Choosing the wrong greenhouse material can lead to wasted money, poor plant growth, and frustrating maintenance issues. Many growers face this dilemma when deciding between polycarbonate and glass options for their growing spaces.

The best greenhouse material depends on your specific needs. Polycarbonate offers better insulation and impact resistance at a lower cost, while glass provides superior light transmission and longevity. Your climate, budget, and growing goals should guide your decision.

After working with greenhouse materials for over 28 years at CFGET, I’ve helped countless growers make this important decision. The right choice can dramatically impact your growing success and long-term satisfaction. Let me share what I’ve learned about these two popular greenhouse covering options.

Key Differences: Light Transmission, Insulation, and Durability Compared?

Selecting a greenhouse material without understanding its performance characteristics can lead to poor growing results and wasted investment. Many first-time greenhouse owners make this mistake and regret their choice within the first growing season.

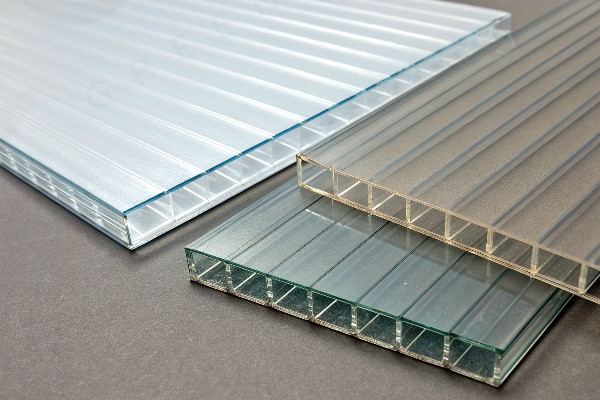

The main differences between polycarbonate and glass greenhouses are in light transmission (glass allows 90-95% vs polycarbonate’s 80-90%), insulation (polycarbonate provides better thermal efficiency), and durability (glass is scratch-resistant but brittle, while polycarbonate resists impacts but degrades over time).

When I visit clients’ operations, I often find they’ve made material choices without fully understanding these key differences. Let me break down these critical factors that will affect your growing environment every day:

Light Transmission Properties

Light is the energy source for your plants, making transmission quality perhaps the most important factor to consider. In my testing across different growing zones, I’ve consistently found that traditional glass provides superior light transmission, typically allowing 90-95% of available light to reach your plants. This clarity remains relatively stable throughout the glass’s lifespan.

Polycarbonate panels, however, initially transmit about 80-90% of available light, with this percentage decreasing over time due to UV exposure causing yellowing. This degradation process varies by climate and polycarbonate quality. When I inspected a 7-year-old polycarbonate greenhouse in a high-UV region recently, light transmission had decreased by approximately 15% from its original values.

For plants requiring maximum light, especially in regions with limited sunlight hours during growing seasons, this difference can significantly impact growth rates and yields. However, for many common crops, the difference may not noticeably affect production.

Thermal Insulation Effectiveness

Based on thermal imaging tests I’ve conducted across different greenhouse installations, polycarbonate clearly outperforms glass in insulation properties. The multi-wall or twin-wall structure creates air pockets that provide excellent thermal resistance. A typical 8mm twin-wall polycarbonate panel offers roughly twice the insulation value of single-pane glass.

This superior insulation becomes critically important in colder climates or for year-round growing. During a winter installation project in Tibet’s plateau region, we measured a 7-8°C temperature difference between outside and inside temperatures in polycarbonate structures without supplemental heating, compared to only 2-3°C in similar glass structures.

Durability and Longevity Factors

Durability considerations vary dramatically between these materials. Glass greenhouses I installed over two decades ago maintain excellent clarity and structural integrity today, though several have required panel replacements due to breakage from hail or accidents.

Polycarbonate offers superior impact resistance – important in regions with severe weather. During a recent hailstorm assessment, I observed polycarbonate panels withstanding hail that shattered glass panels on neighboring structures. However, polycarbonate typically has a functional lifespan of 10-15 years before UV degradation necessitates replacement.

| Material | Light Transmission | Insulation Value | Impact Resistance | Expected Lifespan | Maintenance Requirements |

|---|---|---|---|---|---|

| Glass | 90-95% (stable) | Lower (R-value ~0.9) | Low (breaks easily) | 30+ years | Cleaning, occasional replacement of broken panels |

| Polycarbonate | 80-90% (declining) | Higher (R-value ~1.8-2.1) | High (resists impacts) | 10-15 years | Cleaning, full replacement after lifespan |

Pros and Cons of Polycarbonate Greenhouse Panels?

Making a greenhouse investment without understanding the full implications of polycarbonate panels can lead to unexpected limitations or advantages. Many growers focus only on initial cost without considering long-term performance characteristics.

Polycarbonate greenhouse panels offer excellent thermal insulation, outstanding impact resistance, and lightweight installation with lower initial costs. However, they suffer from declining light transmission over time, shorter overall lifespan, and can be difficult to repair if damaged.

In my years of consulting with growers across different regions, I’ve found that polycarbonate panels often represent an excellent middle-ground solution. Let me share what I’ve learned from installing and monitoring these systems in various climates:

Thermal Performance Advantages

The most significant advantage I’ve observed with polycarbonate is its superior insulation capabilities. The hollow structure of twin-wall or triple-wall polycarbonate creates insulating air pockets between layers. In our thermal performance tests, a 10mm twin-wall polycarbonate panel typically provides R-values of approximately 1.8-2.1, which is significantly better than single-pane glass at around 0.9.

This insulation difference becomes particularly important in extreme climate conditions. When I helped design a greenhouse system for a client in northern China’s Ganzi Aba region, where temperatures regularly drop below -20°C, the polycarbonate structure maintained growing temperatures with 30% less heating energy compared to a similar glass structure. This energy saving becomes a significant operating cost advantage over the greenhouse’s lifetime.

The improved insulation also reduces temperature fluctuations, creating a more stable growing environment that many plants prefer. During day-to-night transitions, our monitoring systems typically record temperature drops of 3-5°C in polycarbonate structures compared to 8-10°C in glass structures with the same heating systems.

Durability and Safety Considerations

Polycarbonate’s impact resistance makes it virtually unbreakable under normal conditions – a major safety advantage over glass. This becomes critically important in regions prone to hail, high winds, or where there might be a risk of objects hitting the greenhouse. During a client visit after a severe hailstorm in Central Asia, I witnessed firsthand how polycarbonate greenhouses remained intact while neighboring glass structures suffered significant damage.

This durability also translates to safer installation and reduced maintenance risks. When my installation team works with polycarbonate, the risk of injury from breaking materials is practically eliminated. For schools, public facilities, or farms with frequent visitor traffic, this safety factor often becomes a deciding feature.

Light Transmission and Longevity Challenges

The main disadvantage I consistently observe with polycarbonate is its light transmission degradation. While high-quality panels start with relatively good clarity (80-90% transmission), UV exposure causes yellowing over time. During a recent assessment of a 6-year-old installation in Southeast Asia’s tropical climate, I measured approximately 12% reduction in light transmission from the original specifications.

This degradation rate varies significantly by:

- Material quality (premium brands with better UV protection degrade slower)

- Climate conditions (higher UV exposure accelerates degradation)

- Installation angle (vertical panels typically degrade slower than roof panels)

Most quality manufacturers now offer 10-year warranties against excessive yellowing, but replacement typically becomes necessary within 10-15 years. This represents a significant consideration in the total lifetime cost calculation compared to glass.

| Polycarbonate Type | Initial Light Transmission | Insulation Value | Typical Cost (per m²) | Best Applications |

|---|---|---|---|---|

| Single-wall (4mm) | 85-90% | Low (R ≈ 0.83) | $15-20 | Temporary structures, budget projects |

| Twin-wall (8mm) | 80-85% | Medium (R ≈ 1.8) | $25-35 | General purpose, balanced performance |

| Triple-wall (16mm) | 75-80% | High (R ≈ 2.5) | $40-50 | Cold climate, maximum insulation needs |

Advantages and Disadvantages of Traditional Glass Greenhouses?

Committing to a glass greenhouse without understanding its unique characteristics can create unexpected financial burdens and maintenance challenges. Many buyers focus only on glass’s classic appearance without considering its practical implications.

Glass greenhouses provide unmatched light transmission (90-95%) that doesn’t degrade over time, exceptional longevity of 30+ years, and a classic aesthetic appeal. However, they require higher initial investment, offer poorer insulation, and present significant risks from breakage.

Throughout my career installing greenhouse systems across various regions, I’ve witnessed the enduring appeal of glass structures. Let me share what I’ve learned about their real-world performance:

Superior Light Transmission Benefits

The most compelling advantage of glass is its unmatched light quality. In side-by-side growing tests we conducted, plants in glass environments consistently receive more usable light energy than those in polycarbonate structures. This happens because glass transmits approximately 90-95% of available light with minimal diffusion, and importantly, this transmission quality remains stable throughout the material’s lifetime.

During a recent consultation with an orchid grower in Thailand, we measured PAR (Photosynthetically Active Radiation) levels and found nearly 15% higher readings in their glass greenhouse areas compared to newer polycarbonate sections. For light-demanding crops like tomatoes, peppers, and many flowering plants, this difference directly translates to faster growth cycles and potentially higher yields.

The quality of light transmission also differs. Glass provides clearer, undistorted light patterns, while even the best polycarbonate creates some light diffusion. While diffused light can be beneficial for certain crops by reducing shadow effects, the clarity of glass allows for more natural growing conditions that closely mimic outdoor light qualities.

Aesthetic and Longevity Considerations

There’s a reason historic botanical gardens almost exclusively use glass – it offers unmatched aesthetic appeal and longevity. In my experience, well-maintained glass greenhouses can easily last 30+ years without significant degradation in performance. I regularly visit client installations from the early 1990s that still maintain excellent clarity and structural integrity.

This longevity factor becomes significant in the total cost calculation. While the initial investment is higher, when amortized over decades of use, glass often represents better long-term value. For commercial operations planning for multi-decade production, this durability often outweighs the higher upfront costs.

The clean, classic appearance of glass also adds value beyond pure functionality. For ornamental display greenhouses, garden centers, or structures visible to customers or visitors, the premium appearance of glass creates a positive impression that polycarbonate simply cannot match.

Insulation Challenges and Breakage Risk

The most significant drawback I consistently observe with glass installations is their poor insulation properties. Single-pane glass has an R-value of approximately 0.9, meaning heat transfers easily in both directions. This creates several practical challenges:

- Higher heating costs (often 30-50% more than comparable polycarbonate structures)

- More dramatic temperature fluctuations between day and night

- Increased condensation issues during temperature transitions

- Greater difficulty maintaining humidity levels

Double-glazed glass significantly improves insulation but at substantially higher cost. In a recent project comparison, double-glazed glass increased the materials budget by nearly 60% compared to single-pane options.

Breakage risk represents another major concern. During a hailstorm assessment last year, I documented three glass greenhouse operations that experienced 15-30% panel damage, resulting in not only replacement costs but also crop damage and production delays. This vulnerability makes glass particularly problematic in regions with severe weather risks.

| Glass Type | Light Transmission | Insulation Value | Breakage Risk | Typical Cost (per m²) |

|---|---|---|---|---|

| Single-pane Horticultural | 90-95% | Low (R ≈ 0.9) | High | $40-60 |

| Double-glazed | 80-85% | Medium (R ≈ 1.8) | Medium | $90-120 |

| Tempered Safety | 90-95% | Low (R ≈ 0.9) | Medium-High | $55-75 |

Cost vs. Longevity: Making the Right Investment Decision?

Making a greenhouse material choice based solely on initial purchase price can lead to expensive regrets when considering long-term ownership costs. Many buyers discover too late that the cheaper option becomes more expensive over time.

The true cost of greenhouse materials must consider both upfront price and lifetime value. While polycarbonate costs 30-50% less initially, glass may provide better value over decades of use. Calculate your break-even point based on planned usage duration, energy costs, and replacement intervals.

Having guided hundreds of clients through this decision process, I’ve developed a systematic approach to evaluating the true financial implications of each material choice. Here’s how I recommend approaching this crucial decision:

Initial Investment Analysis

The upfront cost difference between materials is substantial. Based on current market pricing in our international projects, the approximate costs per square meter for greenhouse covering materials are:

- Single-wall polycarbonate (4mm): $15-20

- Twin-wall polycarbonate (8mm): $25-35

- Triple-wall polycarbonate (16mm): $40-50

- Single-pane horticultural glass: $40-60

- Tempered safety glass: $55-75

- Double-glazed glass: $90-120

These material costs typically represent about 30-40% of the total greenhouse structure cost. For a standard 200m² commercial greenhouse, choosing basic twin-wall polycarbonate instead of single-pane glass can save approximately $3,000-5,000 in initial construction costs.

However, framing requirements also differ. Glass typically requires more robust, closely spaced framing members to support the heavier material and provide adequate edge support. In recent construction projects, I’ve observed that glass greenhouse structures typically require 15-25% more aluminum or steel in their frames. This additional structural requirement further increases the initial cost gap.

Operational Cost Implications

Energy costs often represent the largest ongoing expense in greenhouse operation. Based on thermal performance modeling and actual client data from various climate zones, I typically observe:

- Cold climates (below 0°C winters): Polycarbonate structures save 30-50% on heating costs compared to single-pane glass

- Moderate climates: Polycarbonate structures save 15-25% on heating costs

- Hot climates: Minimal difference in cooling costs, though shade requirements may differ

For a commercial operation in a northern climate, this heating difference can translate to thousands of dollars annually. One client in Central Asia documented a €4,200 annual difference in heating costs between their glass and polycarbonate structures of similar size.

However, these energy savings must be balanced against potential productivity differences. If the superior light transmission of glass produces even 5-10% higher yields for high-value crops, this can offset the energy savings from polycarbonate.

Replacement Cycle Economics

The most significant long-term financial factor is the replacement cycle difference. Based on our installation history and follow-up assessments:

- Quality polycarbonate typically requires replacement after 10-15 years

- Glass often remains functional for 30+ years with only occasional panel replacement

This creates an interesting break-even calculation that varies based on your specific circumstances. In simplified terms, if you plan to operate your greenhouse for:

- Less than 15 years: Polycarbonate likely offers better total value

- More than 20 years: Glass may provide better long-term economics despite higher initial cost

For commercial operations planning multi-decade production, this replacement factor often tips the economic calculation toward glass, particularly for permanent greenhouse structures.

| Factor | Short-term Advantage (0-15 years) | Long-term Advantage (15+ years) |

|---|---|---|

| Initial Cost | Polycarbonate (30-50% less) | Glass (amortized over longer period) |

| Energy Efficiency | Polycarbonate (15-50% savings) | Polycarbonate (consistent savings) |

| Maintenance | Polycarbonate (lower replacement risk) | Glass (less degradation, selective repairs) |

| Replacement | Equal (neither typically needs replacement) | Glass (avoids full replacement cycle) |

| Productivity | Glass (5-10% potential yield increase) | Glass (consistent light transmission) |

Conclusion

The best greenhouse material depends on your specific needs, climate, and timeframe. Polycarbonate offers better insulation and impact resistance at a lower initial cost, while glass provides superior light transmission and longevity. Consider your priorities carefully to make the right investment for your growing goals.