often accept light deprivation2 products at 80-90% of indoor pricing, making the energy savings worthwhile. Ultra-premium markets demanding perfect consistency may require indoor precision, justifying the additional investment.

| Factor Analysis | Light Dep Advantage | Indoor Advantage |

|---|---|---|

| Budget Under $500K | Strong | Weak |

| Extreme Climate | Weak | Strong |

| Premium Market (80-90% pricing) | Strong | Moderate |

| Ultra-Premium Market | Moderate | Strong |

Geographic location influences infrastructure availability and costs. Remote locations may lack reliable electricity for indoor farming but offer abundant sunlight for light deprivation. Urban areas provide better technical support for complex indoor systems but may have higher energy costs that favor light deprivation2 efficiency.

Regulatory environment affects method selection significantly. Some regions restrict indoor cultivation or impose additional licensing requirements. Others offer incentives for energy-efficient growing methods, making light deprivation more attractive financially.

Scale considerations impact the decision differently at various production levels. Small operations under 500 square meters often find light deprivation more manageable, while large facilities above 2,000 square meters may justify indoor farming’s complexity through economies of scale.

Return on Investment (ROI) Considerations: Short-Term Gains vs. Long-Term Stability?

ROI calculations reveal the true financial impact of cultivation method selection. Short-term profitability often conflicts with long-term stability in agricultural investments.

Light deprivation systems typically achieve break-even within 18-24 months with 25-35% annual ROI, while indoor farming requires 36-48 months with 15-25% ROI. However, indoor facilities offer more predictable returns and higher product premiums in established markets.

Short-term financial performance favors light deprivation significantly. Lower initial investment and reduced operational costs create faster cash flow positive operations. A typical light deprivation facility begins generating positive cash flow within 6-9 months, compared to 12-18 months for indoor operations. This timing difference can determine project viability for many investors.

The mathematics of ROI calculation shows clear patterns. Light deprivation systems with $400,000 initial investment and $150,000 annual operating costs can generate $250,000-300,000 annual revenue, producing 25-35% ROI. Indoor systems requiring $1,000,000 initial investment and $400,000 operating costs need $600,000-700,000 annual revenue for comparable returns.

| ROI Comparison | Light Dep | Indoor Farming |

|---|---|---|

| Break-even Period | 18-24 months | 36-48 months |

| Annual ROI | 25-35% | 15-25% |

| Cash Flow Positive | 6-9 months | 12-18 months |

| Revenue Required (per $1M invested) | $350K-400K | $600K-700K |

Long-term stability considerations shift the analysis. Indoor farming provides more predictable yields and quality consistency, reducing market risk over time. Weather-related crop losses affect light deprivation systems more significantly, creating revenue volatility that may concern some investors.

Market evolution impacts long-term returns differently. As indoor farming technology improves and costs decrease, the ROI gap may narrow. However, energy costs continue rising globally, potentially widening the operational cost advantage of light deprivation systems.

Risk assessment reveals different vulnerability patterns. Light deprivation systems face weather-related risks but lower financial exposure. Indoor farming faces technical failure risks and higher financial stakes. Insurance costs reflect these differences, with indoor facilities typically paying 30-50% higher premiums.

Scalability affects long-term ROI projections. Light deprivation systems scale more affordably, allowing gradual expansion as markets develop. Indoor farming requires substantial capital commitments for each expansion phase, potentially limiting growth opportunities for smaller operators.

Conclusion

Light deprivation offers superior ROI for budget-conscious growers in suitable climates, while indoor farming provides premium quality control for high-value markets despite higher costs.