Choosing the wrong greenhouse covering material can cost you thousands in repairs and lost crops. Many growers struggle with this decision every day.

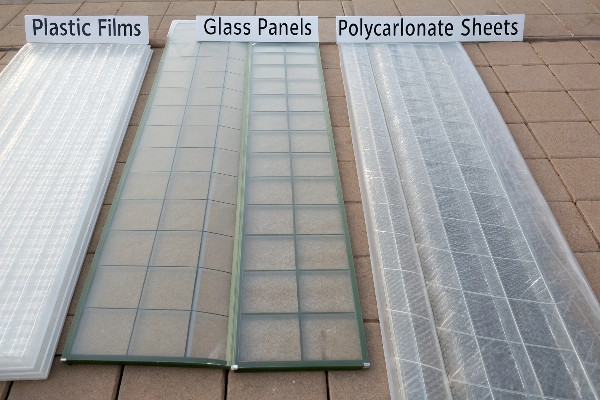

The key differences between polycarbonate and glass include light transmission, weight, insulation, cost, and durability. Polycarbonate offers better insulation and impact resistance, while glass provides superior light clarity and longevity. Your choice depends on climate, crops, and budget.

After 29 years in the greenhouse industry, I’ve seen countless growers make costly mistakes with covering materials. The decision between polycarbonate and glass isn’t just about upfront costs. It affects your entire operation for decades.

Don’t Miss:——Commercial Greenhouse Materials Showdown: Polycarbonate vs Glass – Which Covering Will Maximize Your 2025 ROI?

You might like:——What is a Smart Greenhouse? The Ultimate Guide to Automated Growing

Light Quality: How Anti-Drip Design Affects Polycarbonate’s Actual Light Transmission?

Poor light transmission kills plant growth. Many growers don’t realize how coating treatments change everything.

Anti-drip coatings on polycarbonate can reduce light transmission by 2-5%, but they prevent water droplets that would otherwise block 10-15% more light. The net result is actually improved light quality for plant growth.

I remember visiting a tomato grower in Thailand who complained about poor yields. His polycarbonate panels had no anti-drip coating. Water droplets covered 30% of the surface during humid mornings. The plants received inconsistent light all day.

Light transmission numbers on spec sheets don’t tell the whole story. Standard polycarbonate transmits 88-92% of light. Glass transmits 90-95%. But these numbers ignore real-world conditions.

Anti-drip coatings work through surface tension modification. They spread water into thin films instead of droplets. This maintains consistent light transmission even in high humidity. The coating adds a slight tint that reduces transmission by 2-5%. However, it prevents the 10-15% loss from water droplets.

| Material Type | Lab Light Transmission | Real-World Transmission | Humidity Impact |

|---|---|---|---|

| Standard Glass | 92-95% | 85-90% | High droplet formation |

| Polycarbonate (no coating) | 88-92% | 70-80% | Severe droplet issues |

| Polycarbonate (anti-drip) | 85-90% | 85-88% | Minimal droplet formation |

The coating also affects light diffusion. Polycarbonate naturally diffuses light better than glass. This reduces hot spots and shadows inside the greenhouse. Plants receive more even light distribution throughout the day.

UV protection is another factor. Quality polycarbonate blocks 99% of UV rays. This protects both plants and the material itself. Glass blocks some UV naturally but not as effectively as treated polycarbonate.

Structure and Installation: Requirements of Lightweight Polycarbonate vs. Heavy Glass on Framework and Foundation?

Heavy materials demand expensive foundations. Most growers underestimate these hidden costs completely.

Glass weighs 10-15 times more than polycarbonate, requiring reinforced frameworks and deeper foundations. This increases construction costs by 20-30% and extends installation time by 40-60% compared to polycarbonate systems.

Last year, I worked with a client in Kazakhstan who wanted to switch from polycarbonate to glass. The existing foundation couldn’t support the weight. We had to redesign the entire structure. The foundation work alone cost $50,000 extra.

Weight affects every aspect of construction. Standard 4mm polycarbonate weighs 0.8 kg per square meter. Single-pane glass weighs 12-15 kg per square meter. Double-pane glass reaches 20-25 kg per square meter.

Foundation requirements change dramatically with weight. Polycarbonate greenhouses need foundations 30-40cm deep. Glass greenhouses require 60-80cm depth with reinforced concrete. The concrete volume increases by 150-200%.

Framework design must handle different loads. Polycarbonate allows lighter aluminum frames with 2-3 meter spacing. Glass requires heavier steel frames with 1.5-2 meter spacing. The frame weight alone doubles the total load.

Installation complexity varies significantly. Polycarbonate panels install with simple clips and seals. Two workers can handle most panels easily. Glass requires specialized equipment and trained glaziers. Safety requirements increase costs and time.

| Factor | Polycarbonate | Single Glass | Double Glass |

|---|---|---|---|

| Weight (kg/m²) | 0.8-1.2 | 12-15 | 20-25 |

| Foundation Depth | 30-40cm | 60-70cm | 70-80cm |

| Frame Spacing | 2-3m | 1.5-2m | 1.5-2m |

| Installation Time | 1-2 days | 3-5 days | 5-7 days |

Wind load calculations become critical with glass. The heavy panels create more stress during storms. Frame connections need stronger bolts and brackets. Insurance costs often increase for glass structures.

Thermal expansion creates different challenges. Glass expands less than polycarbonate but puts more stress on frames. Polycarbonate flexes with temperature changes. Glass can crack if the frame doesn’t accommodate movement properly.

Lifespan and Maintenance: Comparing Material Durability, UV Resistance, and Repair Costs?

Maintenance costs destroy budgets over time. Many growers focus only on initial prices and ignore long-term expenses.

Quality polycarbonate lasts 10-15 years with proper UV protection, while glass can last 25-30 years. However, polycarbonate maintenance costs 60% less annually due to easier repairs and cleaning requirements.

I’ve maintained greenhouses for nearly three decades. The biggest surprise for new growers is how maintenance costs add up. A client in Morocco spent $15,000 yearly maintaining glass panels. His neighbor with polycarbonate spent $6,000 for the same area.

UV resistance determines lifespan more than any other factor. Quality polycarbonate includes UV-blocking additives throughout the material. Cheap polycarbonate without UV protection fails within 2-3 years. The surface becomes cloudy and brittle.

Glass doesn’t degrade from UV exposure. However, it faces other challenges. Thermal stress creates micro-cracks over time. Hail damage is expensive to repair. Replacement costs are 3-4 times higher than polycarbonate.

Cleaning requirements differ significantly. Polycarbonate attracts more dust due to static charge. However, it cleans easily with soap and water. Glass stays cleaner longer but requires careful handling during cleaning. Scratches are permanent on glass.

| Maintenance Factor | Polycarbonate | Glass |

|---|---|---|

| Expected Lifespan | 10-15 years | 25-30 years |

| Annual Cleaning Cost | $2-3/m² | $4-6/m² |

| Repair Frequency | Low impact damage | High thermal stress |

| Replacement Cost | $15-25/m² | $45-65/m² |

Hail damage reveals the biggest difference. Polycarbonate dents but rarely breaks completely. Glass shatters and requires immediate replacement. I’ve seen entire glass greenhouses destroyed by single hailstorms.

Thermal cycling affects both materials differently. Polycarbonate becomes more flexible over time. Glass becomes more brittle. Expansion joints require regular maintenance in glass structures. Polycarbonate seals need replacement every 5-7 years.

Warranty terms reflect these differences. Quality polycarbonate comes with 10-year UV warranties. Glass typically offers 5-year warranties against manufacturing defects. Labor warranties are shorter for glass due to installation complexity.

For Specific Crops & Climates: How to Choose the Right Greenhouse Material for Your Farm?

Wrong material choices kill profits before you even plant. Climate and crop requirements must match your covering material perfectly.

High-value crops in extreme climates benefit from glass durability, while cost-sensitive operations in moderate climates perform better with polycarbonate. Climate factors like hail, wind, and humidity levels determine the optimal choice more than crop type alone.

The Middle East taught me this lesson clearly. I worked with rose growers in Dubai who insisted on polycarbonate for cost savings. The extreme heat and sandstorms destroyed the panels within three years. They switched to glass and haven’t replaced a panel in eight years.

Climate conditions override crop preferences in most cases. Hail-prone areas need impact-resistant materials. Coastal regions require corrosion-resistant frames. Desert climates demand UV-stable materials.

Temperature extremes affect material choice significantly. Polycarbonate insulates better in cold climates. The double-wall structure provides R-value of 1.6-2.0. Single glass offers only R-value of 0.9. However, extreme heat above 50°C can warp polycarbonate.

Humidity levels determine condensation management needs. High humidity areas benefit from anti-drip coatings. Glass condensation drips directly onto plants. Polycarbonate with proper coatings spreads moisture evenly.

| Climate Type | Recommended Material | Key Benefits | Typical Crops |

|---|---|---|---|

| Hot Arid (Middle East) | Glass | Heat resistance, durability | Roses, herbs, leafy greens |

| Humid Tropical (Southeast Asia) | Film or Polycarbonate | Cost effective, easy replacement | Vegetables, flowers |

| Temperate (Europe/North America) | Polycarbonate or Glass | Insulation, versatility | Tomatoes, peppers, cucumbers |

| Cold (Northern regions) | Double-wall Polycarbonate | Superior insulation | Winter crops, seedlings |

Crop value determines economic viability. High-value crops like roses, orchids, and medicinal plants justify glass costs. The superior light transmission and longevity provide better returns. Commodity crops like lettuce and herbs work well with polycarbonate.

Wind resistance becomes critical in exposed locations. Glass handles steady winds better due to rigidity. Polycarbonate flexes with gusts but can fatigue over time. Frame design must accommodate material properties.

Maintenance access affects material choice. Remote locations favor polycarbonate due to easier repairs. Urban areas with skilled glaziers can maintain glass systems effectively. Parts availability varies by region.

For commercial greenhouse applications, the choice between polycarbonate and glass depends on local climate conditions and the crop’s growing environment. In the Middle East, most customers grow high-end crops and opt for glass or PC panels. In the hot regions of Southeast Asia, film greenhouses are more suitable due to their lower construction costs. The choice of which type of commercial greenhouse depends on the climate conditions and the growing environment for the crops within the greenhouse. There is no "better" option, only a more suitable one.

Conclusion

Choose greenhouse covering materials based on your specific climate, crops, and budget rather than following general recommendations. Both polycarbonate and glass serve different purposes effectively when matched correctly to conditions.