Choosing the wrong greenhouse covering can destroy your entire crop investment. Many commercial growers face this exact problem when deciding between polycarbonate and glass materials.

The choice between polycarbonate and glass greenhouses depends on your local climate, crop requirements, and budget constraints. Polycarbonate offers better insulation and impact resistance, while glass provides superior light transmission and longevity for premium operations.

After 29 years in the greenhouse industry, I have seen countless growers make costly mistakes with their covering material choices. The decision between polycarbonate and glass is not about which material is "better" – it is about which material fits your specific situation perfectly.

Core Performance Comparison: Light Transmission, Insulation, Impact Resistance, and Weight Explained?

Light transmission rates can make or break your crop yields. Most growers focus only on this single factor when choosing greenhouse coverings.

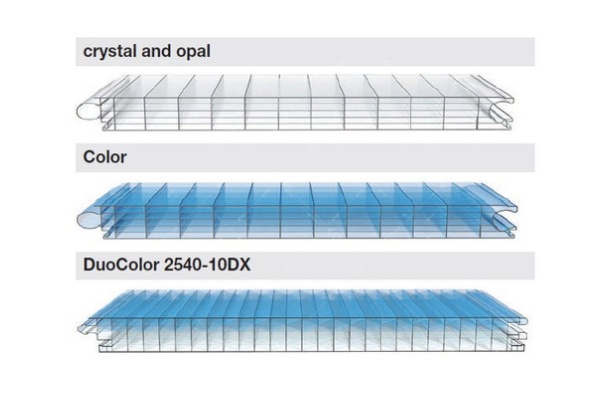

Glass greenhouses typically achieve 90-95% light transmission, while polycarbonate panels range from 80-90% depending on thickness and quality. However, polycarbonate provides better light diffusion, reducing plant stress and creating more uniform growing conditions.

The performance differences between these materials go far beyond simple light transmission numbers. During my work with commercial operations across Southeast Asia and the Middle East, I have measured actual performance data that reveals the complete picture.

Glass excels in light transmission because of its crystal-clear surface. Single-pane glass allows nearly all visible light to pass through without distortion. This makes glass ideal for crops that require maximum light intensity, such as tomatoes and cucumbers in northern climates. However, this same clarity can create hot spots and uneven light distribution inside the greenhouse.

Polycarbonate panels work differently. The material naturally diffuses incoming light, spreading it more evenly throughout the growing space. This diffusion effect reduces shadows and creates better light penetration to lower plant leaves. For leafy greens and herbs, this uniform light distribution often produces better results than the intense direct light from glass.

Performance Comparison Table

| Property | Glass | Polycarbonate |

|---|---|---|

| Light Transmission | 90-95% | 80-90% |

| Insulation Value | Poor (R-1) | Excellent (R-2.5 to R-4) |

| Impact Resistance | Low | 200x stronger |

| Weight per m² | 25-30 kg | 3-5 kg |

| Thermal Expansion | Minimal | Moderate |

| UV Protection | None | Built-in |

Insulation performance creates the biggest operational cost differences. Glass greenhouses lose heat rapidly through single-pane surfaces. During winter months in Central Asia, I have seen heating costs triple compared to polycarbonate structures. The air gaps in twin-wall polycarbonate create natural insulation barriers that maintain consistent internal temperatures.

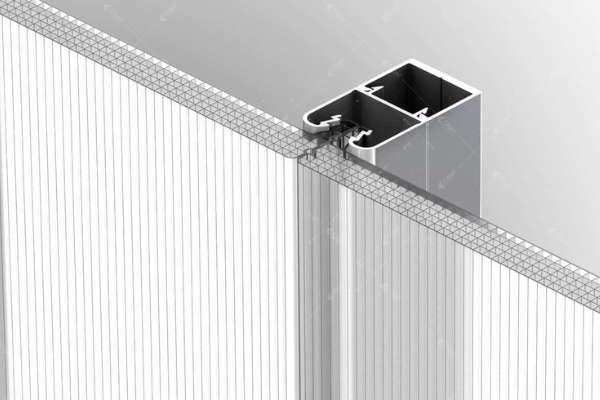

Impact resistance matters more than most growers realize. Hailstorms, falling branches, and maintenance accidents can shatter glass panels instantly. Replacing broken glass requires immediate action to protect crops from weather exposure. Polycarbonate panels can withstand impacts that would destroy glass completely. This durability translates to lower insurance costs and reduced emergency repairs.

Weight considerations affect your entire greenhouse structure. Glass requires heavy-duty framing systems with closely spaced supports. The additional steel framework increases construction costs significantly. Polycarbonate panels allow lighter frame designs with wider spacing between supports. This weight difference becomes critical in areas with snow loads or seismic activity.

Cost-Benefit Analysis: Initial Investment, Installation Difficulty, Maintenance, and ROI?

Initial costs tell only part of the financial story. Many growers choose based on upfront prices without calculating long-term expenses.

Glass greenhouses typically cost 30-40% more initially but may offer better ROI for premium crops. Polycarbonate systems provide faster payback periods through reduced heating costs and easier installation, making them ideal for cost-conscious operations.

The real financial picture emerges when you examine total cost of ownership over 10-15 years. My experience with commercial installations reveals significant differences in both obvious and hidden costs.

Initial investment differences start with material costs. High-quality glass panels cost approximately $15-25 per square meter, while equivalent polycarbonate panels range from $12-20 per square meter. However, glass requires substantially more structural support. The additional steel framing, concrete foundations, and reinforced connections add 25-35% to the total structure cost.

Installation complexity creates major cost variations. Glass panels require skilled glaziers and specialized equipment for safe handling. Each panel must be individually fitted and sealed. Weather delays are common because glass installation cannot proceed during windy conditions. Polycarbonate installation moves much faster with standard construction crews. The lightweight panels allow installation in various weather conditions, reducing project delays.

Total Cost Breakdown (per 1000m² greenhouse)

Glass Greenhouse:

- Materials: $18,000-25,000

- Structure: $35,000-45,000

- Installation: $12,000-18,000

- Total Initial: $65,000-88,000

Polycarbonate Greenhouse:

- Materials: $15,000-20,000

- Structure: $25,000-35,000

- Installation: $8,000-12,000

- Total Initial: $48,000-67,000

Operating costs create the biggest long-term differences. Heating expenses in glass greenhouses can be 40-60% higher than polycarbonate structures. For a 1000m² greenhouse in a temperate climate, this difference amounts to $3,000-5,000 annually. Over a 10-year period, the energy savings from polycarbonate often exceed the initial cost difference.

Maintenance requirements vary dramatically between materials. Glass panels need regular cleaning to maintain light transmission. Professional cleaning services charge $0.50-1.00 per square meter monthly. Broken panels require immediate replacement to prevent crop damage. Polycarbonate panels clean easily with standard equipment and rarely break from normal impacts.

Return on investment calculations must include crop quality premiums. Premium vegetable operations using glass greenhouses often achieve 10-15% higher prices for superior product quality. The enhanced light transmission and professional appearance of glass structures appeal to high-end buyers. For commodity crops, these premiums may not justify the additional costs.

Insurance costs reflect risk differences between materials. Glass greenhouses typically carry 20-30% higher premiums due to breakage risks and higher replacement values. Some insurance companies offer discounts for impact-resistant polycarbonate installations, particularly in hail-prone regions.

Matching Climate and Crop Needs: When to Choose Polycarbonate vs. When Glass is Better?

Climate conditions determine which covering material will perform best in your location. Wrong choices lead to crop failures and excessive operating costs.

Hot climates favor polycarbonate for better insulation and cooling efficiency, while temperate regions with high-value crops benefit from glass’s superior light transmission. Desert regions require impact resistance against sandstorms, making polycarbonate the practical choice.

My work across different climate zones has revealed clear patterns in material performance. Each region presents unique challenges that favor specific covering materials.

Hot climate applications in Southeast Asia and the Middle East create extreme thermal stress on greenhouse coverings. Temperatures often exceed 45°C outside, creating massive temperature differentials between day and night. Glass expands and contracts significantly, stressing sealing systems and creating air leaks. The poor insulation properties of glass make cooling systems work harder, increasing energy costs substantially.

Polycarbonate performs exceptionally well in hot climates. The material’s thermal expansion is manageable with proper installation techniques. The insulation properties reduce heat gain during the day and prevent rapid heat loss at night. This thermal stability creates better growing conditions for heat-sensitive crops like lettuce and herbs.

Desert environments present additional challenges beyond temperature. Sandstorms can pit and scratch glass surfaces, reducing light transmission over time. The abrasive particles also clog ventilation systems more quickly in glass houses due to the turbulent airflow patterns. Polycarbonate’s impact resistance and smooth surface design handle sandborne particles much better.

Climate-Specific Recommendations

Hot Humid Climates (Southeast Asia):

- Polycarbonate preferred for insulation benefits

- Better condensation management

- Reduced cooling costs

- Faster installation during dry seasons

Arid Desert Climates (Middle East):

- Polycarbonate essential for sandstorm resistance

- Superior thermal performance in extreme heat

- Lower maintenance requirements

- Better structural flexibility

Temperate Climates (Europe/North America):

- Glass suitable for premium operations

- Maximum light transmission for winter growing

- Professional appearance for retail operations

- Higher crop quality potential

Cold Climates (Northern Regions):

- Polycarbonate strongly recommended

- Massive heating cost savings

- Better snow load handling

- Reduced ice damage risks

Crop requirements create additional decision factors. High-light crops like tomatoes and peppers benefit from glass’s superior light transmission, especially during winter months. These crops can justify the higher operating costs through premium pricing and extended growing seasons.

Leafy greens and herbs often perform better under polycarbonate’s diffused lighting. The uniform light distribution reduces tip burn and creates more consistent growth patterns. For hydroponic operations growing multiple crop cycles annually, the environmental control benefits of polycarbonate often outweigh the light transmission advantages of glass.

Specialty crops require specific considerations. Orchid growers prefer glass for its clarity and professional appearance. Cannabis cultivation often uses polycarbonate for better environmental control and security considerations. Cut flower operations choose based on local market preferences and climate conditions.

FAQs and Expert Advice: Summarizing the Pros and Cons of Glass and PC Greenhouses?

Common questions reveal the real concerns growers face when choosing greenhouse coverings. These decisions impact operations for decades.

Glass offers unmatched light transmission and longevity but requires higher investment and maintenance. Polycarbonate provides superior insulation and durability at lower costs but may need replacement sooner. Choose based on your climate, crops, and budget priorities.

After thousands of greenhouse consultations, the same questions arise repeatedly. Growers want practical answers based on real-world performance data rather than marketing claims.

The most common question concerns longevity differences. Glass panels can last 30+ years with proper maintenance, while polycarbonate typically requires replacement after 10-15 years. However, this comparison ignores the total system costs. Glass greenhouses need more frequent seal replacements, structural repairs, and energy system upgrades. When you calculate actual useful life including all maintenance requirements, the gap narrows significantly.

Light transmission degradation worries many growers. Glass maintains its clarity indefinitely with regular cleaning. Polycarbonate can yellow slightly over time, especially in high-UV environments. Modern UV-stabilized polycarbonate resists this degradation much better than older formulations. For most commercial applications, the light loss is negligible compared to other factors affecting crop yields.

Comprehensive Pros and Cons Summary

Glass Greenhouse Advantages:

- Maximum light transmission (90-95%)

- Unlimited lifespan with maintenance

- Professional appearance

- No light degradation over time

- Easy cleaning and maintenance

- Premium crop quality potential

Glass Greenhouse Disadvantages:

- High initial investment costs

- Poor insulation properties

- Fragile and easily damaged

- Heavy structural requirements

- Complex installation process

- High heating/cooling costs

Polycarbonate Greenhouse Advantages:

- Excellent insulation (R-2.5 to R-4)

- Impact resistant (200x stronger than glass)

- Lightweight and easy to install

- Lower total system costs

- Better light diffusion

- UV protection included

Polycarbonate Greenhouse Disadvantages:

- Slightly lower light transmission

- Limited lifespan (10-15 years)

- Possible yellowing over time

- Thermal expansion considerations

- Less prestigious appearance

- Cleaning requires more care

The choice between materials often comes down to operational philosophy. Growers focused on maximum crop quality and long-term operations lean toward glass systems. Operations prioritizing cost efficiency and rapid expansion prefer polycarbonate solutions.

Regional preferences also influence decisions. European growers traditionally favor glass for its heritage and performance in temperate climates. Asian operations increasingly choose polycarbonate for its practical benefits in challenging climates. American growers split based on crop types and local conditions.

My recommendation process always starts with three key questions: What crops will you grow? What is your local climate? What is your budget for total system costs? The answers to these questions determine the optimal covering material more than any single performance characteristic.

For new growers entering commercial production, polycarbonate offers a lower-risk entry point with good performance across various applications. Experienced operations with established markets and premium positioning may justify glass investments for specific competitive advantages.

Conclusion

Choose your greenhouse covering based on climate conditions, crop requirements, and long-term financial goals rather than initial costs alone.