Your greenhouse crops are dying from heat stress while your electricity bills skyrocket from running fans and cooling systems all day.

Sawtooth greenhouse roofs create continuous natural airflow through thermal physics, eliminating the need for powered ventilation while reducing internal temperatures by 6-10°C in tropical climates.

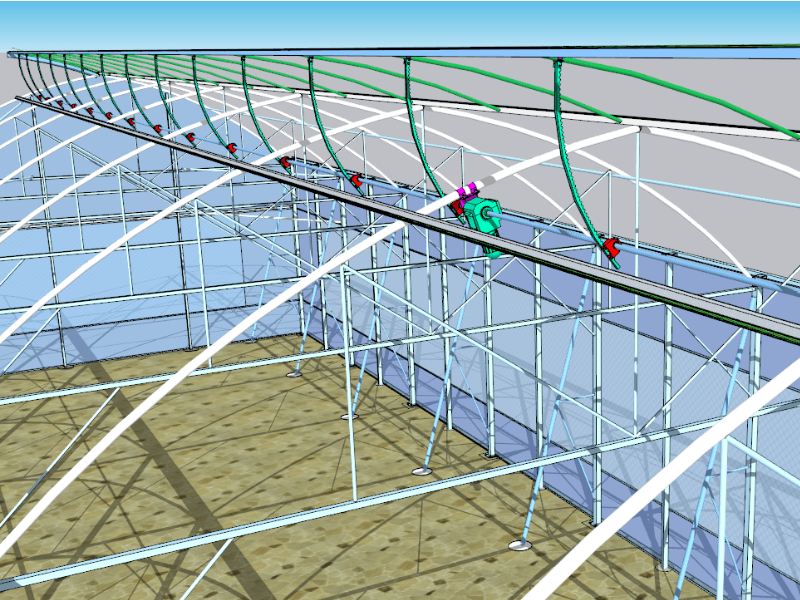

Distinctive sawtooth roof design maximizing natural airflow.

After installing sawtooth greenhouses across Southeast Asia’s most challenging climates, we’ve watched farmers transform failing operations into profitable ventures simply by harnessing natural physics for cooling. When a tomato grower in central Thailand told us his crops were cooking despite running twelve exhaust fans continuously, we knew the sawtooth design would solve his problem. Six months later, his plants thrive in naturally ventilated comfort while his electricity costs dropped to nearly zero.

The Genius of the Sawtooth Roof: How It Creates Constant, Natural Airflow?

Traditional greenhouse roofs trap hot air at the peak, creating deadly heat zones that kill crops and stress workers.

The sawtooth roof design creates multiple high and low pressure zones that force continuous air circulation through the stack effect, moving hot air out through ridge vents while drawing cool air in through side openings automatically.

Physics-based airflow creating continuous natural ventilation.

Understanding the Stack Effect in Action

The sawtooth roof works on a simple principle – hot air rises and seeks the easiest exit path. Each sawtooth peak creates a high point where heated air naturally accumulates and escapes through ridge vents. Meanwhile, the lower valleys draw in cooler outside air through strategically placed openings. This creates multiple circulation cells across the greenhouse length, ensuring no dead air zones develop.

We measure airflow rates in our sawtooth installations using anemometers placed throughout the structure. Even on calm days with minimal wind, internal air movement averages 0.8-1.2 meters per second – sufficient to prevent heat buildup and maintain plant transpiration. When external breezes occur, the sawtooth design amplifies their effect, creating internal air speeds of 2-3 meters per second without any mechanical assistance.

| Roof Design | Air Changes/Hour | Peak Temperature | Energy Cost/Month |

|---|---|---|---|

| Traditional Peaked | 2-4 | 48°C | $340 (with fans) |

| Sawtooth Natural | 8-12 | 38°C | $0 |

| Sawtooth + Fans | 15-20 | 35°C | $85 |

| Climate Controlled | 25-30 | 32°C | $680 |

The beauty lies in the self-regulating nature. As internal temperatures rise, the temperature differential between inside and outside air increases, accelerating the stack effect. This means ventilation automatically intensifies when cooling is most needed. During cooler morning and evening hours, the gentler temperature gradient provides adequate but not excessive air movement, maintaining stable growing conditions.

Optimizing Vent Placement for Maximum Effect

Vent positioning determines the entire system’s effectiveness. We place ridge vents at the peak of each sawtooth section, typically 30-40cm wide running the full greenhouse length. These high-level exhausts remove the hottest air layers. Side wall vents position at plant level, approximately 1.5 meters above ground, allowing cool air intake without creating drafts on sensitive crops.

The ratio between intake and exhaust areas affects ventilation balance. We design exhaust vents 20% larger than intake vents to ensure positive airflow direction. This prevents outside contaminants from entering while maintaining strong internal circulation. Adjustable louvers on both intake and exhaust vents allow fine-tuning based on seasonal conditions and crop requirements.

From Heat Stress to Healthy Harvests: The #1 Benefit for Tropical Growers?

Extreme heat destroys crop quality, reduces yields, and makes greenhouse farming unprofitable in tropical regions.

Sawtooth ventilation maintains optimal growing temperatures of 28-32°C even when outside temperatures exceed 40°C, enabling consistent production of heat-sensitive crops like lettuce, herbs, and premium tomatoes year-round.

Healthy crops thriving under optimal sawtooth ventilation.

Real Results from Tropical Installations

Our most dramatic success occurred in Malaysia’s Cameron Highlands, where a lettuce farmer struggled with crop failures during hot seasons. Traditional greenhouse designs trapped heat, causing lettuce to bolt prematurely and develop bitter flavors that made them unmarketable. After converting to sawtooth design, the same varieties now produce crisp, sweet lettuce throughout the year.

The temperature stability proves crucial for consistent quality. In conventional greenhouses, we recorded temperature swings of 15-20°C between morning and afternoon. The sawtooth design reduces these fluctuations to just 6-8°C, providing the stable environment that high-value crops require. This consistency allows precise irrigation and fertilization scheduling, further improving crop quality and yields.

Heat stress symptoms virtually disappear under proper sawtooth ventilation. Tomato plants maintain strong stem growth and consistent fruit set even during peak summer months. Leafy vegetables show no tip burn or premature bolting. Herbs maintain their essential oil content and aromatic qualities that command premium prices. These quality improvements often justify 25-40% higher selling prices compared to heat-stressed crops from conventional structures.

| Crop Response | Traditional Greenhouse | Sawtooth Greenhouse | Improvement |

|---|---|---|---|

| Tomato Fruit Set | 60% | 85% | +42% |

| Lettuce Bolting Rate | 35% | 8% | -77% |

| Herb Essential Oil Content | 2.1% | 3.4% | +62% |

| Overall Yield Quality | 65% marketable | 92% marketable | +42% |

| Harvest Consistency | Seasonal | Year-round | Continuous |

The worker comfort benefits cannot be ignored. Greenhouse work becomes dangerous when internal temperatures exceed 42°C. Heat exhaustion reduces productivity and increases safety risks. Sawtooth ventilation creates comfortable working conditions that improve labor efficiency and reduce turnover. Happy, comfortable workers provide better crop care, contributing to overall production quality.

Slashing Energy Bills: The Financial Case for a Sawtooth Greenhouse?

Mechanical ventilation and cooling systems consume massive amounts of electricity while requiring constant maintenance and eventual replacement.

Sawtooth greenhouses eliminate 80-95% of ventilation energy costs while reducing initial construction expenses through simpler electrical systems, delivering payback periods of 12-18 months compared to mechanically ventilated structures.

Dramatic energy savings with natural ventilation systems.

Calculating Real Energy Savings

Let me break down actual numbers from our recent installations. A 2,000-square-meter conventional greenhouse in Vietnam requires eighteen exhaust fans running 12 hours daily during hot seasons. At 0.75kW per fan and local electricity rates of $0.08 per kWh, daily energy costs reach $12.96. Annual ventilation electricity costs total $4,730 – and this excludes cooling systems, which could double these figures.

The same-sized sawtooth greenhouse requires zero energy for basic ventilation. Even adding supplemental circulation fans for extreme conditions uses just four small fans totaling 1.2kW, costing $1.15 daily or $420 annually. The energy savings of $4,310 per year pay for the sawtooth roof premium within fifteen months.

| System Type | Initial Cost Premium | Annual Energy Cost | Maintenance Cost | 5-Year Total Cost |

|---|---|---|---|---|

| Conventional + Fans | $0 (baseline) | $4,730 | $850 | $27,900 |

| Sawtooth Natural | +$6,500 | $0 | $150 | $7,250 |

| Sawtooth + Minimal Fans | +$7,200 | $420 | $200 | $10,300 |

Maintenance savings add substantial value. Mechanical ventilation systems require regular fan motor replacement, belt adjustments, and electrical repairs. We track maintenance costs across hundreds of installations – mechanically ventilated greenhouses average $850 annually in ventilation system upkeep. Natural ventilation requires only occasional vent adjustment and minimal structural maintenance, typically under $150 yearly.

The reliability factor proves invaluable. Mechanical systems fail during the hottest weather when you need them most. Power outages, motor failures, and control system problems can destroy entire crops within hours. Natural ventilation works regardless of electrical supply, providing security that protects your investment even during infrastructure failures common in developing regions.

Sawtooth vs. Forced-Air Systems: Which is Right for Your Tropical Farm?

Choosing the wrong ventilation system wastes money and creates ongoing operational problems that reduce profitability.

Sawtooth ventilation excels in consistently hot climates with minimal temperature variation, while forced-air systems work better in regions requiring precise climate control or dealing with extreme humidity conditions.

Choosing the optimal ventilation system for your conditions.

Decision Factors for System Selection

Climate consistency determines which system works best. Sawtooth ventilation performs excellently in tropical regions with steady temperatures and predictable weather patterns. If your location experiences consistent 28-35°C temperatures with moderate humidity, natural ventilation provides ideal conditions. However, areas with extreme temperature swings or very high humidity may benefit from supplemental mechanical systems.

Crop requirements influence the decision significantly. Heat-tolerant vegetables like peppers, eggplants, and tropical leafy greens thrive under sawtooth ventilation. Temperature-sensitive crops requiring precise climate control – such as European lettuce varieties or premium cut flowers – may need the additional control that forced-air systems provide. Consider your target markets and price points when making this evaluation.

| Factor | Sawtooth Advantage | Forced-Air Advantage |

|---|---|---|

| Operating Costs | Zero energy for basic ventilation | Precise temperature control |

| Reliability | No mechanical failures | Consistent performance |

| Initial Investment | Lower electrical requirements | Better for sensitive crops |

| Maintenance | Minimal upkeep needed | Professional service available |

| Climate Adaptability | Excellent for stable hot climates | Handles variable conditions |

Economic considerations often tip the balance. Calculate your local electricity costs, system maintenance expenses, and crop value premiums. If energy costs exceed $0.06 per kWh and you grow moderate-value crops, sawtooth ventilation typically provides better returns. Premium crop producers targeting export markets might justify forced-air systems through higher selling prices and consistent quality.

Your technical expertise affects system choice. Sawtooth greenhouses require minimal technical knowledge – adjust vents seasonally and maintain structural components. Forced-air systems need regular calibration, filter changes, and troubleshooting skills. Consider your available labor skills and local technical support when deciding between systems.

Hybrid Approaches for Optimal Results

Many successful operations combine both approaches. We design sawtooth roofs with minimal forced-air backup for extreme conditions. This hybrid system operates naturally 80-90% of the time while providing mechanical assistance during weather extremes or critical crop periods. The result combines low operating costs with production security.

A typical hybrid installation uses natural ventilation as the primary system with small circulation fans activated only when temperatures exceed preset limits. This approach captures most energy savings while maintaining crop protection during unusual weather events. The backup fans cost less than full mechanical systems while providing peace of mind for valuable crops.

Conclusion

Sawtooth greenhouses harness natural physics to solve tropical ventilation challenges, delivering zero-energy cooling, improved crop quality, and substantial cost savings that make greenhouse farming profitable in the world’s hottest climates.