Choosing the wrong covering material can destroy your entire harvest and waste thousands of dollars. After 28 years in greenhouse manufacturing, I’ve seen growers make costly mistakes with material selection.

The success of your greenhouse operation depends heavily on selecting the right covering material. Polycarbonate offers superior insulation and impact resistance, while glass provides maximum light transmission and durability. Your choice should align with local climate conditions, crop requirements, and long-term investment goals.

Last month, I visited a tomato grower in Thailand who switched from glass to polycarbonate panels. His energy costs dropped by 30%, but he worried about light transmission. This conversation reminded me why material selection requires deep understanding of both options.

What Makes Material Properties Critical for Your Greenhouse Success?

Your covering material directly impacts plant growth, energy consumption, and operational costs. The wrong choice can lead to poor harvests and financial losses.

Material properties determine light quality, temperature control, and structural requirements. Polycarbonate excels in insulation with R-values up to 2.5, while glass offers 90% light transmission compared to polycarbonate’s 80-85%. Impact resistance favors polycarbonate at 200 times stronger than glass.

Understanding Core Performance Characteristics

Transparency affects photosynthesis efficiency and plant development. Glass provides superior optical clarity with minimal light diffusion. Single-pane glass achieves 90% light transmission, making it ideal for light-sensitive crops like roses or high-value vegetables. However, this clarity comes with thermal challenges.

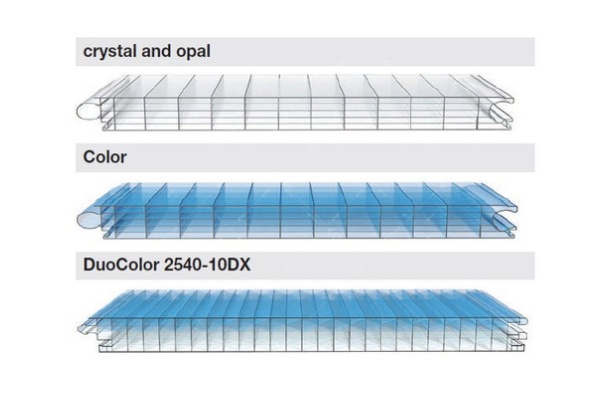

Polycarbonate panels offer different light transmission rates depending on thickness and structure. Twin-wall polycarbonate typically provides 80-82% light transmission, while triple-wall versions drop to 75-78%. The cellular structure creates light diffusion, which benefits many crops by reducing hot spots and providing more uniform light distribution.

Insulation performance varies dramatically between materials. Glass offers minimal thermal resistance with R-values around 0.9 for single-pane installations. Double-glazed glass improves to R-2.0 but increases costs significantly. Polycarbonate’s cellular structure provides natural insulation. Twin-wall panels achieve R-values of 1.7, while triple-wall versions reach R-2.5 or higher.

Weight considerations impact structural requirements and installation complexity. Glass weighs approximately 2.5 kg per square meter for 4mm thickness, requiring robust framing systems. Polycarbonate weighs only 0.8 kg per square meter for equivalent coverage, reducing structural loads and foundation requirements.

| Property | Single Glass | Double Glass | Twin-wall PC | Triple-wall PC |

|---|---|---|---|---|

| Light Transmission | 90% | 82% | 80-82% | 75-78% |

| R-Value | 0.9 | 2.0 | 1.7 | 2.5 |

| Weight (kg/m²) | 2.5 | 5.0 | 0.8 | 1.2 |

| Impact Resistance | Low | Low | High | High |

How Do Installation Requirements Affect Your Project Timeline and Budget?

Installation complexity directly impacts project costs, timeline, and long-term structural integrity. Different materials demand specific approaches and expertise levels.

Glass installations require specialized glazing systems, precise measurements, and experienced technicians. Polycarbonate offers faster installation with standard tools but needs proper sealing techniques. Frame requirements vary significantly, with glass demanding heavier structural support systems.

Frame and Structural Considerations

Glass installations demand robust aluminum profiles designed for higher loads. The glazing system requires precise tolerances and specialized gaskets. Aluminum sections must accommodate thermal expansion while maintaining weatherproof seals. Standard glass greenhouse profiles measure 60-80mm in depth with reinforced corners and drainage channels.

Polycarbonate installations use lighter aluminum systems with different sealing approaches. H-profiles and U-channels secure panels while allowing thermal movement. The cellular structure requires proper end sealing to prevent moisture infiltration and maintain insulation properties. Profile depths typically range from 40-60mm.

Installation speed favors polycarbonate significantly. A typical 1000 square meter greenhouse requires 5-7 days for polycarbonate installation versus 10-14 days for glass. The lighter weight allows smaller installation teams and reduces crane requirements. However, proper sealing techniques remain critical for long-term performance.

Cost implications extend beyond material prices. Glass installations require specialized labor, increasing hourly rates by 20-30%. Transportation costs rise due to weight and fragility concerns. Polycarbonate’s lighter weight and flexibility reduce shipping expenses and handling requirements.

Weather sensitivity affects installation scheduling. Glass installations require calm conditions and dry weather for proper sealing. Polycarbonate offers more flexibility, allowing installation during mild weather conditions. This scheduling advantage can reduce project delays in regions with unpredictable weather patterns.

What Long-Term Costs Should You Consider Beyond Initial Investment?

Maintenance requirements and material lifespan significantly impact total ownership costs. Understanding these factors helps make informed financial decisions for your greenhouse operation.

Glass offers superior longevity with minimal degradation over 20-30 years but requires careful handling and replacement of broken panels. Polycarbonate provides 10-15 year service life with gradual light transmission loss and potential yellowing. UV protection and cleaning protocols differ substantially between materials.

UV Resistance and Degradation Patterns

Glass provides excellent UV stability with minimal degradation over decades. Quality glass maintains light transmission and structural integrity throughout its service life. The main concern involves thermal stress cracking in extreme temperature variations or impact damage from hail or debris.

Polycarbonate UV resistance depends heavily on protective coatings and material quality. Premium panels include co-extruded UV protection layers that prevent yellowing and maintain light transmission. Standard panels without UV protection can yellow significantly within 3-5 years, reducing light transmission by 10-15%.

Cleaning requirements differ between materials. Glass surfaces clean easily with standard techniques and maintain optical clarity. Polycarbonate requires gentler cleaning methods to avoid scratching. Abrasive cleaners or high-pressure washing can damage the surface, creating light scattering and reducing transparency.

Scratch resistance favors glass significantly. Minor scratches on glass rarely affect light transmission or appearance. Polycarbonate scratches more easily and may require professional polishing or panel replacement. Deep scratches cannot be repaired effectively, necessitating panel replacement.

Thermal cycling affects both materials differently. Glass handles temperature variations well but may develop stress cracks at mounting points. Polycarbonate expands and contracts more than glass, requiring proper installation techniques to prevent panel buckling or seal failure.

Replacement and Repair Considerations

Panel replacement procedures vary considerably. Glass replacement requires complete removal of glazing systems and careful handling of large panels. Specialized tools and experienced technicians are essential. Single panel replacement typically costs $15-25 per square meter including labor.

Polycarbonate panel replacement offers simpler procedures. Individual panels can be removed and replaced without affecting adjacent sections. Standard tools suffice for most installations. Replacement costs range from $8-15 per square meter including materials and labor.

Emergency repairs present different challenges. Broken glass creates immediate safety hazards and requires prompt professional attention. Temporary repairs using plastic sheeting can maintain basic weather protection. Polycarbonate damage rarely creates safety issues but may compromise insulation performance until repairs are completed.

Warranty considerations affect long-term planning. Glass typically carries 10-year warranties against manufacturing defects. Polycarbonate warranties vary from 5-10 years for UV protection and 2-5 years for impact resistance. Understanding warranty terms helps predict replacement scheduling and costs.

How Should You Balance Performance Requirements with Economic Realities?

The optimal material choice depends on your specific growing conditions, crop requirements, and financial constraints. No universal solution exists for all greenhouse applications.

Climate conditions, crop value, and operational scale determine the best material choice. High-value crops in extreme climates justify glass investment, while cost-sensitive operations in moderate climates benefit from polycarbonate. Regional factors including labor costs, shipping distances, and local regulations influence the final decision.

Regional Climate Considerations

Middle Eastern conditions favor glass for premium crop production. Extreme temperatures and intense solar radiation demand maximum durability and light transmission. High-value crops like roses, herbs, and specialty vegetables justify the additional investment. Glass maintains performance in temperatures exceeding 50°C while polycarbonate may suffer degradation.

Southeast Asian tropical conditions present different challenges. High humidity and moderate temperatures make polycarbonate attractive for cost-sensitive operations. The insulation benefits matter less in consistently warm climates. However, UV intensity remains high, requiring quality polycarbonate with proper UV protection.

European climates benefit from polycarbonate’s insulation properties. Energy costs for heating make thermal efficiency critical. The moderate UV levels extend polycarbonate service life while insulation benefits reduce operational costs significantly. Many European growers choose polycarbonate for energy-intensive crops.

Central Asian extreme conditions test both materials severely. Temperature swings from -30°C to +45°C create thermal stress challenges. Glass handles temperature extremes better but may crack from rapid temperature changes. Quality polycarbonate with proper installation techniques can perform well with appropriate structural design.

Crop-Specific Requirements

Light-sensitive crops like roses, orchids, and premium vegetables benefit from glass clarity. Maximum light transmission supports optimal photosynthesis and flower development. The investment in glass pays through higher crop quality and market prices.

Heat-sensitive crops may prefer polycarbonate’s light diffusion properties. Uniform light distribution reduces hot spots and prevents leaf burning. Crops like lettuce, herbs, and seedlings often perform better under diffused light conditions.

Energy-intensive heating crops justify polycarbonate’s insulation benefits. Tomatoes, peppers, and cucumbers grown in cooler climates benefit from reduced heating costs. The energy savings can offset the initial material cost difference within 2-3 growing seasons.

Economic Analysis Framework

Initial investment comparison must include all system costs. Glass requires heavier structures, specialized installation, and higher transportation costs. Total system cost differences often exceed material price variations by 15-25%.

Operational cost analysis should span 10-15 years. Energy savings from polycarbonate insulation can be substantial in heating-intensive operations. Glass maintenance costs remain lower but replacement risks are higher.

Financing considerations affect material choice. Higher upfront costs for glass systems may strain project budgets. Polycarbonate’s lower initial investment allows faster project implementation and cash flow improvement.

Market positioning influences material selection. Premium growers serving high-end markets often choose glass for image and performance benefits. Cost-focused operations prioritize polycarbonate’s economic advantages.

Conclusion

Material selection shapes your greenhouse’s performance, costs, and profitability for decades. Choose based on climate, crops, and economic priorities rather than following industry trends.