Growing crops year-round seems impossible until you discover these two revolutionary farming methods that change everything.

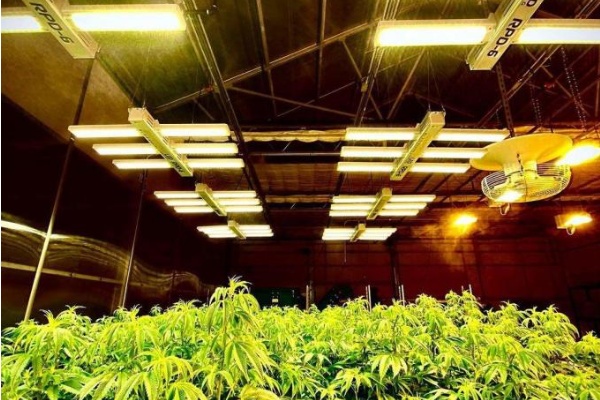

Light deprivation greenhouses and indoor farms represent two distinct approaches to controlled environment agriculture. Light dep systems manipulate natural sunlight cycles while indoor farms rely entirely on artificial lighting for complete environmental control.

When I first stepped into a light deprivation greenhouse five years ago, the contrast with traditional farming hit me immediately. The ability to control when plants receive light opened possibilities I never imagined. Since then, I’ve worked with both light dep greenhouses and indoor farms across Southeast Asia and Europe, helping growers choose the right system for their specific needs.

Environmental Control Capabilities Compared: Precision vs. Flexibility?

Traditional farming leaves you at nature’s mercy, but controlled environment agriculture puts you in the driver’s seat.

Light dep greenhouses offer moderate environmental control through blackout systems and climate management, while indoor farms provide absolute precision with fully automated systems controlling every environmental parameter.

I remember working with a cannabis grower in Thailand who struggled with inconsistent flowering cycles. We installed a light deprivation system that transformed his operation. Light dep greenhouses use automated blackout curtains to control photoperiods. You can trigger flowering in short-day plants whenever you want. The greenhouse still uses natural sunlight during the day, but you control when darkness falls.

Control Parameters Comparison

| Parameter | Light Dep Greenhouse | Indoor Farm |

|---|---|---|

| Temperature Control | ±2-3°C variation | ±0.5°C precision |

| Humidity Management | 60-80% RH range | Exact RH control |

| Light Intensity | Depends on weather | Consistent output |

| CO2 Regulation | Basic enrichment | Precise injection |

| Air Circulation | Natural + fans | Fully engineered |

Indoor farms take control to another level. Every aspect of the environment responds to computer commands. Temperature stays within half a degree of your target. Humidity levels remain exactly where you set them. Light intensity never varies unless you program it to. This precision comes at a cost though. The initial investment for indoor farms often reaches five to ten times that of light dep greenhouses.

Energy Efficiency Showdown: Natural Light Utilization vs. Artificial Lighting Systems?

Your electricity bill can make or break your farming operation, especially with rising energy costs worldwide.

Light dep greenhouses consume 60-80% less energy than indoor farms by utilizing free natural sunlight, while indoor farms require constant artificial lighting consuming 30-50 kWh per square meter monthly.

Last year, I consulted for two operations in the Netherlands. One used light deprivation, the other went fully indoor. The energy bills told a stark story. The light dep greenhouse spent €3,000 monthly on electricity for climate control and supplemental lighting. The indoor farm of similar size paid €15,000 just for LED lighting alone.

Energy Consumption Breakdown

| System Component | Light Dep (kWh/m²/month) | Indoor Farm (kWh/m²/month) |

|---|---|---|

| Lighting | 5-10 (supplemental) | 30-50 (primary) |

| Climate Control | 8-12 | 15-20 |

| Automation | 2-3 | 3-5 |

| Total Average | 15-25 | 48-75 |

Natural sunlight provides approximately 2000 μmol/m²/s on a clear day. Replicating this with LEDs requires significant power. Modern LED fixtures achieve about 2.5-3.0 μmol/J efficiency. To match sunlight intensity for 12 hours daily, you need roughly 650-750 watts per square meter. The math becomes daunting quickly.

However, indoor farms offer advantages in specific scenarios. They produce consistently throughout the year, unaffected by weather or seasonal changes. In regions with limited sunlight or extreme climates, the controlled environment justifies the energy cost. Some high-value crops like microgreens or pharmaceutical plants generate enough revenue to offset electricity expenses.

Crop Adaptability: Which Plants Thrive Best in Light Dep vs. Indoor Environments?

Not all crops respond equally to controlled environments, and choosing wrong can waste months of effort.

Light dep greenhouses excel with photoperiod-sensitive crops like cannabis and chrysanthemums, while indoor farms optimize production of leafy greens, herbs, and high-value specialty crops requiring precise environmental conditions.

Through my work with CFGET, I’ve seen growers succeed and fail based on crop selection alone. A client in Malaysia initially tried growing tomatoes in a light dep greenhouse. The results disappointed everyone. We switched to cannabis cultivation, and suddenly the same facility became highly profitable. The difference? Cannabis responds dramatically to photoperiod manipulation, while tomatoes care more about temperature and nutrition.

Optimal Crop Selection Guide

| Crop Category | Light Dep Performance | Indoor Farm Performance |

|---|---|---|

| Cannabis | Excellent – precise flowering control | Good – complete control but high cost |

| Leafy Greens | Moderate – seasonal variation | Excellent – year-round consistency |

| Herbs | Good – natural flavor development | Excellent – fast growth cycles |

| Tomatoes | Poor – limited benefit | Moderate – high energy cost |

| Strawberries | Good – extended seasons | Excellent – premium quality |

| Mushrooms | Excellent – darkness control | Good – sterile environment |

Light deprivation greenhouses work best for crops that need photoperiod control but still benefit from natural light intensity and spectrum. Cannabis remains the prime example. By controlling dark periods, you trigger flowering on demand. This allows multiple harvests per year instead of one outdoor season. Ornamental flowers like chrysanthemums and poinsettias also thrive under light dep systems.

Indoor farms shine with fast-growing, high-value crops. Lettuce completes its cycle in 35 days indoors versus 60 days in greenhouses. Basil and other herbs develop intense flavors under optimized LED spectrums. Microgreens fetch premium prices that justify electricity costs. Some growers report $200 per square meter monthly revenue from microgreens alone.

Technical Complexity and Maintenance: Operational Requirements and Potential Risks?

Complex systems fail in complex ways, and downtime costs money you cannot afford to lose.

Light dep greenhouses require basic mechanical knowledge and routine curtain maintenance, while indoor farms demand specialized technical expertise in lighting, HVAC, and computer systems with failure risks affecting entire crops.

I learned about technical risks the hard way. During a project in Singapore, an indoor farm’s HVAC system failed on a weekend. By Monday, the entire lettuce crop had wilted beyond recovery. The financial loss exceeded $50,000. In contrast, when a light dep curtain motor failed at another site, we simply operated it manually until repairs arrived. The crop barely noticed.

Technical Requirements Comparison

| Aspect | Light Dep Greenhouse | Indoor Farm |

|---|---|---|

| Staff Training | 2-4 weeks basic | 2-3 months specialized |

| Daily Monitoring | 2-3 hours | 4-6 hours |

| Backup Systems | Manual override possible | Critical redundancy needed |

| Maintenance Cost | 3-5% of revenue | 8-12% of revenue |

| Common Failures | Curtain motors, timers | Lights, HVAC, controls |

Light deprivation systems use straightforward technology. Blackout curtains deploy on timers or light sensors. Climate control involves fans, vents, and basic heating or cooling. Most problems have simple solutions. A torn curtain gets patched. A stuck motor gets replaced. Your maintenance team needs basic mechanical skills and attention to detail.

Indoor farms operate like data centers that happen to grow plants. LED drivers fail without warning. Environmental control computers crash. Sensors drift out of calibration. Each component links to others in complex ways. When one system fails, cascading problems follow quickly. You need technicians who understand electronics, programming, and horticulture equally well. Finding such people challenges even well-funded operations.

Conclusion

Light dep greenhouses balance natural resources with control, while indoor farms maximize precision at higher costs. Choose based on your crops, climate, and technical capabilities for optimal results.