Winter’s freezing temperatures threaten greenhouse plants with sudden death. Without proper insulation, heating costs can skyrocket, putting your entire growing operation at risk. These 16 proven tips will save both your plants and your budget.

Effective greenhouse winter protection combines proper insulation, strategic heating, and smart design. DIY solutions work well for hobbyists, while commercial operations benefit from thermal curtains and advanced systems. The key is creating multiple heat retention barriers while maximizing natural solar gain to minimize energy consumption.

Having managed greenhouses in some of the coldest regions, I’ve learned that winter protection isn’t just about cranking up heaters. It’s about creating smart systems that trap heat efficiently. Let me share the approaches that have saved countless plants (and dollars) over my decades in greenhouse management.

DIY Insulation for Small Greenhouses: Economical and Practical Methods?

Home greenhouses lose heat rapidly through thin walls and gaps, killing tender plants overnight. Expensive heating solutions drain your wallet, but simple DIY insulation methods can save your plants and budget with materials you might already have.

DIY greenhouse insulation uses bubble wrap, recycled materials, thermal mass, and draft sealing to create effective heat barriers. These low-cost solutions can maintain temperatures 5-10°F higher than outside, often making the difference between plant survival and frost damage.

My first experience with DIY greenhouse insulation came after losing an entire crop of seedlings during an unexpected cold snap. The financial loss was significant, but the wasted time hurt even more. After researching extensively, I discovered that effective insulation doesn’t need to be expensive or complicated.

Bubble Wrap: The Home Grower’s Secret Weapon

Horticultural bubble wrap remains the champion of DIY solutions. Unlike regular packaging bubble wrap, the greenhouse variety has larger bubbles and UV stabilization. Simply attach it to the interior of your greenhouse frame using clips, leaving a small air gap between the covering and the bubble wrap. This creates a double-glazing effect, reducing heat loss by up to 50%.

For those on tight budgets, regular bubble wrap works too, though it degrades faster. I’ve used it successfully on my starter greenhouse, replacing it annually. Apply it with the bubbles facing the glass to maximize the insulating air pockets. The light diffusion actually benefits many plants during winter’s limited daylight.

Recycled Materials That Outperform Commercial Products

Old carpets, blankets, and even cardboard can become powerful insulators when used strategically. Around the base of your greenhouse, external banks of leaves or straw protected by cardboard create an excellent thermal barrier. Inside, water-filled containers painted black absorb daytime heat and release it slowly overnight – I’ve measured temperature differences of 3-4°F using this method alone.

Strategic Draft Sealing Points

Most small greenhouses leak air extensively, with each gap accelerating heat loss. I systematically check all entry points, panel overlaps, and foundation contact areas using the incense test – watching where smoke gets drawn shows exact leak locations. Weatherstrip tape, silicone caulk, and expanding foam (applied carefully) have sealed countless leaks in my structures. Pay special attention to door frames, which often warp with age and moisture.

Low-Cost Heat Retention Tricks

Beyond basic insulation, several DIY tricks significantly improve heat retention. Placing reflective foil behind radiators or heating elements directs more heat inward rather than losing it through walls. Creating thermal breaks with foam insulation strips between metal framework and panels prevents conductive heat loss through the greenhouse structure itself.

I’ve also found that subdividing larger spaces with plastic sheeting creates manageable heating zones, allowing you to maintain higher temperatures only where necessary. This approach has reduced my heating costs by 25-30% in medium-sized structures.

Temporary Night-Time Solutions

For small greenhouses, temporary coverings provide excellent nighttime protection. Frost blankets, horticultural fleece, and even old bed sheets draped directly over plants create micro-environments several degrees warmer than the surrounding air. I keep a collection of these materials ready for unexpected cold snaps.

For even better results, create support hoops to hold coverings above plants, creating an insulating air layer. This "double dome" effect significantly increases protection. I’ve successfully overwintered tender perennials in unheated greenhouses using only this method in zones much colder than the plants’ normal hardiness ranges.

Professional Insulation for Commercial Greenhouses: Thermal Curtain Systems and Multifunctional Covers?

Commercial greenhouse operations face devastating crop losses and budget-breaking heating costs during winter. Standard insulation often fails at scale, but professional thermal systems can reduce energy costs by up to 60% while maintaining optimal growing environments.

Professional greenhouse insulation relies on automated thermal curtain systems, multi-layer covering materials, and computerized climate control. These technologies create dynamic insulation that responds to changing conditions, maximizing daytime heat gain while minimizing nighttime losses.

When I consulted for a 3-acre tomato operation in a cold northern climate, their heating bills consumed nearly 40% of their winter operational costs. The existing structure had basic insulation but lacked the sophisticated systems needed for true efficiency. Implementing professional insulation solutions transformed their operation’s profitability.

Thermal Curtain Systems: The Commercial Standard

Modern thermal curtain systems represent the most significant advancement in greenhouse insulation technology. These curtains, typically made from aluminized polyester fabric, deploy automatically at sunset, creating an insulating layer that reduces heat loss through the greenhouse roof and walls. The best systems save 35-60% on heating costs.

The key factors in thermal curtain efficiency include proper installation, material selection, and automation. Edge sealing – where curtains meet greenhouse structures – prevents warm air from escaping around the curtains. Without proper sealing, efficiency drops dramatically. During installation for a client in Europe, we discovered that improving edge seals alone increased energy savings by an additional 12%.

Multi-layer curtains offer even greater benefits. Systems combining a highly reflective aluminum layer with multiple fabric layers create superior insulation while still allowing moisture management. The initial investment typically returns within 1-3 growing seasons through energy savings.

Advanced Covering Materials for Year-Round Performance

Commercial greenhouse covering materials have evolved significantly beyond basic polyethylene. Today’s multi-wall polycarbonate panels and specialized ETFE films offer superior insulation while maintaining excellent light transmission. These materials create permanent insulation rather than seasonal solutions.

Double and triple-wall polycarbonate panels create dead air spaces that dramatically reduce heat transfer. While the initial investment exceeds that of film coverings, the 15+ year lifespan and 40-60% energy savings make them economically advantageous for permanent structures. In a recent installation in Central Asia, we measured inside temperatures remaining 15-20°F above outside temperatures with minimal heating input.

Climate Control Integration: Making Insulation Dynamic

The most sophisticated commercial systems integrate insulation with comprehensive climate control. Sensors monitoring temperature, humidity, light levels, and energy consumption allow automated adjustments to insulation deployment. These systems maximize natural solar gain during daylight hours while providing optimal insulation during nights and cloudy periods.

One commercial client implemented a system that automatically adjusts thermal curtain positioning based on real-time conditions, creating partial deployments during partly cloudy days and responding to microclimates within different greenhouse zones. This dynamic approach increased growing space utilization by 8% while further reducing energy costs.

Perimeter Insulation Strategies

While roof heat loss receives the most attention, significant energy escapes through greenhouse perimeters. Professional operations now implement foundation insulation extending 24-36 inches below ground level around the entire structure. This approach blocks the thermosiphon effect that pulls heat from the greenhouse into surrounding soil.

Above ground, commercial facilities increasingly use double-wall construction with foam insulation for the first 3-4 feet of wall height. This approach maintains light levels where plants need it most while insulating the lower portions where heat loss is greatest but light transmission less critical.

Strategic Glazing Selection

Not all greenhouse covering materials perform equally in winter conditions. Professional operations now select different glazing materials for different sections of the greenhouse based on functional needs. Northern exposures receive highly insulated, less transparent materials, while southern exposures use materials optimized for light transmission with reasonable insulation values.

This targeted approach significantly outperforms using a single material throughout. For one client in Northern Europe, we implemented a system with three different covering materials based on orientation and function, resulting in 22% energy savings compared to their previous uniform covering approach.

Passive Solar Greenhouses: Energy-Saving and Eco-Friendly Heating Choices?

Traditional greenhouses demand constant energy input, draining resources and increasing carbon footprints. Passive solar designs can cut heating requirements by up to 80%, but most growers don’t understand these principles. Smart design choices create natural warming without technological complexity.

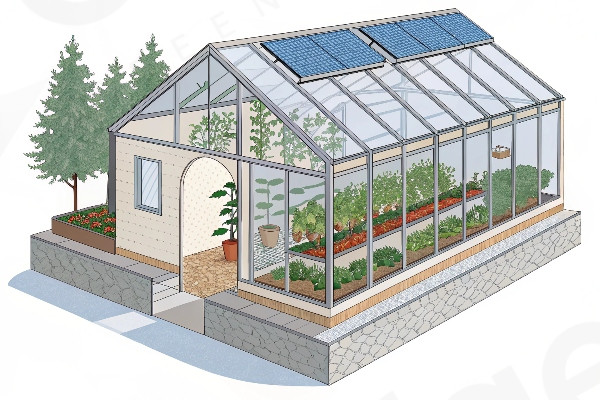

Passive solar greenhouses use strategic orientation, thermal mass, insulated north walls, and proper glazing angles to capture and store solar energy. These designs work with natural principles to maintain growing temperatures with minimal supplemental heating, even in cold climates.

My journey into passive solar greenhouse design began after calculating the environmental impact of my first commercial greenhouse operation. The fossil fuel consumption troubled me deeply, so I researched alternatives. What I discovered fundamentally changed my approach to greenhouse design and has influenced dozens of projects I’ve consulted on since.

Orientation and Glazing: The Foundation of Passive Solar

The most critical aspect of passive solar design is proper orientation. Unlike conventional greenhouses with equal glazing on all sides, passive solar structures maximize southern exposure (northern exposure in the southern hemisphere) while minimizing other glazed areas. This strategic design captures winter sunlight when the sun angle is lower while reducing nighttime heat loss.

The optimal glazing angle depends on your latitude. As a rule of thumb, perpendicular glazing to the winter sun’s angle maximizes energy capture when it’s most needed. In my designs across various climates, I’ve found that a glazing angle equal to your latitude plus 20 degrees works exceptionally well for winter performance.

The north wall (south wall in the southern hemisphere) should be heavily insulated rather than glazed. In a side-by-side comparison at a research facility, identical structures showed a 30% difference in overnight temperature retention when one replaced north glazing with insulated walls.

Thermal Mass: Nature’s Battery for Heat Storage

Effective thermal mass stores daytime solar energy and releases it slowly overnight. Water remains the most efficient commonly available thermal mass, storing approximately five times more heat energy than concrete or stone for the same volume.

My most successful implementations use water-filled containers strategically placed to receive direct sunlight. Black or dark-colored containers absorb more energy. For a small greenhouse, 3-5 gallons of water per square foot of floor area provides good temperature moderation. In commercial settings, we’ve implemented water walls consisting of stacked water-filled tubes that double as growing surfaces for vertical cultivation.

Masonry and earthen materials also function well. A technique borrowed from ancient designs incorporates a masonry wall along the north side, painted black to absorb sunlight. In one Mediterranean installation, this approach alone maintained temperatures above freezing even when outside temperatures dropped to 20°F.

Ground Heat Storage Systems

The earth beneath and around your greenhouse provides tremendous thermal stability. By tapping into this resource, passive designs1 achieve remarkable temperature regulation. French drain principles applied to greenhouse heating create underground air channels that exchange heat with the soil’s thermal mass.

In my experimental greenhouse, 8-inch drainage pipes laid in trenches 3 feet below ground level, then backfilled with gravel, create a heat exchange network. A small fan moves greenhouse air through this network during the day when temperatures rise above optimal, storing excess heat underground. At night, the same system recirculates air, retrieving stored heat. This approach moderates both winter cold and summer heat.

Bermed Designs and Earth Integration

Taking earth coupling further, partially bermed greenhouse designs use soil’s insulating properties to protect from winter winds and temperature fluctuations. By excavating into a south-facing slope and using the excavated material to berm the north, east, and west sides, these structures achieve remarkable thermal stability.

In one mountain project, we created a three-quarter bermed design that maintained growing temperatures through winter with minimal supplemental heating, despite outside temperatures regularly dropping below -10°F. The earth’s constant deep temperature (typically 50-55°F in most regions) provides a natural moderating influence.

Passive Ventilation Design

Effective winter performance requires thoughtful ventilation design. Traditional roof vents release the hottest air first – exactly what you want to retain in winter. Passive solar designs instead incorporate low intake vents and high exhaust vents with adjustable controls, allowing precise management of air exchange without sacrificing accumulated heat.

The most sophisticated passive designs1 incorporate thermal chimneys that create natural convection currents, automatically ventilating when temperatures rise too high while retaining heat when needed. These systems function without electricity, making them extremely reliable and truly passive.

FAQ: What’s the Cheapest Way to Heat a Greenhouse in Winter?

Rising energy prices make winter greenhouse heating increasingly expensive, forcing many growers to abandon winter production. Without affordable heating solutions, greenhouse potential remains untapped. Fortunately, combining several low-cost methods can maintain viable temperatures without breaking your budget.

The most economical greenhouse heating combines passive solar design, strategic insulation, microclimate creation, and targeted heating zones. Rather than heating the entire airspace, focus on root zones and create plant microclimates while maximizing insulation to prevent heat escape.

When I started my first commercial greenhouse, heating costs threatened to make winter production financially impossible. Through extensive experimentation and some costly mistakes, I discovered that the cheapest heating isn’t about finding the lowest-cost heat source—it’s about needing less heat overall and applying it more strategically.

Minimum Viable Temperatures: Knowing Your Plants’ Limits

Many growers waste energy maintaining unnecessarily high temperatures. Understanding plant-specific minimum temperature thresholds allows significant energy savings. Most cool-season vegetables (kale, spinach, lettuce) remain productive at lower temperatures than commonly believed—often as low as 40°F during night hours.

I’ve developed growing schedules that embrace these temperature minimums, allowing greenhouse temperatures to drop during nighttime hours while maintaining critical thresholds. For mixed crop greenhouses, organizing plants by temperature needs and creating temperature zones maximizes efficiency.

Soil Cable Heating vs. Air Heating

Heating soil directly rather than greenhouse air represents one of the most significant efficiency improvements available to growers. Plants primarily need warm root zones to maintain metabolic functions during cold periods. Soil heating cables use 30-70% less energy than air heating systems while providing better growing conditions.

In my commercial operations, soil cable systems maintain root zones at optimal temperatures while allowing air temperatures to fluctuate within a wider acceptable range. Young seedlings particularly benefit from bottom heat, developing stronger root systems while requiring less overall greenhouse heating.

Alternative Heating Sources

Beyond conventional heaters, several alternatives offer economical heating:

Compost heating systems harness the natural decomposition process to generate heat. Properly constructed hot compost beds can maintain temperatures of 120-140°F for weeks. Piping water through these beds creates hydronic heating systems that distribute this free heat throughout the greenhouse.

My experimental greenhouse utilizes a 4’x8′ active compost system that heats 100 square feet of growing space. The key is maintaining the proper carbon-to-nitrogen ratio and moisture levels in the compost. When properly managed, these systems provide reliable heat while converting waste materials into valuable growing medium.

Rocket mass heaters represent another efficient alternative, burning small-diameter wood at extremely high temperatures with remarkable efficiency. The heated thermal mass (typically cob, masonry, or water) releases heat slowly over many hours. A properly constructed rocket mass heater can heat a small to medium greenhouse for 12-24 hours on a single small load of wood.

Microclimates Within Greenhouses

Creating protected zones within your greenhouse dramatically reduces overall heating requirements. Row covers, cold frames, and hot beds establish microclimates that remain several degrees warmer than the main greenhouse space. This "greenhouse within a greenhouse" approach allows you to maintain critical growing areas at higher temperatures while letting the main structure temperature fluctuate more widely.

In commercial applications, I’ve implemented automated roll-up row covers that deploy at sunset, creating protected microclimates overnight. These simple systems reduce heating costs by allowing main greenhouse temperatures to drop 10-15°F lower than would otherwise be possible while keeping plants protected.

Humidity Management as Heat Retention

Many growers overlook humidity’s role in greenhouse heat retention. Proper humidity levels (50-70%) allow plants to better withstand lower temperatures while reducing heating demand. Excessively dry winter greenhouses require more heating energy, as dry air holds less heat energy.

Strategic watering in late afternoon raises humidity levels just before the challenging overnight period. However, this must be balanced with proper air circulation to prevent disease development. I’ve found that maintaining slightly higher humidity with good air movement reduces heating requirements by approximately 8-15% compared to dry, stagnant conditions.

Solar-Powered Heating Solutions

Recent advances in solar technology make solar-assisted heating increasingly viable. Small solar air heaters mounted on south-facing walls provide daytime heating boost without operational costs. These systems work particularly well when coupled with thermal mass that stores the collected heat.

For more sophisticated operations, solar hot water systems provide exceptional efficiency. Even in northern climates, evacuated tube solar collectors generate significant heat during winter daylight hours. This heat, stored in insulated water tanks, can be circulated through the greenhouse overnight via radiators or in-soil tubing.

Conclusion

Effective winter greenhouse warming combines multiple strategies: insulation to retain heat, smart design to capture solar energy, and targeted heating that focuses on plant needs. By implementing these 16 techniques, you’ll protect your plants through the coldest months while keeping costs manageable. Your greenhouse can remain productive year-round with these proven approaches.