Your greenhouse glass choice can make or break your crop yields. Poor glass selection wastes energy and reduces plant growth by up to 40%.

Ultra-clear anti-reflective glass achieves 97% light transmittance while insulated units provide thermal resistance down to 1.6 W/m²K. The most efficient systems combine high transmission with superior insulation for optimal growing conditions.

After nearly three decades in greenhouse construction, I have witnessed the evolution from basic single-pane glass to sophisticated multi-layer systems. The question of efficiency involves more than just numbers on specification sheets. Real efficiency means creating the perfect balance between light availability and energy conservation that maximizes both plant health and operational profitability.

How High is the Light Transmittance of Ultra-Clear Anti-Reflective Glass?

Standard glass blocks precious light that your plants desperately need for photosynthesis. Every percentage point of lost transmission directly impacts your harvest quality and quantity.

Ultra-clear anti-reflective glass achieves 96-97% light transmittance compared to 88-90% for standard float glass. This 7-9% improvement translates to measurable increases in plant growth rates and crop yields.

The science behind ultra-clear glass involves removing iron oxide impurities that give standard glass its greenish tint. Regular float glass contains approximately 0.1% iron oxide, which absorbs light in the red and infrared spectrums. Ultra-clear glass reduces iron content to less than 0.01%, creating crystal-clear transparency that maximizes light transmission across all wavelengths important for plant growth.

Anti-reflective coatings add another layer of efficiency by reducing surface reflection losses. Standard glass reflects approximately 4% of incident light from each surface, meaning double-glazed units lose about 16% of available light through reflection alone. Anti-reflective coatings reduce surface reflection to less than 1%, recovering most of this lost light for plant use.

I worked with a premium orchid grower in Singapore who struggled with flower quality despite using expensive growing systems. His standard glass greenhouse achieved only 85% light transmission due to multiple reflective losses and iron content absorption. We replaced his glazing with ultra-clear anti-reflective glass achieving 96% transmission. The improved light quality enhanced flower coloration and increased bloom size by an average of 15%. More importantly, the orchids developed stronger stems and better disease resistance.

The manufacturing process for ultra-clear glass requires precise control of raw materials and melting temperatures. Specialized furnaces operate at higher temperatures to ensure complete iron oxide removal. Quality control systems monitor glass composition continuously to maintain consistent optical properties. This attention to detail results in higher manufacturing costs but delivers measurable performance improvements.

Different coating technologies offer varying levels of anti-reflective performance. Single-layer coatings provide moderate reflection reduction at lower costs. Multi-layer interference coatings achieve superior performance but require more complex manufacturing processes. For greenhouse applications, single-layer coatings usually provide sufficient performance improvement to justify the additional investment.

Durability of anti-reflective coatings affects long-term performance and maintenance requirements. Hard coatings applied during glass manufacturing resist weathering and cleaning damage better than soft coatings applied after production. However, soft coatings can achieve better optical performance initially. Professional greenhouse suppliers select coating types based on local environmental conditions and maintenance capabilities.

| Glass Type | Light Transmittance | Iron Content | Surface Reflection | Net Transmission |

|---|---|---|---|---|

| Standard Float | 90% | 0.1% | 8% (both surfaces) | 83% |

| Ultra-Clear | 95% | <0.01% | 8% (both surfaces) | 87% |

| Anti-Reflective | 90% | 0.1% | 2% (both surfaces) | 88% |

| Ultra-Clear AR | 95% | <0.01% | 2% (both surfaces) | 93% |

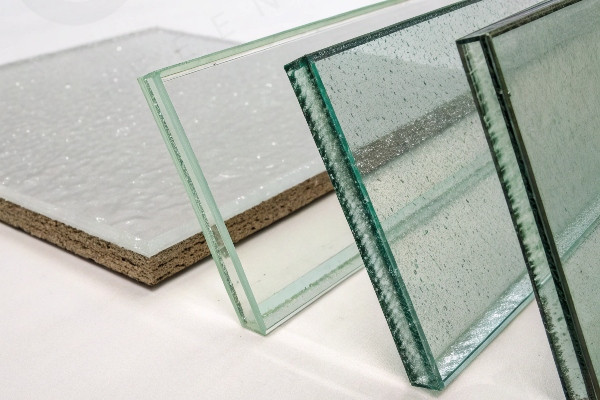

Which Type of Glass Offers the Best Insulation?

Heat loss through poor glass insulation can triple your energy costs during winter months. The right insulating glass pays for itself through reduced heating expenses.

Triple-glazed low-emissivity glass units achieve U-values as low as 1.0 W/m²K compared to 5.8 W/m²K for single glass. This represents an 83% reduction in heat transfer, dramatically lowering heating costs.

Understanding thermal performance requires examining multiple factors beyond simple glass thickness. Air gaps between glass layers create insulating barriers, but gap size affects performance significantly. Gaps smaller than 6mm allow convection currents that reduce insulation effectiveness. Gaps larger than 20mm also permit convection while requiring stronger structural support. Optimal gap sizes range from 12-16mm for most greenhouse applications.

Gas filling between glass layers improves thermal performance substantially over air-filled units. Argon gas has approximately 34% lower thermal conductivity than air, reducing heat transfer through the insulated glass unit. Krypton gas offers even better performance with 50% lower conductivity than air, but costs significantly more. For most commercial greenhouse applications, argon-filled units provide the best balance of performance and economics.

I remember working with a vegetable grower in northern Canada who faced enormous heating costs during harsh winters. His original single-glass greenhouse consumed over $50,000 annually in heating fuel. We designed a replacement system using triple-glazed argon-filled units with low-emissivity coatings. The new glazing reduced heating costs by 75%, paying for the upgrade investment within four years. The improved temperature stability also enhanced crop quality and reduced plant stress during cold periods.

Low-emissivity coatings reflect long-wave infrared radiation back into the greenhouse while allowing visible light to pass through normally. These microscopic metallic coatings are nearly invisible but significantly reduce radiative heat loss during nighttime hours when heating costs peak. Low-E coatings can reduce heat transfer by an additional 20-30% compared to uncoated insulated glass.

Spacer systems between glass layers affect both thermal performance and structural integrity. Traditional aluminum spacers create thermal bridges that reduce overall insulation effectiveness. Warm-edge spacers made from stainless steel or composite materials minimize thermal bridging while maintaining structural support. These advanced spacer systems can improve overall U-values by 10-15%.

Edge seal technology determines insulated glass unit lifespan and thermal performance retention. Primary seals prevent moisture infiltration and gas leakage while secondary seals provide structural support and weather protection. Dual-seal systems with butyl primary seals and structural silicone secondary seals offer the best combination of performance and durability for greenhouse applications.

Vacuum-insulated glass represents the ultimate in thermal performance, achieving U-values below 0.5 W/m²K. These units eliminate convection entirely by maintaining vacuum conditions between glass layers. However, manufacturing complexity and costs currently limit vacuum glass to specialized applications. For most greenhouse operations, conventional insulated glass units provide sufficient thermal performance at reasonable costs.

| Glazing System | U-Value (W/m²K) | Relative Cost | Payback Period | Best Applications |

|---|---|---|---|---|

| Single Glass | 5.8 | 1.0x | N/A | Mild climates only |

| Double Glazed | 2.8 | 2.5x | 3-5 years | Most applications |

| Low-E Double | 2.0 | 3.0x | 2-4 years | Cold climates |

| Triple Glazed | 1.6 | 4.0x | 4-6 years | Extreme cold |

| Vacuum Glass | 0.5 | 8.0x | 10+ years | Research facilities |

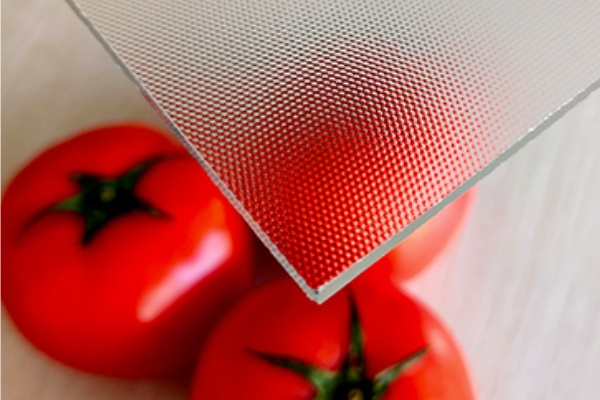

How Does Diffuse Glass Improve Light Energy Efficiency?

Direct sunlight creates hot spots and shadows that waste light energy and stress plants. Diffuse glass transforms harsh light into gentle, productive illumination.

Diffuse glass scatters incoming light to eliminate shadows and create uniform illumination throughout the greenhouse. This improved light distribution can increase photosynthesis efficiency by 10-15% compared to clear glass systems.

The physics of light diffusion involves microscopic surface textures or internal structures that scatter light rays in multiple directions. When direct sunlight hits diffuse glass, it spreads into a broad, even pattern instead of creating focused beams and sharp shadows. This scattered light penetrates deeper into plant canopies and reaches leaves that would otherwise remain shaded under clear glass systems.

Different manufacturing methods create varying levels of light diffusion. Acid-etched glass uses chemical processes to create microscopic surface roughness that scatters light. Structured glass incorporates physical patterns during the manufacturing process to achieve controlled diffusion. Internal diffusion uses microscopic particles embedded within the glass matrix to scatter light throughout its thickness. Each method offers different optical properties and durability characteristics.

I worked with a tomato producer in Mexico who struggled with uneven fruit ripening and quality variations across his greenhouse. Plants near the walls produced excellent fruit while those in the center showed poor development and delayed ripening. The problem was uneven light distribution from clear glass that created bright corridors and shaded areas. We replaced the roof glazing with structured diffuse glass providing 60% haze. The scattered light eliminated shadows and created uniform growing conditions. Tomato quality became consistent throughout the greenhouse, and overall yields increased by 12%.

Haze value selection affects both light diffusion and total transmission. Higher haze values create more uniform light distribution but may reduce overall light levels reaching plants. Lower haze values maintain higher transmission but provide less shadow reduction. Optimal haze values typically range from 30-70% depending on crop requirements and local light conditions. Leafy greens benefit from higher diffusion while fruiting crops may prefer moderate diffusion levels.

Seasonal considerations affect optimal diffusion strategies in many climates. Summer months with intense sunlight benefit from higher diffusion to reduce heat stress and prevent leaf burn. Winter months with limited natural light may require lower diffusion to maximize available photosynthetic energy. Some greenhouse operators use adjustable systems or seasonal glass replacement to optimize performance year-round.

Crop-specific diffusion requirements vary based on plant architecture and growth habits. Dense canopy crops like lettuce and herbs benefit significantly from diffuse light that penetrates deep into leaf layers. Tall crops like tomatoes and cucumbers may require different diffusion levels at various heights. Some modern greenhouses use gradient diffusion systems with varying haze values from roof to sidewalls.

The combination of diffusion and anti-reflective properties creates synergistic effects that maximize light utilization efficiency. Diffuse anti-reflective glass maintains high transmission while providing uniform distribution. This combination eliminates both reflection losses and shadow problems that reduce photosynthetic efficiency in conventional clear glass systems.

| Diffusion Type | Haze Value | Light Distribution | Maintenance | Best Crops |

|---|---|---|---|---|

| Clear Glass | 0% | Uneven | Low | Limited applications |

| Light Diffusion | 30-40% | Good | Low | Fruiting crops |

| Medium Diffusion | 50-60% | Excellent | Low | Most vegetables |

| High Diffusion | 70%+ | Maximum | Medium | Leafy greens |

How to Balance the Light Transmittance and Insulation of Greenhouse Glass?

Maximizing both light transmission and thermal insulation seems impossible, but modern glass technology offers solutions that optimize both properties simultaneously.

Advanced glazing systems achieve 85-90% light transmission while maintaining U-values below 2.0 W/m²K through selective coatings and optimized gas fills. The key is choosing systems designed specifically for horticultural applications.

The traditional trade-off between transmission and insulation no longer applies to modern greenhouse glazing systems. Early insulated glass units sacrificed significant light transmission for thermal performance. Today’s advanced systems use selective coatings and optimized designs to achieve both high transmission and excellent insulation. The secret lies in understanding which wavelengths matter most for plant growth and which contribute primarily to unwanted heat gain.

Selective low-emissivity coatings reflect long-wave infrared radiation while allowing visible and near-infrared light to pass through freely. These coatings target the specific wavelengths responsible for radiative heat loss without blocking photosynthetically active radiation. Advanced selective coatings can reduce heat transfer by 40% while maintaining over 85% visible light transmission.

I worked with a flower grower in the Netherlands who needed both maximum light for winter production and excellent insulation to control heating costs. Traditional approaches required choosing between light and thermal performance. We designed a custom glazing system using ultra-clear glass with selective low-E coatings and argon gas filling. The system achieved 87% light transmission with a U-value of 1.8 W/m²K. Winter flower production increased by 20% while heating costs dropped by 55%.

Gas selection between glass layers affects both thermal and optical performance. While argon provides excellent thermal insulation, it also slightly reduces light transmission compared to air. However, the thermal benefits usually outweigh the small optical losses. Advanced gas mixtures can optimize this balance further, though costs may limit their use to specialized applications.

Glazing system design affects the balance between transmission and insulation through multiple factors. Glass thickness influences both properties, with thicker glass providing better thermal performance but potentially reducing transmission. Spacer width affects thermal performance while influencing optical properties through internal reflections. Professional greenhouse glazing systems optimize all these factors simultaneously.

Regional climate considerations determine the optimal balance point between transmission and insulation. Cold climates with limited winter sunlight prioritize thermal performance to reduce heating costs while maintaining adequate light levels. Warm climates with abundant sunlight may prioritize transmission to maximize plant growth while providing sufficient insulation for temperature control.

Economic analysis helps determine the optimal balance for specific operations. Higher transmission glass may increase crop yields and quality, generating additional revenue. Better insulation reduces operating costs but requires higher initial investment. Professional greenhouse designers use economic modeling to identify the glazing system that maximizes long-term profitability for each application.

Maintenance requirements affect the long-term balance between transmission and insulation. Some high-performance coatings require special cleaning procedures to maintain optical properties. Insulated glass units need regular inspection to ensure seal integrity and thermal performance. Proper maintenance planning ensures that glazing systems maintain their design performance throughout their service life.

| Glazing Configuration | Light Transmission | U-Value | Relative Cost | Optimal Applications |

|---|---|---|---|---|

| Single Ultra-Clear | 95% | 5.8 W/m²K | 1.5x | Warm climates |

| Double Low-E | 82% | 2.0 W/m²K | 3.0x | Temperate zones |

| Triple Low-E | 75% | 1.6 W/m²K | 4.5x | Cold climates |

| Selective Coating | 87% | 1.8 W/m²K | 3.5x | Balanced performance |

Conclusion

The most efficient greenhouse glass balances ultra-clear transmission with advanced insulation, achieving 85%+ light levels while maintaining U-values below 2.0 W/m²K for optimal growing conditions.