Your high-value crops need perfect conditions to reach their full potential. But inconsistent light and environment can slash both yield and quality, hurting your profits.

You can maximize crop yield and quality by using either light deprivation greenhouses or indoor farms. Light dep manipulates natural sunlight for photoperiod-sensitive crops, while indoor farms create a perfectly controlled artificial environment for consistent, year-round production of high-value produce.

I often speak with growers who are at a crossroads. They want to produce the absolute best quality crops, whether it is medicinal herbs with specific potency or leafy greens with the perfect texture. They ask me, "Should I build a high-tech greenhouse or a fully enclosed indoor farm?" There is no single right answer. The best choice depends entirely on your specific crop, your local climate, your budget, and your long-term business goals. I remember a client planning a large-scale medicinal cannabis operation. We spent weeks analyzing the pros and cons of each system for their specific strain and market. This deep dive showed that both paths can lead to incredible success, but they are very different journeys. Let’s walk through the key differences so you can understand which path is right for you.

How Does Light Dep Technology Boost Yield by Controlling the Photoperiod?

Your light-sensitive crops flower at the wrong time, or not at all. This unpredictable cycle ruins your harvest schedule and market timing. We give you complete control.

Light deprivation (light dep) technology uses automated blackout systems to control the hours of light a plant receives. This manipulation of the photoperiod tricks plants into flowering on demand, enabling multiple harvests per year and maximizing your total yield.

The core principle behind light deprivation is a plant science concept called photoperiodism. Many plants, especially valuable ones like medicinal cannabis, chrysanthemums, or poinsettias, have an internal clock that is tied to the length of the day. They are genetically programmed to enter their flowering or reproductive stage only when the days get shorter, signaling the arrival of autumn. A light deprivation greenhouse gives you the power to create "autumn" whenever you want. By using automated blackout curtains, you can artificially create long nights of 12 or more hours of complete darkness, even in the middle of summer when the days are long. This control is a game-changer. I have worked with growers who went from one or two natural harvest cycles per year to four or even five perfectly timed, high-quality harvests. This technology does not just increase yield. It multiplies it. It turns your greenhouse into a year-round production factory that is aligned with your market demands, not the seasons.

The system itself is a marvel of simple, effective engineering. It consists of specially designed, multi-layered blackout tarps that are 100% opaque. Even a small light leak during the dark period can confuse the plants and disrupt the flowering cycle. These tarps are attached to a motorized system, often a rack-and-pinion drive, that is controlled by a central timer or an advanced climate computer. At the programmed time each day, the system automatically covers the entire crop, and then uncovers it the next morning. It is precise and reliable.

However, a major challenge arises when the blackout curtain is closed. The greenhouse becomes a sealed, dark, and warm box. Without sunlight driving transpiration, humidity can skyrocket very quickly. This creates a perfect breeding ground for fungal diseases like botrytis or powdery mildew. Therefore, a successful light dep system is not just about the curtains. It must be fully integrated with a powerful ventilation and dehumidification system. We always install high-capacity circulation fans and dehumidifiers that are programmed to run during the dark cycle. This keeps the air moving and pulls excess moisture out, protecting the valuable crop from disease. It is this integration of systems that separates a professional, reliable light dep greenhouse from a risky amateur setup.

| Feature | Function | Impact on Yield |

|---|---|---|

| Automated Blackout Curtains | Simulate short days by blocking all light | Triggers flowering on demand for multiple harvests per year |

| 100% Light-Proof Tarp Material | Prevents any light leaks during the dark period | Ensures the flowering cycle is not interrupted or delayed |

| Integrated Dehumidification | Removes excess moisture during dark periods | Prevents fungal diseases that can destroy the crop |

| Programmable Controller | Automates the entire light cycle | Reduces labor costs and eliminates human error |

How Do Indoor Farms Guarantee High Yields by Optimizing Every Parameter?

Outdoor factors and even greenhouse climates have variables you cannot control. This inconsistency leads to unpredictable yields and quality. We remove all variables for guaranteed results.

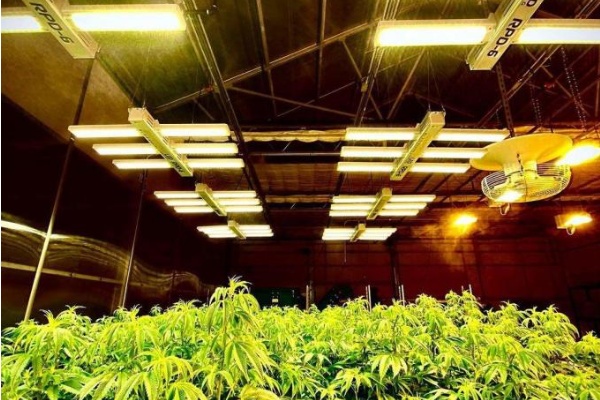

Indoor farms guarantee high yields by creating a completely closed-loop environment. They use precise LED lighting, HVAC systems, and automated fertigation to optimize every parameter—light, temperature, humidity, CO2, and nutrients—for perfect, repeatable growth cycles.

An indoor farm, often called a vertical farm or a plant factory, represents the peak of Controlled Environment Agriculture (CEA). It is about taking control to the absolute extreme. Imagine growing a crop in a laboratory. That is the philosophy here. There are no windows. The weather outside is completely irrelevant. Whether it is a blizzard in Kazakhstan or a heatwave in Southeast Asia, the conditions inside the grow room remain absolutely perfect, 24 hours a day, 365 days a year. This total control leads to astonishing results. Growth cycles can be shortened dramatically. For example, a head of lettuce that takes 60 days to grow in a field might be ready in just 30 days indoors. Because you control the light, you can stack layers of crops vertically, multiplying your yield per square meter of floor space by a factor of ten or more.

I once toured a vertical farm we helped design for a client in a major city. They were growing basil and other herbs for high-end restaurants. The facility was in the basement of a warehouse, a place with zero natural light. But inside, it was a perfectly controlled world. The air was filtered. The temperature never wavered by more than half a degree. The LED lights provided a custom "light recipe" designed to maximize the aromatic oils in the basil. The result? They produced a crop every 22 days, with a quality and consistency that was impossible to achieve outdoors. The chefs they supplied loved it because every single delivery was identical in flavor, size, and texture. This is the power of removing all variables.

The technology required is substantial. The heart of the system is a sophisticated HVAC (Heating, Ventilation, and Air Conditioning) unit that manages temperature and humidity with extreme precision. CO2 levels are often enriched to 1000-1500 parts per million (ppm), which can supercharge photosynthesis and boost growth rates. The lighting is provided entirely by advanced, programmable LED fixtures. Nutrient delivery is typically done through hydroponic, aeroponic, or aquaponic systems, where a computer-controlled system mixes and delivers a perfect nutrient solution directly to the plant roots. While the initial investment is high, the payoff is predictability. You can guarantee your yield, your harvest date, and your quality with a level of certainty that is simply not possible in any other form of agriculture.

| Environmental Parameter | Typical Indoor Farm Control | Impact on High Yield |

|---|---|---|

| Light | Tunable LED Spectrum, 16-18 hours/day | Optimized photosynthesis, faster growth, higher density |

| Temperature | Constant optimal temp (e.g., $$21^\circ C$$), no fluctuations | Eliminates heat/cold stress, maximizes metabolic rate |

| Humidity | Precise Relative Humidity (e.g., 60% RH) | Prevents disease, optimizes transpiration |

| CO2 Levels | Enriched to 1000-1500 ppm | Significantly boosts the rate of photosynthesis |

How Does Natural Sunlight Compare to Artificial Spectrum for Flavor and Nutrition?

You worry that crops grown under artificial lights lack the flavor and nutrients of sun-grown produce. This perception can affect your market price and customer trust.

Natural sunlight offers a full, dynamic spectrum that produces complex flavor profiles. However, advanced artificial LED spectrums can be tailored to enhance specific compounds, potentially increasing certain nutrients or aromatic oils beyond what sunlight can achieve consistently.

This is one of the most fascinating topics in modern agriculture, and one I discuss with clients all the time. There is a romantic idea that nothing can beat natural sunlight. And in many ways, that is true. Sunlight provides an incredibly broad and dynamic spectrum of light, including wavelengths like ultraviolet (UV) and far-red that we are only just beginning to understand. This full spectrum can trigger complex biochemical responses in plants, leading to the development of a wide range of secondary metabolites. These are the compounds that give a plant its unique flavor, aroma, and medicinal properties. A sun-grown tomato or herb often has a certain complexity that can be hard to replicate. This is the advantage of a light deprivation greenhouse system—it uses the free, full-spectrum power of the sun as its primary light source.

However, the story does not end there. The power of an indoor farm lies in its precision. With modern tunable LED lighting, we are no longer just trying to imitate the sun. We are trying to improve upon it for a specific goal. We know that blue light tends to promote leafy, vegetative growth and the production of certain antioxidants. We know that red light is critical for stimulating flowering and fruiting. We can now go much further. By creating specific "light recipes," we can use light as a tool to steer a plant’s biology. For example, by applying a specific dose of UV-A light at the right time, we can signal a lettuce plant to produce more red pigments, making it more visually appealing and potentially more nutritious. For medicinal herbs, we can use a specific ratio of red to far-red light to increase the concentration of the desired active compounds. It is like being a conductor of a plant orchestra, using light to tell each section what to play. So, while sunlight provides a beautiful symphony, LEDs allow you to command a powerful solo from a specific instrument.

The choice depends on the goal. For a crop valued for its traditional, complex flavor profile, the natural light from a greenhouse is often ideal. For a crop where the goal is to maximize a single, specific compound—like the CBD content in hemp or the lycopene in a tomato—a highly targeted indoor LED system might actually produce a more valuable and potent final product. It is not about which is "better," but which is the right tool for the job.

| Light Source | Key Advantage | Impact on Flavor/Nutrition | Best For |

|---|---|---|---|

| Natural Sunlight (Greenhouse) | Full, dynamic spectrum | Promotes complex, wide-ranging flavor/aroma profiles | Crops valued for traditional, nuanced flavor |

| White Full-Spectrum LED | Good imitation of sunlight, consistent | Creates a solid, well-rounded profile | General purpose, replacing sunlight |

| Red/Blue "Blurple" LED | Energy efficient for photosynthesis | Strong growth, but can miss key compounds | Basic vegetative growth, leafy greens |

| Tunable Spectrum LED | Precise control over wavelengths | Can target and boost specific compounds (oils, nutrients) | High-value medicinal or nutraceutical crops |

How Do Pest and Disease Risks Differ Between These Two Systems?

A single pest or disease outbreak can wipe out your entire high-value crop. The risk is always present, but the source of the threat is different in each system.

Light dep greenhouses have a higher risk of pests and diseases entering from the outside. Indoor farms are nearly sealed, reducing this risk, but if a pathogen does get in, the dense environment can cause it to spread very rapidly.

In a light deprivation greenhouse, your primary battle is with the outside world. Because the greenhouse needs large vents for cooling, there are many potential entry points for airborne fungal spores like powdery mildew or flying insects like aphids, thrips, and spider mites. The strategy here is defense in depth. Our designs always incorporate fine insect netting on all intake and exhaust vents. This is the first line of defense. The next step is often creating positive pressure, where fans push slightly more air into the greenhouse than is being exhausted. This creates an outward flow of air through any small gaps, making it harder for pests to fly in. An effective Integrated Pest Management (IPM) program is essential. This involves regular scouting to catch problems early, releasing beneficial insects that prey on pests, and using targeted, organic-friendly sprays only when absolutely necessary. The risk is constant, but it is manageable with good design and diligent practices.

An indoor farm presents a completely different set of challenges. It is a sealed fortress. The air is filtered, the water is sterilized, and there are no vents to the outside. In theory, it is a perfectly clean environment. The risk here is not constant pressure from the outside, but a catastrophic breach from the inside. The biggest threat is humans. A pest or a disease spore can be carried in on the clothing, shoes, or hands of a worker. It can also arrive on contaminated tools or new plant clones. Because of this, biosecurity is paramount. We design indoor farms with protocols similar to a clean room in a laboratory. This includes an airlock entry system, requiring workers to wear dedicated coveralls, gloves, and shoe covers. All tools are sterilized before entering the grow room. If a pathogen like pythium root rot or a pest like a spider mite does manage to get past these defenses, the results can be devastating. The warm, humid, and dense environment is a perfect incubator, and the problem can spread through the entire crop with terrifying speed. The focus is on total prevention, because a cure can be very difficult.

| System Type | Primary Risk Source | Key Prevention Strategy | Common Problems |

|---|---|---|---|

| Light Dep Greenhouse | External Environment (air, soil) | Integrated Pest Management (IPM), insect screens, positive pressure | Powdery mildew, aphids, thrips |

| Indoor Farm | Internal Contamination (humans, materials) | Strict Biosecurity Protocols (clean room, sterilization) | Pythium root rot, botrytis, spider mites (if introduced) |

Conclusion

The best choice depends on your crop, climate, and goals. Light deprivation greenhouses harness the sun for complex crops, while indoor farms offer total control for guaranteed, repeatable results.