Picture this: your crops are wilting, energy bills are skyrocketing, and you’re losing money every day your greenhouse overheats. I’ve seen this happen to countless growers in tropical regions.

After 29 years of building greenhouses in hot climates, I can tell you that proper design, smart materials, and efficient cooling systems can reduce your greenhouse temperature by 15-20°C while cutting energy costs by up to 40%. This comprehensive guide is packed with actionable tips for designing and optimizing hot climate greenhouses, ensuring your agricultural investment thrives.

At CFGET, we’ve installed over 500 greenhouses across Southeast Asia, Central Asia, and tropical regions worldwide. Each project taught us something new about fighting extreme heat. Today, I want to share everything we’ve learned about building greenhouses that actually work in hot climates.

Don’t Miss:——Commercial Hydroponic Greenhouse Systems: How Do Design, Construction, and ROI Interconnect?

You might like:——What is a Smart Greenhouse? The Ultimate Guide to Automated Growing

What Makes Hot Climate Greenhouse Design So Critical?

Your greenhouse might look perfect, but if it can’t handle 40°C+ temperatures, you’re setting yourself up for failure. Most growers underestimate how quickly heat can destroy their investment.

Hot climate greenhouses need 6-meter shoulder heights, massive ventilation systems, and specialized cooling designs. Without these features, your crops will suffer heat stress, and your energy bills will triple. Understanding these needs is vital for anyone looking to succeed in agriculture in hot climates.

The Science Behind Hot Climate Greenhouse Success

When I first started designing greenhouses for tropical regions, I made every mistake in the book. Standard greenhouse designs simply don’t work when outside temperatures hit 45°C. The physics are completely different.

Heat rises, but in a short greenhouse, it has nowhere to go. This creates a heat dome effect that can push internal temperatures to 60°C or higher. That’s why we always design our hot climate greenhouses with 6-meter shoulder heights minimum. The extra height creates natural thermal stratification, allowing for better temperature management.

The roof peak should reach 8-10 meters. This gives hot air a place to collect while keeping the growing zone cooler. We also angle the roof at 25-30 degrees to maximize hot air escape through ridge vents.

| Design Element | Standard Greenhouse | Hot Climate Greenhouse |

|---|---|---|

| Shoulder Height | 3-4 meters | 6+ meters |

| Roof Peak | 5-6 meters | 8-10 meters |

| Roof Angle | 15-20 degrees | 25-30 degrees |

| Ventilation Area | 15-20% of floor | 25-35% of floor |

Ventilation area is crucial. We calculate at least 25% of the floor space should be ventilation openings. In extreme climates, we go up to 35%. This seems excessive, but it’s necessary for proper air exchange.

How Do You Choose the Right Covering Materials for Extreme Heat?

Cheap plastic sheeting might save money upfront, but it will cost you thousands in cooling bills. The wrong covering material can turn your greenhouse into an oven.

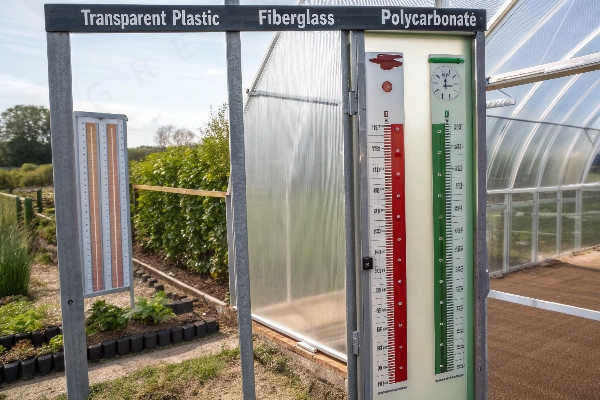

Polycarbonate panels with UV protection and light diffusion properties reduce heat buildup by 30% compared to standard plastic films, while maintaining optimal light transmission for plant growth. Selecting the right materials is crucial for long-term success in hot climate greenhouses.

Material Selection Strategy for Hot Climates

After testing dozens of covering materials in scorching conditions, I’ve learned that not all greenhouse coverings are created equal. The material you choose can make the difference between success and failure.

Standard polyethylene film is the worst choice for hot climates. It traps heat, degrades quickly under UV exposure, and offers no insulation benefits. I’ve seen greenhouses covered with cheap PE film reach internal temperatures of 70°C on 40°C days.

Twin-wall polycarbonate is our go-to choice for most hot climate projects. The air gap between walls provides insulation that works both ways. It keeps heat out during the day and prevents rapid temperature drops at night. The light diffusion properties also prevent hot spots that can burn plants.

For ultra-premium projects, we use triple-wall polycarbonate with special heat-reflective coatings. These panels can reflect up to 40% of infrared radiation while maintaining 85% light transmission. The initial cost is high, but the energy savings pay for themselves within 2-3 years.

Glass is surprisingly effective in hot climates when properly treated. Low-E coatings and ceramic frits can create selective light transmission. The thermal mass of glass also helps moderate temperature swings. However, glass requires stronger structural support and costs more to install.

| Material | Heat Reduction | Light Transmission | Lifespan | Cost Factor |

|---|---|---|---|---|

| Standard PE Film | 0% | 90% | 2-3 years | 1x |

| Twin-wall PC | 25% | 85% | 10-15 years | 3x |

| Triple-wall PC | 35% | 82% | 15-20 years | 5x |

| Low-E Glass | 30% | 88% | 25+ years | 6x |

Why Does Greenhouse Structure Matter More Than You Think?

Many growers focus on cooling systems but ignore the structure itself. A poorly designed frame can negate even the best cooling equipment. Structure is your first line of defense against heat.

Proper greenhouse orientation, frame materials, and foundation design can reduce cooling loads by 25-40% before you even install mechanical systems. Aluminum frames conduct 3x less heat than steel.

Structural Optimization for Maximum Cooling Efficiency

The orientation of your greenhouse affects cooling requirements more than most people realize. After analyzing hundreds of installations, we’ve found that east-west orientation typically performs better in hot climates than north-south.

East-west orientation means the long sides face north and south. This reduces the surface area exposed to the intense midday sun. The short ends face east and west, minimizing heat gain during the hottest part of the day. This simple change can reduce cooling loads by 15-20%.

Frame material choice impacts heat transfer significantly. Steel frames conduct heat rapidly, creating thermal bridges that pump heat into the greenhouse. Aluminum frames conduct less heat and reflect more solar radiation. For ultimate performance, we use thermally broken aluminum profiles1 that virtually eliminate heat conduction.

Foundation design often gets overlooked, but it’s critical for hot climate performance. Concrete foundations absorb heat during the day and radiate it into the greenhouse at night. We now use insulated foundations with rigid foam barriers that prevent ground heat transfer.

Structural spacing affects both strength and cooling. Wider spacing between supports allows better airflow but requires stronger materials. We typically use 4-meter spacing for the structural frame and 2-meter spacing for secondary supports. This provides the strength needed for wind loads while maximizing ventilation efficiency.

The roof structure deserves special attention. Ridge vents should run the full length of the greenhouse with no obstructions. We design continuous ridge vents that are 60-80cm wide. Louvre vents at the sidewalls should be positioned low for air intake and high for exhaust, creating a natural chimney effect.

What Are the Most Effective Energy-Saving Cooling Techniques?

Active cooling systems work, but they’re expensive to run. Smart growers combine passive cooling2 with targeted active systems to minimize energy costs while maintaining perfect climate control.

Shade net houses integrated with evaporative cooling can reduce temperatures by 12-15°C using 70% less energy than traditional air conditioning systems. The key is layered cooling strategies. Implementing these techniques can lead to better crop health and lower operating costs, especially in hot climates.

Advanced Cooling Strategies That Actually Work

Passive cooling should always be your first priority. Natural ventilation can handle surprising heat loads when properly designed. We size intake vents at ground level to be 30% larger than exhaust vents at the roof. This creates positive pressure that drives hot air out while pulling cool air in.

Shade systems are essential but often poorly implemented. External shade cloths work better than internal ones because they prevent heat from entering the greenhouse in the first place. We use retractable shade systems that can automatically adjust based on light levels and temperature.

Evaporative cooling is extremely effective in dry climates but less useful in humid regions. Pad and fan systems can drop temperatures by 10-15°C in arid areas. However, in humid tropical climates, evaporative cooling3 may actually increase heat stress by raising humidity levels.

For high-value crops, we design semi-closed systems with independent cooling zones. These systems create a sealed growing environment within the larger greenhouse structure. Refrigerated air is distributed through insulated ducts to maintain precise temperature control.

The most innovative approach combines multiple cooling strategies in a smart control system. Sensors monitor temperature, humidity, and light levels to automatically adjust ventilation, shading, and active cooling. This prevents energy waste while maintaining optimal growing conditions.

Misting systems provide localized cooling around plants without cooling the entire greenhouse volume. High-pressure misting can reduce leaf temperature by 8-10°C through evaporation. The key is using pure water and proper nozzle spacing to prevent oversaturation.

| Cooling Method | Temperature Reduction | Energy Cost | Best Climate |

|---|---|---|---|

| Natural Ventilation | 5-8°C | Minimal | All climates |

| External Shading | 6-10°C | Minimal | All climates |

| Evaporative Cooling | 10-15°C | Low | Dry climates |

| Misting Systems | 8-12°C | Medium | Moderate humidity |

| Semi-closed Systems | 15-20°C | High | Extreme climates |

Conclusion

Building successful hot climate greenhouses requires integrated design thinking, proper materials, and smart cooling strategies. With 28 years of experience, I can guarantee these principles will transform your growing operation for the better. Whether you’re a large agricultural producer or a small grower, implementing these strategies will help you thrive in hot climates. By focusing on these key elements, you can ensure your greenhouse remains productive and cost-effective, even in the harshest conditions.

-

Explore how thermally broken aluminum profiles can enhance energy efficiency and reduce heat transfer in greenhouses. ↩

-

Learn about effective passive cooling strategies that can significantly reduce energy costs and improve crop health in greenhouses. ↩

-

Discover the advantages of evaporative cooling systems in maintaining optimal temperatures in dry climates for better crop yields. ↩