Building a greenhouse without understanding glass selection is like planting seeds in barren soil. It leads to poor growth, wasted energy, and ultimately, disappointing harvests that can derail your agricultural ambitions.

Choosing the right greenhouse glass in 2025 requires understanding key features like light transmittance, strength, and insulation. This guide provides a comprehensive overview to help you make informed decisions that enhance plant growth and sustainability.

After 29 years in the greenhouse industry, I have witnessed many growers struggle with glass selection. The wrong choice can cost thousands in energy bills and crop losses. Today, I will share insights that will help you navigate the complexities of greenhouse glass.

Key Essentials for Greenhouse Glass: Light Transmittance, Strength, and Insulation Explained?

Every successful greenhouse begins with understanding three critical properties of glass. These elements form the foundation of effective greenhouse performance and influence your overall success.

Light transmittance, structural strength, and thermal insulation are essential properties that dictate how well your greenhouse will perform. These factors directly affect plant growth, energy consumption, and maintenance costs throughout the greenhouse’s lifespan.

Understanding these essentials transforms your greenhouse from a mere structure into an efficient growing environment. Light transmittance affects how much sunlight reaches your plants. Most crops require 85-90% light transmission for optimal photosynthesis. However, some plants, like orchids, perform better with filtered light, needing only 70-80% transmission.

Structural strength is vital for protecting your investment against harsh weather conditions. Greenhouse glass must endure wind loads of up to 120 mph and snow loads of 30 pounds per square foot. I’ve seen greenhouses destroyed by hail or strong winds simply because the owners opted for cheaper, weaker glass.

Thermal insulation plays a crucial role in energy efficiency. Single-pane glass loses about 60% more heat than double-pane insulated alternatives. In colder climates, this difference can lead to hundreds of dollars in heating costs each month. The R-value indicates insulation effectiveness, with single glass rated at R-1 and double-pane options reaching R-2 to R-3.

Light Transmittance Performance Standards

| Glass Type | Light Transmission | Best Applications | Climate Suitability |

|---|---|---|---|

| Clear Tempered | 90-92% | Vegetable production | All climates |

| Diffuse Glass | 85-88% | Flower cultivation | Hot climates |

| Low-Iron Glass | 92-95% | Research facilities | Controlled environments |

| Tinted Glass | 70-80% | Shade-loving plants | Tropical regions |

The right glass choice depends on your specific crops and local climate conditions. I always recommend testing light levels before making final decisions.

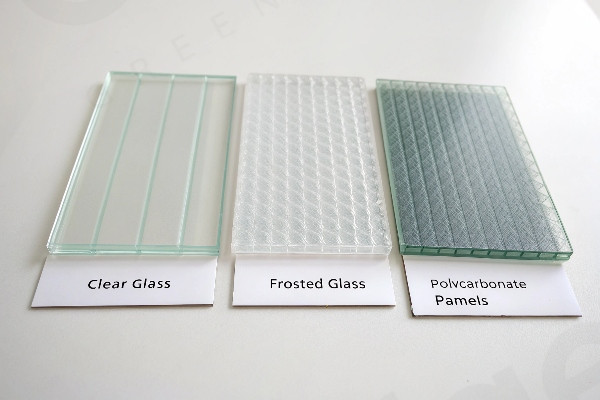

Common Greenhouse Glass Types: Comparing Tempered, Insulated, and Diffuse Glass?

Three main types of glass dominate modern greenhouse construction. Understanding their unique advantages helps you match glass properties with your greenhouse’s functional requirements.

Tempered glass provides safety and durability, insulated glass improves energy efficiency, and diffuse glass offers optimal light distribution. Each type serves specific purposes in greenhouse design, making it crucial to align your choice with your specific needs and local climate challenges.

Tempered glass has become the industry standard for good reason. This safety glass breaks into small, harmless pieces rather than dangerous shards, providing peace of mind. The tempering process makes it four times stronger than standard glass. Most agricultural greenhouses use 4-5mm tempered glass for basic protection and adequate light transmission.

Insulated glass has changed the game for energy efficiency. It consists of two or three glass panes separated by air or gas, creating a thermal barrier. The space between panes can range from 6mm to 20mm, depending on your insulation needs. Argon gas filling offers 15% better insulation compared to air-filled units.

Diffuse glass has emerged as the premium choice for specialized cultivation. This glass scatters incoming light evenly throughout the greenhouse, eliminating harsh shadows and promoting uniform growing conditions. Flower growers, in particular, report reduced plant stress and improved bloom quality when using diffuse glass.

In the early years of greenhouse development in China, we primarily used single-layer tempered glass. However, modern cultivation demands have pushed us toward specialized solutions. Today, I recommend using diffuse glass on greenhouse roofs for optimal light distribution, while side walls are best suited for insulated or laminated glass to enhance thermal efficiency.

Glass Type Performance Comparison

| Feature | Tempered | Insulated | Diffuse | Laminated |

|---|---|---|---|---|

| Safety Rating | High | Medium | High | Very High |

| Energy Efficiency | Low | High | Medium | High |

| Light Quality | Direct | Direct | Scattered | Direct |

| Cost Level | Low | High | Medium | Very High |

| Maintenance | Easy | Medium | Easy | Medium |

Each glass type serves specific purposes in greenhouse design. Your choice should align with crop requirements, climate conditions, and long-term operational goals.

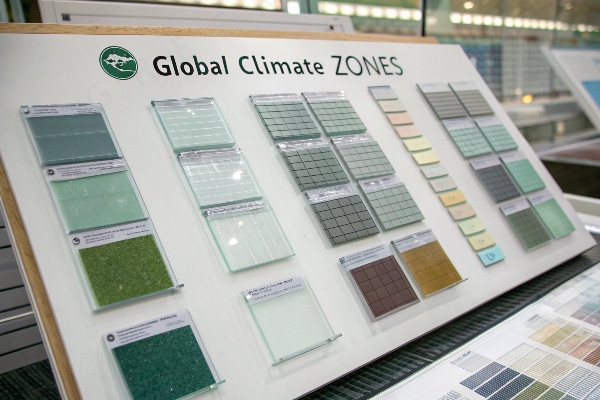

How to Choose the Right Greenhouse Glass Based on Climate and Crop Needs?

Climate conditions and crop types create the basis for smart glass selection. Different regions require specific glass properties to achieve optimal growing results and energy efficiency.

Hot climates benefit from diffuse and tinted glass options that reduce heat stress, while cold regions require insulated glass for thermal efficiency. Crop-specific needs like light intensity, UV protection, and humidity control further refine your glass selection criteria.

Clients in Southeast Asia face unique challenges due to high humidity and intense sunlight. This combination can create plant stress and energy inefficiency with the wrong glass choices. I recommend using diffuse glass on roofs to scatter harsh sunlight and reduce internal temperatures by 3-5°C, significantly saving on cooling costs during peak seasons.

In European and American markets, precision and sustainability certifications are paramount. These regions focus heavily on year-round production efficiency. Double or triple-pane insulated glass performs best for maintaining consistent internal temperatures. The initial investment pays back through reduced heating costs within just a few years.

Central Asian climates present extreme temperature variations and harsh weather conditions. Durability is the primary concern alongside thermal efficiency. Laminated insulated glass provides both safety and insulation for these demanding environments. The laminated layer helps prevent total glass failure during severe weather events.

Crop selection significantly influences glass requirements. Tomatoes and cucumbers need maximum light transmission for productive growth. Clear tempered or low-iron glass provides 90-95% light transmission. Conversely, lettuce and herbs tolerate lower light levels and benefit from diffuse glass that prevents leaf burning.

Flowering plants require specific light quality for optimal blooming. Diffuse glass creates even light distribution, improving flower quality and reducing stress. Growers of roses have reported 15-20% better bloom quality with proper diffuse glass installation.

Climate-Specific Glass Recommendations

| Climate Zone | Primary Glass Choice | Secondary Options | Key Benefits |

|---|---|---|---|

| Tropical Hot | Diffuse + Insulated sides | Tinted options | Heat reduction, UV protection |

| Temperate Cold | Double-pane insulated | Triple-pane premium | Energy efficiency, frost prevention |

| Desert Extreme | Reflective + Insulated | Low-E coatings | Temperature control, glare reduction |

| Humid Subtropical | Anti-condensation coating | Ventilated double-pane | Moisture control, mold prevention |

The right glass selection creates optimal growing conditions while minimizing operational costs. Conducting a climate analysis should be your first step in glass selection.

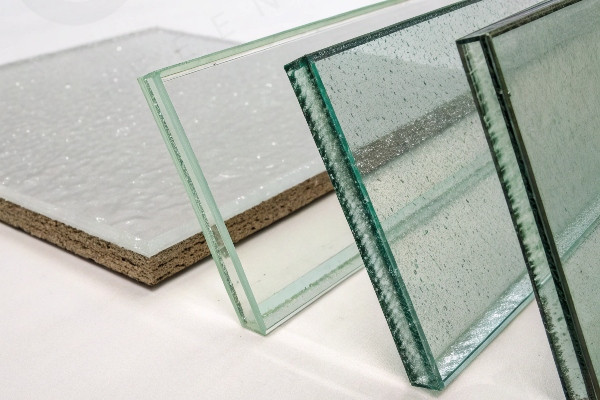

Greenhouse Glass Thickness and Durability: Ensuring Long-Term Investment Return

Glass thickness directly impacts structural integrity, energy efficiency, and maintenance costs over your greenhouse’s operational lifetime. Understanding durability factors helps you avoid costly replacements and repairs.

Standard greenhouse glass thickness ranges from 3mm to 10mm, with 4-5mm being the most common for agricultural applications. Thicker glass provides better insulation and wind resistance but increases structural load and initial costs significantly.

Choosing the right thickness depends on local building codes, wind loads, and snow loads. Areas with high wind speeds require a minimum of 5mm tempered glass. In snow-heavy regions, 6mm or thicker glass is necessary to prevent structural failure. I have witnessed many greenhouses suffer damage due to thin glass chosen to save costs.

Calculating wind resistance determines minimum thickness requirements. Glass must withstand design wind speeds without flexing beyond safe limits. The formula considers glass area, support spacing, and local wind conditions. Professional structural analysis ensures proper thickness selection for your specific location.

Thermal expansion affects glass durability, especially in extreme temperature changes. Glass expands and contracts with temperature variations. Proper edge sealing and expansion joints prevent stress fractures. Quality glazing systems accommodate thermal movement without compromising seal integrity.

Edge quality significantly impacts long-term durability. Polished edges resist stress concentration and crack initiation. Rough or damaged edges create weak points that lead to glass failure. Always specify polished edge finishing for greenhouse applications.

Surface treatments can extend glass lifespan and improve performance. Anti-reflective coatings increase light transmission by 2-3%. Easy-clean coatings reduce maintenance requirements and improve light quality over time. Low-E coatings enhance thermal efficiency without sacrificing light transmission.

Glass Thickness Selection Guide

| Application | Minimum Thickness | Recommended Thickness | Maximum Span |

|---|---|---|---|

| Small hobby greenhouse | 3mm | 4mm | 1.2m |

| Commercial vegetable | 4mm | 5mm | 1.8m |

| Large commercial | 5mm | 6mm | 2.4m |

| Extreme weather zones | 6mm | 8mm | 2.0m |

Quality glass from reputable manufacturers can last 20-25 years with proper installation and maintenance. In contrast, cheap glass may fail within 5-10 years, leading to expensive replacement costs that exceed any initial savings.

The glass industry has evolved significantly since I began in 1996. Early installations used whatever glass was locally available. Today, we specify exact properties for each application, leading to better performance and longer service life.

Investment return calculations should include energy savings, maintenance costs, and replacement frequency. High-quality glass systems typically pay for themselves within 5-7 years through reduced operational costs. The total cost of ownership favors quality over initial price savings.

Conclusion

Choosing the right greenhouse glass in 2025 balances light transmission, thermal efficiency, and structural durability with specific crops, climate, and budget requirements for optimal long-term performance.