Choosing the wrong greenhouse covering can cost you thousands in crop losses and energy bills. Many growers struggle with this decision daily. The right material makes all the difference.

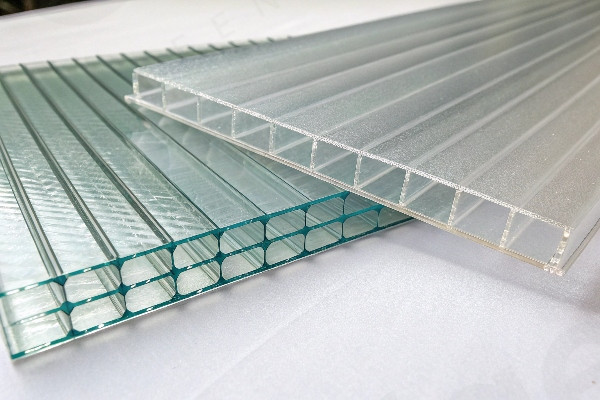

Polycarbonate and glass greenhouses differ primarily in light transmission, weight, insulation, and cost. Glass offers 90% light transmission but weighs more, while polycarbonate provides better insulation and easier installation despite slightly lower light transmission at 80-85%.

After 29 years in the greenhouse industry, I have seen countless growers make this choice. The decision impacts everything from your initial investment to daily operations. Let me share what I have learned from working with clients across different climates and growing conditions.

Light Transmission: Which is higher, and is it affected by anti-drip features?

Light transmission directly affects your crop yields and energy costs. Every percentage point matters when you are growing high-value crops. The difference can impact your bottom line significantly.

Glass greenhouses typically achieve 90% light transmission, while polycarbonate panels provide 80-85%. Anti-drip coatings on polycarbonate reduce transmission by 2-3%, but glass condensation can block up to 10% of light without proper ventilation systems.

How Light Transmission Affects Your Crops

Glass has always been the gold standard for light transmission. When I visit our clients in the Netherlands, their glass greenhouses let in maximum light for tomato and cucumber production. The clear surface allows nearly all visible light to pass through. However, this advantage comes with challenges.

Polycarbonate panels have a different story. The twin-wall or multi-wall structure scatters light, which can actually benefit some crops. This diffused light reaches plant leaves more evenly. I remember working with a lettuce grower in California who switched from glass to polycarbonate. His plants showed more uniform growth because the scattered light eliminated harsh shadows.

The anti-drip feature changes everything. Standard polycarbonate panels collect condensation that drips onto plants. This causes disease and plant stress. Anti-drip coatings solve this problem but reduce light transmission by 2-3%. Most commercial growers accept this trade-off because healthy plants matter more than slightly higher light levels.

Glass faces its own condensation challenges. Without proper ventilation, water droplets form on the inner surface. These droplets can block 10% or more of incoming light. I have seen growers lose significant yields because they underestimated this effect. The solution requires constant ventilation and heating, which increases energy costs.

| Material | Light Transmission | With Anti-drip | Condensation Impact |

|---|---|---|---|

| Glass | 90% | N/A | -10% without ventilation |

| Polycarbonate | 80-85% | 77-82% | Minimal with coating |

| Twin-wall PC | 80% | 77% | Controlled |

| Multi-wall PC | 75% | 72% | Excellent control |

Weight and Installation: Which is lighter and easier to install?

Installation costs and complexity can make or break your project budget. The weight difference between materials affects everything from foundation requirements to labor costs. This impacts your total investment significantly.

Polycarbonate panels weigh 6-8 times less than glass, requiring lighter structural support and reducing installation time by 30-40%. Glass needs specialized handling equipment and skilled glaziers, while polycarbonate can be installed by general construction crews.

Installation Complexity and Costs

Weight makes a huge difference in greenhouse construction. Glass panels typically weigh 2.5-3 kg per square meter, while polycarbonate weighs only 0.8-1.2 kg per square meter. This difference affects every aspect of your project.

I worked with a client in Thailand who initially wanted glass for his orchid greenhouse. The local soil conditions required expensive deep foundations to support the glass weight. When we switched to polycarbonate, the foundation costs dropped by 40%. The lighter weight meant simpler structural requirements and faster construction.

Glass installation requires specialized skills. Glaziers must handle large, fragile panels carefully. One broken panel can delay your entire project. I have seen projects where glass breakage during installation added weeks to the timeline. The replacement costs and delays frustrated growers who needed to start planting on schedule.

Polycarbonate installation is much simpler. General construction crews can handle the lightweight panels. The material bends slightly without breaking, making it forgiving during installation. Panels connect with simple gasket systems that create weather-tight seals. This flexibility reduces installation time and labor costs.

Weather conditions affect installation differently. Glass work stops during wind or rain because panels become dangerous to handle. Polycarbonate installation can continue in moderate weather conditions. This flexibility helps keep projects on schedule, especially in regions with unpredictable weather patterns.

The structural requirements differ significantly. Glass greenhouses need heavy-duty frames with closely spaced supports. Polycarbonate allows wider spacing between supports, reducing material costs. The lighter load also means smaller foundations and less concrete, further reducing costs.

Regional Installation Considerations

Different regions present unique installation challenges. In the Middle East, extreme heat makes glass handling dangerous during summer months. Workers must start early morning and stop by noon. Polycarbonate installation can continue longer because the material stays cooler to touch.

Southeast Asian clients face monsoon seasons that limit glass installation windows. The lightweight polycarbonate allows faster installation during dry periods. I helped a client in Malaysia complete his greenhouse before the rainy season started. With glass, we would have missed the deadline.

European clients often prefer glass for its appearance and performance. However, the installation requires skilled labor that costs more. The total installed cost difference between materials can reach 25-30% when you include all factors.

Insulation Performance: Which is better for winter use?

Heating costs can consume 30-40% of your operating budget in cold climates. The insulation performance of your covering material directly affects these costs. Better insulation means lower energy bills and more consistent growing conditions.

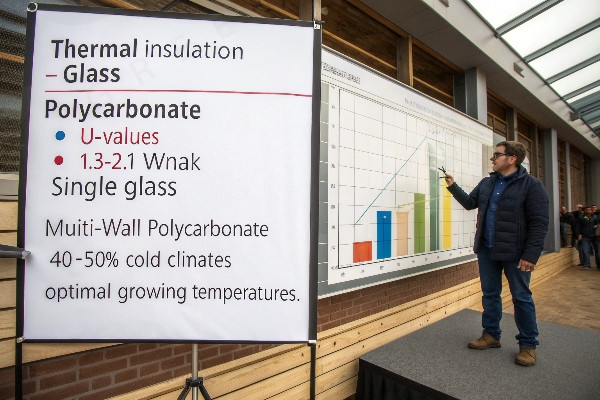

Polycarbonate provides superior insulation with U-values of 1.3-2.1 W/m²K compared to single glass at 5.7 W/m²K. Multi-wall polycarbonate can reduce heating costs by 40-50% in cold climates while maintaining optimal growing temperatures.

Understanding Thermal Performance

Insulation performance determines your heating costs and crop success in cold climates. The U-value measures how much heat passes through the material. Lower numbers mean better insulation and lower heating costs.

Single glass has a U-value of 5.7 W/m²K, making it a poor insulator. Heat escapes rapidly through glass surfaces. I worked with a tomato grower in Canada who spent over $40,000 annually heating his glass greenhouse. The high energy costs made his operation barely profitable during winter months.

Polycarbonate’s multi-wall structure creates insulating air spaces. Twin-wall polycarbonate achieves U-values around 2.1 W/m²K, while triple-wall reaches 1.3 W/m²K. This represents a 60-75% improvement over single glass. The same Canadian grower switched to triple-wall polycarbonate and cut his heating costs by half.

The air spaces in polycarbonate act like thermal barriers. Heat cannot conduct directly through the material. Instead, it must travel through air gaps that resist heat transfer. This principle works the same way as double-pane windows in your home but with even better performance.

Double glass can improve insulation performance but adds significant weight and cost. The U-value drops to about 2.8 W/m²K, which is better than single glass but still inferior to multi-wall polycarbonate. The weight increase requires stronger structures, adding to the total cost.

Real-World Energy Savings

Energy savings translate directly to profit margins. I calculated the annual heating costs for a 1000 square meter greenhouse in different climates. The results show dramatic differences between materials.

In Northern Europe, a glass greenhouse might require 150-200 kWh per square meter annually for heating. The same greenhouse with triple-wall polycarbonate needs only 80-100 kWh per square meter. At current energy prices, this saves $15,000-25,000 annually for a medium-sized operation.

The insulation benefits extend beyond heating costs. Better insulation means more stable temperatures throughout the day and night. Plants experience less stress from temperature fluctuations. This stability improves growth rates and reduces crop losses from temperature-related problems.

Cooling costs also decrease with better insulation. In hot climates, polycarbonate blocks more heat from entering the greenhouse. The insulating properties work both ways, keeping heat out during summer and in during winter. This dual benefit makes polycarbonate particularly valuable in regions with extreme temperature variations.

| Climate Zone | Glass Heating Cost | Polycarbonate Cost | Annual Savings |

|---|---|---|---|

| Northern Europe | $25,000 | $12,500 | $12,500 |

| Central Europe | $18,000 | $9,000 | $9,000 |

| North America | $20,000 | $10,000 | $10,000 |

| Cold Asia | $22,000 | $11,000 | $11,000 |

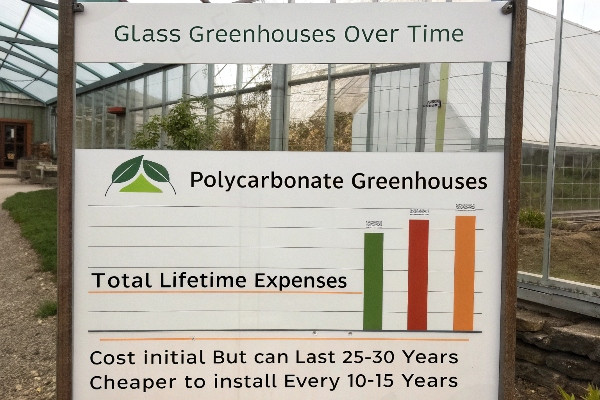

Cost and Lifespan: How do initial investment and long-term maintenance differ?

Total cost of ownership includes initial investment, maintenance, and replacement costs over the greenhouse lifespan. The cheapest option upfront might cost more over time. Understanding these long-term costs helps you make the right financial decision.

Glass greenhouses cost 40-60% more initially but can last 25-30 years with proper maintenance. Polycarbonate costs less upfront but requires replacement every 10-15 years. Total lifetime costs often favor polycarbonate due to lower installation and energy expenses.

Initial Investment Breakdown

The upfront cost difference between materials affects your project financing and cash flow. Glass greenhouse systems typically cost $45-65 per square meter for materials alone. Polycarbonate systems cost $25-40 per square meter for comparable performance.

Installation costs add another layer of expense. Glass installation requires skilled glaziers who charge premium rates. The specialized equipment needed for handling large glass panels increases labor costs. Total installation can add $15-25 per square meter to your project cost.

Polycarbonate installation uses standard construction crews at lower hourly rates. The lightweight panels require no special equipment. Installation typically adds only $8-12 per square meter to your total cost. This difference can save thousands on medium to large projects.

Foundation and structural costs vary significantly between materials. Glass requires heavy-duty frames and deeper foundations to support the weight. These structural requirements can add 20-30% to your total project cost. Polycarbonate allows lighter structures that reduce foundation and framing expenses.

I helped a client in Kazakhstan compare costs for a 2000 square meter greenhouse. The glass option required $180,000 for materials, installation, and structure. The polycarbonate alternative cost $110,000 for equivalent performance. The $70,000 difference allowed him to invest in better climate control systems.

Maintenance and Replacement Costs

Maintenance requirements differ dramatically between materials. Glass panels can crack from hail, thermal stress, or impact damage. Replacing individual panels requires skilled labor and can disrupt growing operations. Each replacement panel costs $8-15 per square meter plus installation.

Polycarbonate panels resist impact damage better than glass. The flexible material can absorb impacts that would shatter glass. However, polycarbonate degrades from UV exposure over time. The material becomes brittle and loses light transmission after 10-15 years of service.

Cleaning requirements also differ between materials. Glass surfaces stay cleaner longer and are easier to wash. Polycarbonate can develop surface scratches from cleaning that reduce light transmission. However, the impact resistance means fewer emergency repairs and replacements.

I track maintenance costs for clients across different regions. Glass greenhouses average $2-4 per square meter annually for repairs and panel replacements. Polycarbonate maintenance costs only $1-2 per square meter annually but requires complete replacement every 10-15 years.

Weather-related damage creates the biggest maintenance differences. Hailstorms can destroy glass panels across entire greenhouse sections. I have seen clients lose $50,000 worth of glass in a single storm. The same storm might cause no damage to polycarbonate panels.

Long-term Financial Analysis

The total cost of ownership calculation reveals the true financial impact of your material choice. This analysis includes initial costs, maintenance, energy savings, and replacement expenses over the greenhouse lifetime.

Glass greenhouses can operate for 25-30 years with proper maintenance. The long lifespan spreads the initial investment over many years. However, higher heating costs and maintenance expenses accumulate over time. The total cost per year often exceeds the polycarbonate alternative.

Polycarbonate requires replacement every 10-15 years, creating periodic major expenses. However, the lower initial cost, reduced heating bills, and minimal maintenance often result in lower total costs. The energy savings alone can justify the material choice in cold climates.

Technology improvements favor polycarbonate over time. New formulations extend UV resistance and improve light transmission. Glass technology remains relatively static. Future polycarbonate replacements will likely perform better than current materials.

Regional factors affect the financial analysis significantly. In the Middle East, where I work with many high-end crop producers, glass often makes financial sense despite higher costs. The superior light transmission and prestige factor justify the investment for premium crops.

Southeast Asian clients typically choose polycarbonate for cost reasons. The lower initial investment allows faster project completion and earlier revenue generation. The shorter replacement cycle matches their business planning horizons better.

| Cost Factor | Glass (30 years) | Polycarbonate (30 years) |

|---|---|---|

| Initial Cost | $130,000 | $80,000 |

| Maintenance | $18,000 | $12,000 |

| Energy Costs | $450,000 | $270,000 |

| Replacements | $0 | $80,000 |

| Total Cost | $598,000 | $442,000 |

Conclusion

The choice between polycarbonate and glass depends on your specific climate, crops, and budget. Consider all factors including energy costs, maintenance, and local conditions for the best decision.