Your material choice determines profitability for the next 20 years. One wrong decision can cost you thousands in energy bills and crop losses.

Commercial greenhouse success depends on eight critical material factors: light transmission, structural costs, maintenance requirements, and thermal performance. Glass offers 90% light transmission and 25-year lifespan, while polycarbonate provides superior insulation (R-2.5) and 40% lower installation costs. Your ROI depends on matching material properties to local climate and crop requirements.

Three years ago, I helped a Dutch tomato grower switch from single glass to triple-wall polycarbonate. His heating costs dropped 35%, but he questioned the light reduction. Today, his yields increased 12% due to better temperature control and diffused lighting.

How Does Light Performance Actually Impact Your Crop Yields and Quality?

Light transmission directly affects photosynthesis efficiency and crop development. Anti-drip properties prevent disease outbreaks and maintain optimal growing conditions throughout the season.

Glass provides 90% light transmission with minimal diffusion, ideal for light-hungry crops. Polycarbonate offers 80-85% transmission with beneficial light scattering that reduces hot spots. Anti-drip coatings on both materials prevent condensation drops that can damage plants and spread diseases.

Real-World Light Transmission Analysis

Light quality matters more than quantity for many crops. Glass delivers direct, unfiltered sunlight that maximizes photosynthetic activity in light-sensitive plants. Rose growers consistently choose glass because flower quality and stem strength depend on maximum light intensity. The clear transmission preserves natural light spectrum without distortion.

Polycarbonate’s cellular structure creates beneficial light diffusion. This scattered light penetrates deeper into plant canopies, improving photosynthesis in lower leaves. Lettuce and herb growers report more uniform growth patterns under polycarbonate covers. The diffusion reduces leaf burning in high-intensity sunlight regions.

Seasonal light variations affect both materials differently. Winter light transmission becomes critical in northern climates where every photon counts. Glass maintains consistent transmission year-round, while polycarbonate may accumulate dust or condensation that reduces winter performance. Regular cleaning protocols become essential for polycarbonate installations.

Light spectrum preservation influences crop quality. Glass transmits full spectrum light without alteration, supporting natural plant development cycles. Some polycarbonate formulations filter specific wavelengths, potentially affecting flowering or fruiting in sensitive crops. Premium polycarbonate maintains better spectrum fidelity but costs significantly more.

Anti-Drip Technology and Disease Prevention

Condensation management prevents fungal diseases and crop damage. Uncontrolled water droplets create ideal conditions for botrytis, powdery mildew, and bacterial infections. Both materials offer anti-drip solutions with different mechanisms and effectiveness levels.

Glass anti-drip coatings create hydrophilic surfaces that form water sheets instead of droplets. These coatings typically last 3-5 years before requiring reapplication. The smooth water flow prevents dripping while maintaining optical clarity. Application costs range from $2-4 per square meter.

Polycarbonate anti-drip treatments penetrate the material surface during manufacturing. This permanent treatment eliminates the need for reapplication but may slightly reduce light transmission by 1-2%. The cellular structure naturally channels condensation to panel edges, reducing interior dripping.

Disease prevention benefits justify anti-drip investments. Cucumber growers report 20-30% reduction in fungal diseases with proper condensation management. The improved air circulation and reduced humidity create healthier growing environments. Crop loss prevention often pays for anti-drip treatments within one growing season.

| Material Type | Light Transmission | Anti-Drip Duration | Disease Reduction | Annual Maintenance |

|---|---|---|---|---|

| Glass Standard | 90% | N/A | Baseline | Low |

| Glass Anti-Drip | 89% | 3-5 years | 25% reduction | Reapplication needed |

| PC Standard | 82% | N/A | Baseline | Medium |

| PC Anti-Drip | 80% | Permanent | 30% reduction | None required |

What Hidden Structural Costs Could Double Your Project Budget?

Material weight dramatically affects foundation requirements, frame specifications, and installation complexity. These structural considerations often represent 30-40% of total project costs.

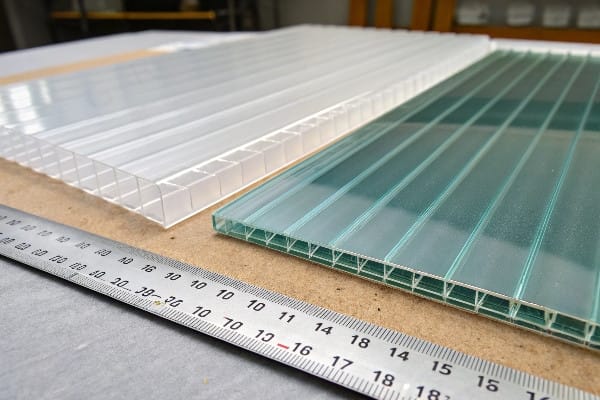

Glass requires reinforced foundations and heavy-duty aluminum profiles due to 2.5kg/m² weight. Polycarbonate’s 0.8kg/m² allows lighter structures and faster installation. Foundation costs vary by 40-60% between materials, while frame requirements differ significantly in aluminum profile specifications.

Foundation Engineering Requirements

Glass installations demand robust concrete foundations designed for higher loads. Wind uplift calculations must account for glass panel weight and surface area. Foundation depths typically increase 20-30% compared to polycarbonate installations. Concrete volume requirements often double for large commercial structures.

Soil conditions affect foundation costs differently for each material. Glass structures require deeper footings in soft soils to prevent settling. Polycarbonate’s lighter weight allows standard foundation depths in most soil conditions. Geotechnical surveys may reveal significant cost differences based on local soil characteristics.

Seismic considerations favor polycarbonate in earthquake-prone regions. The lighter structure reduces seismic forces and foundation requirements. Glass installations may require additional reinforcement and flexible connections to handle seismic movement. These upgrades can add 10-15% to structural costs.

Drainage systems must accommodate different thermal expansion rates. Glass structures require precise drainage slopes to handle thermal movement. Polycarbonate’s higher expansion coefficient demands flexible drainage connections. Poor drainage design leads to structural problems and material failure.

Aluminum Profile Specifications

Glass requires heavy-duty aluminum profiles with deeper sections and thicker walls. Standard glass greenhouse profiles measure 80-120mm depth with 3-4mm wall thickness. The glazing system demands precise tolerances and specialized gaskets. These profiles cost 40-60% more than polycarbonate equivalents.

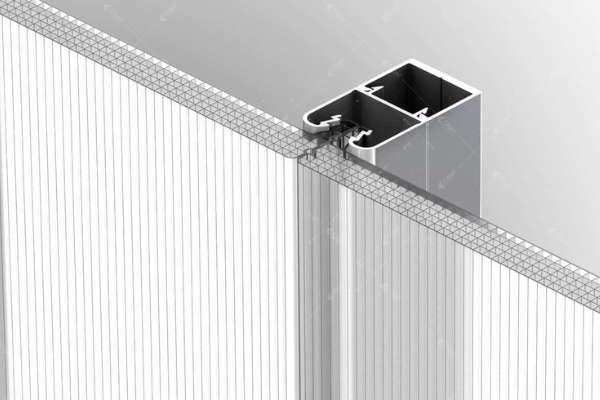

Polycarbonate installations use lighter profiles with simplified connection systems. Profile depths range from 50-80mm with 2-3mm wall thickness. The cellular panel structure distributes loads effectively, reducing profile requirements. Standard H-profiles and U-channels provide adequate support at lower costs.

Thermal bridge considerations affect energy performance. Glass installations benefit from thermal breaks in aluminum profiles to reduce heat transfer. These thermal breaks add 20-30% to profile costs but improve energy efficiency. Polycarbonate’s insulation properties make thermal breaks less critical.

Connection details influence installation speed and costs. Glass systems require precise glazing bars and weatherproof seals. Installation time increases due to careful handling and alignment requirements. Polycarbonate systems use simpler connection methods that reduce labor costs by 25-35%.

Installation Labor and Equipment

Glass installation requires specialized crews with glazing experience. Labor rates increase 30-50% for experienced glass installers. The fragile material demands careful handling and precise installation techniques. Weather sensitivity limits installation windows and may cause project delays.

Equipment requirements differ significantly between materials. Glass installations need cranes or lifting equipment for large panels. Transportation requires specialized trailers with protective systems. These equipment costs add $3-5 per square meter to installation expenses.

Polycarbonate installation uses standard construction tools and techniques. General contractors can handle most installations with basic training. The flexible material allows installation in various weather conditions. Reduced equipment needs lower installation costs substantially.

Safety considerations affect labor costs and insurance requirements. Glass installations carry higher injury risks and insurance premiums. Safety equipment and procedures add complexity and expense. Polycarbonate’s lighter weight and flexibility reduce safety concerns and associated costs.

How Do Long-Term Maintenance Costs Affect Your Investment Returns?

Maintenance requirements and replacement schedules significantly impact total ownership costs. Understanding these long-term expenses helps optimize material selection and budgeting decisions.

Glass offers 20-25 year service life with minimal maintenance but higher replacement costs. Polycarbonate provides 10-15 year lifespan with gradual performance decline and moderate replacement expenses. Maintenance protocols, repair costs, and replacement timing vary substantially between materials.

Degradation Patterns and Performance Decline

Glass maintains consistent performance throughout its service life with minimal degradation. Light transmission remains stable at 90% for decades with proper maintenance. The main concerns involve thermal stress cracking and impact damage from weather events. Quality glass installations can exceed 25-year service life with careful maintenance.

Polycarbonate experiences gradual performance decline over time. Light transmission typically decreases 1-2% annually due to UV exposure and surface weathering. Yellowing becomes noticeable after 8-12 years depending on UV protection quality. Premium panels with co-extruded UV layers maintain performance longer but cost significantly more.

Thermal cycling affects materials differently over time. Glass handles temperature variations well but may develop stress cracks at mounting points. These cracks typically appear after 15-20 years in extreme climate conditions. Polycarbonate remains flexible but may develop expansion-related problems if improperly installed.

Surface degradation impacts both materials but with different patterns. Glass surfaces remain smooth and easy to clean throughout their service life. Polycarbonate surfaces may develop micro-scratches that reduce optical clarity and increase cleaning difficulty. Professional restoration services can improve appearance but add maintenance costs.

Repair and Replacement Strategies

Panel replacement procedures vary significantly between materials. Glass replacement requires complete glazing system removal and careful handling of large panels. Specialized tools and experienced technicians are essential. Single panel replacement typically costs $20-35 per square meter including labor and materials.

Polycarbonate replacement offers simpler procedures with standard tools and general construction skills. Individual panels can be removed without affecting adjacent sections. Replacement costs range from $12-20 per square meter including materials and labor. The process can often be completed during normal maintenance windows.

Emergency repair capabilities differ substantially. Broken glass creates immediate safety hazards requiring prompt professional attention. Temporary repairs using plastic sheeting maintain basic weather protection until permanent repairs are completed. Emergency glass repair costs often double normal replacement expenses.

Polycarbonate damage rarely creates safety issues but may compromise thermal performance. Temporary repairs using tape or sealants can maintain basic functionality. Emergency repairs are typically less expensive and can be performed by facility maintenance staff.

Preventive Maintenance Programs

Cleaning requirements and schedules affect long-term appearance and performance. Glass surfaces clean easily with standard window cleaning techniques and maintain optical clarity indefinitely. Professional cleaning 2-3 times annually maintains peak performance at costs of $0.50-1.00 per square meter.

Polycarbonate requires gentler cleaning methods to avoid surface damage. Soft brushes and mild detergents prevent scratching while removing dirt and algae. Cleaning frequency may need to increase in dusty environments. Annual cleaning costs range from $0.75-1.25 per square meter with specialized techniques.

Seal maintenance becomes critical for both materials but with different requirements. Glass installations require periodic glazing compound renewal and gasket replacement. These maintenance tasks typically occur every 7-10 years at costs of $3-5 per linear meter of glazing bar.

Polycarbonate sealing systems require different maintenance approaches. End seals and H-profile connections may need renewal every 5-8 years. The cellular structure requires proper ventilation to prevent moisture accumulation. Seal maintenance costs typically range from $2-4 per linear meter.

Which Material Delivers Superior Winter Performance for Your Climate?

Thermal performance directly affects heating costs and crop productivity during cold seasons. Material choice can impact energy expenses by 30-50% in heating-intensive climates.

Glass provides minimal insulation (R-0.9) requiring higher heating inputs but offers maximum light transmission during low-light winter months. Polycarbonate delivers superior insulation (R-1.7 to R-2.5) reducing heating costs by 25-40% while providing adequate light for most crops. Climate zone and crop heat requirements determine optimal material selection.

Thermal Performance Analysis

Insulation values directly translate to heating cost differences. Single-pane glass offers R-0.9 thermal resistance, requiring maximum heating input to maintain growing temperatures. Double-glazed glass improves to R-2.0 but doubles material costs and reduces light transmission to 82%.

Polycarbonate’s cellular structure provides natural insulation without light transmission penalties. Twin-wall panels achieve R-1.7 values while maintaining 80-82% light transmission. Triple-wall versions reach R-2.5 but reduce light transmission to 75-78%. The insulation benefit often outweighs light reduction for energy-intensive crops.

Heat loss calculations reveal significant energy differences. A typical 1000 square meter greenhouse in northern climates loses 40-60% more heat through glass compared to twin-wall polycarbonate. This translates to heating cost increases of $8,000-15,000 annually depending on fuel prices and climate severity.

Thermal bridging through aluminum frames affects overall performance. Glass installations benefit from thermal breaks in glazing systems to reduce heat transfer. These thermal breaks add costs but improve energy efficiency by 10-15%. Polycarbonate’s insulation properties make thermal bridging less critical.

Crop-Specific Thermal Requirements

Heat-loving crops like tomatoes, peppers, and cucumbers benefit significantly from polycarbonate’s insulation properties. These crops require consistent temperatures above 18°C for optimal growth. The reduced heating costs often justify polycarbonate selection despite light transmission reduction.

Cool-season crops may prefer glass for maximum light availability during short winter days. Lettuce, spinach, and herbs prioritize light over thermal efficiency in many climates. The additional heating costs may be justified by improved crop quality and faster growth rates.

Flowering crops present complex thermal requirements. Roses require both adequate light and consistent temperatures for quality flower production. Many commercial rose growers choose glass despite higher heating costs to maintain flower quality and market premiums.

Seedling production facilities often select polycarbonate for thermal stability. Young plants benefit from consistent temperatures more than maximum light intensity. The reduced temperature fluctuations improve germination rates and seedling quality.

Regional Climate Considerations

Northern European climates favor polycarbonate for energy efficiency. Long heating seasons and high energy costs make insulation critical. Many Dutch and Scandinavian growers choose polycarbonate despite the greenhouse industry’s traditional preference for glass.

Mediterranean climates present different challenges. Mild winters reduce heating requirements while intense summers create cooling demands. Glass may perform better in these conditions due to superior light transmission and thermal mass effects.

Continental climates with extreme temperature swings test both materials severely. Polycarbonate’s insulation benefits help during cold periods, while glass handles temperature extremes better. Local climate data analysis helps determine optimal material selection.

Coastal regions with moderate temperatures may favor glass for light transmission benefits. The reduced heating requirements make energy efficiency less critical. Salt air exposure requires careful material selection and maintenance planning.

Economic Analysis of Thermal Performance

Energy cost analysis should span 10-15 years to capture true thermal performance benefits. Polycarbonate’s insulation advantages compound annually through reduced heating expenses. The energy savings often exceed initial material cost differences within 3-5 years.

Heating system sizing affects initial capital costs. Glass installations require larger heating systems to compensate for higher heat losses. Boiler capacity may need to increase 25-40% for glass compared to polycarbonate installations. These equipment costs add $15,000-30,000 for large commercial structures.

Carbon footprint considerations increasingly influence material selection. Polycarbonate’s energy efficiency reduces greenhouse gas emissions throughout the structure’s service life. Many growers choose polycarbonate to meet sustainability goals and carbon reduction targets.

Government incentives may favor energy-efficient materials. Some regions offer rebates or tax credits for high-performance greenhouse installations. These incentives can offset polycarbonate’s higher initial costs and improve project economics.

Conclusion

Material selection shapes your greenhouse’s profitability, energy efficiency, and crop quality for decades. Analyze your specific climate, crops, and economic priorities to make the optimal choice for long-term success.