Are you struggling with inconsistent strawberry yields and unpredictable profits? Traditional outdoor cultivation leaves your crops at the mercy of weather, pests, and seasonal limitations, threatening your business stability.

Commercial strawberry greenhouses provide controlled environments that extend growing seasons, increase yields by 30-50%, and protect crops from weather extremes and pests. They enable year-round production with precise climate control, which translates to premium pricing opportunities and higher profit margins.

After 28 years in the greenhouse industry, I’ve seen countless growers transform their operations by transitioning to controlled environment agriculture. The shift from traditional field growing to greenhouse cultivation represents more than a change in methods—it’s a complete business transformation that can dramatically improve your bottom line.

Don’t Miss:——Why Use a Greenhouse? Unlocking Year-Round Growth & Protection

Why Choose a Greenhouse for Strawberry Cultivation? Key Advantages Explained

Are unpredictable weather patterns and short growing seasons limiting your strawberry farm’s potential? Field-grown strawberries face numerous challenges that can devastate crops and profits in a single season.

Greenhouse cultivation protects strawberry plants from extreme weather, extends growing seasons to 10-12 months annually, and provides precise environmental control. This protection results in higher-quality berries with better appearance, flavor, and shelf life—commanding premium market prices.

During my visits to strawberry operations across Southeast Asia, Europe, and Central Asia, I’ve documented significant differences between traditional and greenhouse cultivation methods. One of our clients in Thailand increased their annual production by 320% after installing our climate-controlled greenhouse system.

The most significant advantages I’ve observed include climate resilience, pest management, and resource efficiency. In regions with extreme temperatures, our greenhouse systems maintain optimal growing conditions between 18-24°C during the day and 8-13°C at night—the perfect range for strawberry production. This temperature control alone can prevent the estimated 30-40% crop loss that outdoor growers experience during unusual weather events.

Water conservation is another critical benefit. Our drip irrigation systems in greenhouse environments reduce water usage by up to 75% compared to field irrigation. For a 1-hectare operation, this typically translates to savings of 3-4 million liters of water annually. The enclosed environment also creates a barrier against most pests and diseases, reducing pesticide applications by 50-80% in most operations.

Labor efficiency improves dramatically as well. With raised growing systems at comfortable working heights, pickers can harvest up to three times more berries per hour than in field operations. This efficiency is particularly valuable during peak season when labor costs and availability are critical factors for profitability.

For research facilities and premium growers, the ability to precisely control every environmental factor allows for consistent experimental conditions or targeted product characteristics. I’ve worked with university researchers who maintained identical growing conditions across multiple seasons—something impossible to achieve in field settings—allowing for breakthrough discoveries in strawberry genetics and cultivation techniques.

Don’t Miss:——What Makes a Greenhouse Ideal for Orchids? Key Features Explained

Selecting the Best Greenhouse Structure for Year-Round Strawberry Production

Finding the right greenhouse structure for your strawberry operation can feel overwhelming. With countless options available, making the wrong choice could mean wasted investment and suboptimal growing conditions for years to come.

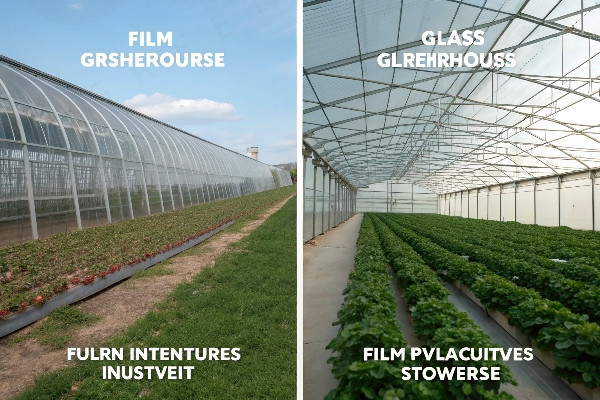

The ideal strawberry greenhouse balances light transmission, temperature control, and cost-effectiveness. Film greenhouses dominate the market (chosen by 80% of growers) due to their lower initial investment and sufficient light transmission, while glass structures offer superior durability and light conditions for premium operations.

When I consult with new strawberry greenhouse clients, I always start by analyzing their specific climate challenges and production goals. This approach has proven crucial for long-term success. For example, when working with a major producer in Malaysia, we recommended a high-roof film greenhouse with advanced ventilation systems specifically designed to manage the high humidity that was causing persistent fungal issues in their previous setup.

The structure selection process should begin with an honest assessment of your climate realities. In my experience, different regions require significantly different approaches:

For Southeast Asian clients dealing with high humidity and temperatures, we typically recommend single or double-layer film greenhouses with extensive ventilation systems, including large roll-up sides and roof vents. These designs allow for better heat management while keeping costs reasonable. One client in Vietnam reduced their crop loss from heat stress by 65% after implementing our specialized ventilation design.

European operations often benefit from more substantial structures with better insulation properties. In the Netherlands, we installed a hybrid system using glass roof panels with polycarbonate sidewalls, providing excellent light transmission during lower light winter months while maintaining better temperature control. This system extended their productive season by nearly 8 weeks annually.

For Central Asian operations facing extreme temperature fluctuations, we’ve had tremendous success with double-film inflation systems that create an insulating air pocket. This design has proven to reduce heating costs by up to 45% during harsh winters while still allowing for sufficient cooling in summer months.

Structure height is another critical factor often overlooked. I recommend a minimum 4-meter gutter height for commercial strawberry production, with 5-6 meters being ideal. This height creates a larger air volume that stabilizes temperature, reduces condensation issues, and allows space for hanging cultivation systems that maximize growing area.

The choice between film and glass ultimately depends on your specific circumstances, budget, and long-term goals. While 80% of our clients choose film options due to lower initial costs (typically 30-40% less than glass), those focusing on premium markets or operating in extreme climates often find the additional investment in glass or polycarbonate structures pays off through extended lifespan and improved growing conditions.

Essential Equipment & Technology for a Successful Strawberry Greenhouse Setup

Setting up a strawberry greenhouse with inadequate equipment leads to poor crop performance, wasted resources, and missed market opportunities. Many growers make costly mistakes by underinvesting in critical systems.

A successful commercial strawberry greenhouse requires integrated climate control systems, efficient irrigation with fertigation capabilities, appropriate growing media/systems, and monitoring technology. The right combination of these technologies creates optimal growing conditions while minimizing labor and resource inputs.

I’ve helped design hundreds of strawberry greenhouse operations, and the technology infrastructure always makes the difference between struggling and thriving businesses. During a recent project in Spain, we upgraded a traditional greenhouse with automated climate controls that paid for themselves within 14 months through yield increases and labor savings.

Climate control equipment represents the heart of any successful strawberry operation. Based on our testing across different climate zones, I recommend these specific components:

Heating systems should be designed to maintain minimum temperatures of 8°C during night hours and 18°C during active growing periods. For most commercial operations, indirect hot-water heating provides the most efficient and plant-friendly solution. In our 5,000m² demonstration facility, we installed a combination system that reduced heating costs by 38% compared to traditional forced-air heating, while providing more uniform temperatures throughout the growing area.

Ventilation requires both passive and active systems working in concert. I typically recommend automatic roof vents covering at least 20% of the roof area, combined with horizontal airflow fans (one fan per 200m²) to prevent temperature stratification and reduce disease pressure. During a recent installation in Ukraine, this combination reduced Botrytis incidence by nearly 60% compared to their previous setup.

For irrigation, strawberries respond exceptionally well to precision systems. Our testing shows that pressure-compensated drip emitters providing 2-3 liters per plant daily during peak production, delivered in multiple short cycles rather than fewer longer ones, can increase yield by 15-20% compared to less precise methods. Incorporating soil moisture sensors that trigger irrigation based on actual root zone conditions rather than timed schedules has reduced water usage by 35-40% in most installations.

Growing systems have evolved significantly during my 28 years in the industry. While traditional in-ground cultivation works, elevated systems offer substantial benefits. We’ve documented productivity increases of 25-30% using tiered systems that optimize vertical space and improve worker ergonomics. These systems typically pay for themselves within 2-3 production cycles through labor savings alone.

Cultivation troughs deserve special attention for strawberry production. Our specialized "chicken support" trough designs allow for optimal root development while preventing water pooling—a common cause of root diseases. These systems maintain an ideal balance of moisture and oxygen in the root zone, which our research shows can extend productive plant life by up to 3 months compared to standard systems.

For growing media, coco coir mixtures1 have consistently outperformed other options in our trials. A proprietary blend we’ve developed with 70% coco coir, 20% perlite, and 10% compost provides excellent drainage while maintaining sufficient water retention. This blend has shown yield increases of 12-18% compared to standard peat-based mixes, while being more environmentally sustainable.

Data monitoring technology has become increasingly accessible and valuable. At minimum, I recommend continuous monitoring of temperature, humidity, light levels, CO₂, and irrigation parameters. Modern systems allow remote monitoring via smartphone apps, enabling growers to respond quickly to changing conditions or equipment failures. One client in Belgium estimated that early alert notifications from their monitoring system prevented over €45,000 in potential crop losses during a single season.

Maximizing ROI: Cost vs. Benefit Analysis for Commercial Strawberry Greenhouses

The high initial investment in commercial strawberry greenhouse2s often deters potential growers. Many wonder if the substantial upfront costs will ever deliver sufficient returns compared to traditional field production.

A well-designed strawberry greenhouse delivers ROI through extended growing seasons (10-12 months vs. 3-5 months for field production), higher yields (typically 30-50 kg/m² annually vs. 5-8 kg/m² in fields), premium quality berries commanding higher prices, and significantly reduced crop losses from weather events and pests.

Having helped develop financial models for over 200 strawberry greenhouse operations, I’ve identified several key factors that distinguish highly profitable operations from marginally successful ones. Our data shows that optimized greenhouse operations typically achieve full return on investment within 3-5 years, compared to 7-10 years for less efficiently designed systems.

The initial investment varies significantly based on greenhouse type and technology level. In our experience, commercial strawberry greenhouses typically cost between $150-$300 per square meter for film structures and $250-$500 per square meter for glass structures, including basic equipment. This means a 1-hectare operation might require $1.5-$5 million in initial investment.

However, this investment creates tremendous production advantages. Field production typically yields 5-8 kg/m² annually during a 3-5 month season, while our greenhouse systems consistently produce 30-50 kg/m² over 10-12 months. At average wholesale prices of $3-5 per kilogram (depending on season and market), this translates to potential annual revenue of $90-250 per square meter in greenhouse production compared to $15-40 in field production.

Operating costs increase with greenhouse production, primarily in areas of energy, labor, and system maintenance. Energy typically accounts for 15-25% of operating expenses, though this varies dramatically by climate zone. In cold regions like Central Asia, we’ve implemented energy curtains and double-inflation film systems that reduce heating costs by up to 45%. In tropical regions, advanced ventilation designs have reduced cooling costs by 30-35%.

Labor represents another significant cost difference. While greenhouse production requires more consistent year-round labor than seasonal field production, the efficiency gains are substantial. Our time-motion studies show workers can harvest 12-15 kg per hour in well-designed greenhouse systems compared to 4-6 kg in field conditions. When factoring in the higher quality and reduced sorting/culling needs, labor costs per marketable kilogram are typically 25-30% lower in greenhouse environments.

Consumables represent another cost category where greenhouses offer advantages. While the precision fertigation systems in greenhouses require careful management, they typically reduce fertilizer usage by 30-40% compared to field applications. Pesticide applications drop even more dramatically, with most of our customers reporting 60-80% reductions in both quantity and frequency of applications, which benefits both the bottom line and worker safety.

The financial model becomes even more favorable when considering risk reduction. Our clients’ data shows that well-managed greenhouse operations typically experience production fluctuations of ±10-15% annually, compared to field operations that commonly see ±40-60% variations due to weather, pest pressure, and other environmental factors. This stability allows for more reliable supply contracts, better labor planning, and more predictable cash flow.

For clients concerned about construction costs, I often recommend a phased approach. Starting with 2,000-5,000 square meters allows for operational learning while generating revenue that can fund future expansions. One of our most successful clients in Turkey began with a 3,000 square meter pilot project that generated sufficient profits within two years to finance a 2-hectare expansion without additional outside capital.

Quality premiums provide another significant financial advantage. In direct market comparisons, greenhouse-grown strawberries typically command price premiums of 25-40% over field-grown counterparts due to better appearance, longer shelf life, and more consistent flavor profiles. For operations with direct market access, these premiums can transform marginally profitable ventures into highly lucrative businesses.

Conclusion

Commercial strawberry greenhouses offer an unparalleled opportunity to increase yields, extend growing seasons, and boost profits while reducing environmental impact. By carefully selecting appropriate structures and technologies matched to your specific conditions, you can transform your strawberry business into a year-round, high-efficiency operation.