Single annual harvests limiting your revenue potential? Light pollution destroying your flowering cycles and reducing crop potency in photoperiod-sensitive plants?

Automated blackout systems enable precise photoperiod control that triggers flowering on demand, allowing 2-3 harvests annually instead of one. These systems increase revenue by 150-200% while improving crop quality and consistency.

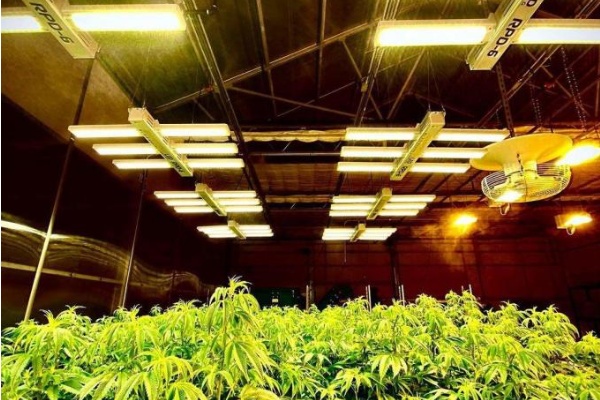

After installing blackout systems for commercial growers across diverse markets, I’ve witnessed the dramatic revenue transformation these systems create. Operations that struggled with single seasonal harvests now run continuous production cycles, with some facilities achieving four complete harvests annually while maintaining premium quality standards.

How Automated Blackout Curtains Trigger Flowering on Command

Photoperiod manipulation gives growers complete control over plant reproductive cycles, eliminating dependence on natural seasonal changes that limit production schedules.

Automated blackout systems create artificial night periods by blocking 100% of light penetration, triggering flowering responses in photoperiod-sensitive crops regardless of natural daylight hours. This control enables year-round flowering cycles and precise harvest timing.

Understanding Photoperiod Biology

Photoperiod-sensitive plants evolved flowering responses tied to seasonal light changes that signal optimal reproductive timing. These plants measure night length rather than day length, with critical dark periods triggering hormonal changes that initiate flowering. Understanding this biology enables precise manipulation of reproductive cycles.

Short-day plants like cannabis require uninterrupted dark periods of 12 hours or more to trigger flowering. Even brief light exposure during the dark period can disrupt the flowering response, causing plants to revert to vegetative growth. This sensitivity demands blackout systems that achieve complete light exclusion.

Phytochrome proteins in plant tissues detect red and far-red light ratios that signal day and night transitions. These proteins control flowering hormones that determine when plants shift from vegetative to reproductive growth. Blackout systems manipulate these signals by creating artificial night periods.

Critical photoperiods vary between crop varieties, with some requiring 10-hour nights while others need 14 hours of darkness. Professional blackout systems provide flexible timing that accommodates different varieties within the same facility, maximizing production diversity and market opportunities.

Flowering transition typically requires 7-14 days of proper photoperiod exposure before plants commit to reproductive growth. During this transition, consistent darkness becomes essential because any light interruption can delay or prevent flowering initiation.

Automation Precision Requirements

Light leak elimination requires blackout materials and installation methods that prevent even minimal light penetration. Professional systems achieve less than 0.1 lux light levels during blackout periods, compared to 50,000+ lux during normal daylight hours.

Timing accuracy becomes critical because photoperiod-sensitive plants respond to timing variations of just 15-30 minutes. Quality control systems maintain blackout schedules within 2-3 minutes of target times, ensuring consistent flowering responses across all plants.

Environmental coordination integrates blackout timing with heating, cooling, and ventilation systems to maintain optimal growing conditions during dark periods. Poor coordination can create temperature or humidity problems that stress plants during critical flowering transitions.

Motor reliability ensures blackout curtains operate consistently throughout multi-month flowering cycles. System failures during flowering can cause plants to revert to vegetative growth, destroying entire crop cycles and causing massive financial losses.

Emergency backup systems maintain blackout schedules during power outages or equipment failures. Battery backup systems can operate curtains for 8-12 hours, protecting crops during utility interruptions or emergency situations.

Maximizing Potency & Yields in Photoperiod-Sensitive Crops (Cannabis, Herbs, etc.)

Precise photoperiod control doesn’t just enable flowering – it optimizes plant chemistry and productivity that determine final crop value and market positioning.

Controlled light deprivation increases essential oil production, cannabinoid concentrations, and secondary metabolite development by 20-40% compared to natural photoperiods. This enhancement creates premium products that command higher market prices.

Optimizing Secondary Metabolite Production

Essential oil concentration increases dramatically when plants experience optimal photoperiod stress that triggers defensive compound production. Controlled light deprivation creates mild stress responses that enhance oil production without damaging plant health or reducing yields.

Cannabinoid profile optimization uses specific photoperiod timing to influence THC, CBD, and terpene ratios in cannabis crops. Precise darkness periods can increase THC concentrations by 15-25% while enhancing terpene diversity that improves flavor and therapeutic effects.

Herb potency enhancement works similarly across medicinal and culinary herbs where essential oils determine product value. Basil, oregano, and other culinary herbs show 30-50% increases in essential oil content when grown under controlled photoperiods compared to natural light cycles.

Anthocyanin development in colored varieties responds strongly to photoperiod manipulation combined with temperature control. Purple cannabis strains and colored herbs develop more intense pigmentation under controlled light cycles, creating premium visual appeal that supports higher pricing.

Harvest timing precision allows growers to schedule flowering completion for optimal market windows. Instead of harvesting when plants are ready, growers can time flowering to coincide with peak demand periods, maximizing revenue per crop cycle.

Yield Optimization Strategies

Multiple harvest scheduling uses staggered flowering initiation to create continuous harvest cycles. Instead of harvesting entire facilities simultaneously, growers can trigger flowering in sections, enabling weekly or bi-weekly harvests that smooth cash flow and labor demands.

Plant density optimization becomes possible when flowering timing is controlled rather than seasonal. Growers can pack more plants into growing spaces because they control when space becomes available through precise harvest timing.

Crop staging allows different varieties with varying flowering periods to finish simultaneously. Fast-flowering varieties can start photoperiod later than slow varieties, enabling coordinated harvests that optimize labor efficiency and processing capacity.

Quality consistency improves when environmental conditions remain stable throughout controlled flowering cycles. Natural photoperiods include seasonal temperature and humidity variations that affect crop quality. Controlled systems maintain optimal conditions year-round.

Genetic expression optimization uses consistent photoperiods to reveal true plant potential without environmental stress. Plants grown under optimal controlled conditions often exceed breeder specifications for yield and potency because they never experience growth-limiting stress.

From 1 Harvest to 3: Calculating the ROI of a Light Deprivation System

The financial transformation from single annual harvests to multiple controlled cycles creates compelling investment returns that justify blackout system costs within months.

Light deprivation systems typically cost $3-$8 per square foot installed but enable 200-300% revenue increases through multiple annual harvests. Most installations achieve complete payback within 6-12 months of operation.

Revenue Multiplication Mathematics

A typical outdoor cannabis operation produces one harvest annually, generating $15-$30 per square foot in revenue depending on market conditions and crop quality. Indoor operations with blackout systems can achieve 3-4 harvests annually, multiplying revenue potential to $45-$120 per square foot.

Investment costs for professional blackout systems range from $15,000-$40,000 for a 5,000 square foot greenhouse, including automated curtains, control systems, and installation. This represents $3-$8 per square foot of growing space, a modest investment compared to revenue potential.

Payback calculations become straightforward when comparing single versus multiple harvest revenues. A facility generating $75,000 annually from one harvest could produce $225,000 with three harvests. The additional $150,000 revenue easily justifies a $25,000 system investment within four months.

Operating cost increases remain minimal because blackout systems add little to ongoing expenses. Electricity consumption increases slightly for curtain motors, but this cost is negligible compared to lighting and climate control expenses that remain constant regardless of harvest frequency.

Quality premiums often accompany controlled production because consistent environmental conditions produce superior crops. Premium markets pay 20-50% more for consistent quality, adding another revenue stream that accelerates payback periods.

Advanced Financial Considerations

Cash flow improvements result from multiple harvests that generate revenue throughout the year instead of single large payments. This steady income stream supports better business planning and reduces seasonal cash flow problems that plague single-harvest operations.

Market timing advantages allow growers to target peak demand periods when prices are highest. Instead of harvesting when plants are ready, growers can time multiple harvests to coincide with holidays, festivals, or seasonal demand peaks.

Risk diversification spreads crop loss risk across multiple harvests instead of concentrating everything in single annual crops. Weather damage, pest problems, or market disruptions affect smaller portions of annual production when spread across multiple cycles.

Financing options for blackout systems often include equipment leasing or agricultural loans with favorable terms. The proven revenue increases make these systems attractive to lenders who understand the rapid payback potential.

Tax advantages may include accelerated depreciation for agricultural equipment and potential deductions for sustainable growing practices. Professional tax advice can optimize the financial benefits of blackout system investments.

5 Essential Features of a High-Performance Commercial Blackout System

Commercial blackout systems require specific capabilities that separate professional installations from basic light deprivation setups. These features determine system reliability and long-term profitability.

Professional blackout systems must provide 100% light exclusion, automated operation, environmental integration, emergency backup, and scalable expansion capabilities. Missing any of these features compromises crop quality and revenue potential.

Feature #1: Complete Light Exclusion

Light leak elimination requires specialized materials and installation techniques that achieve less than 0.1 lux during blackout periods. Even minimal light leaks can disrupt flowering in sensitive crops, causing reversion to vegetative growth that destroys entire crop cycles.

Blackout fabric specifications must include 100% opacity with reinforced edges that resist tearing and UV degradation. Professional fabrics use multi-layer construction with reflective surfaces that also provide insulation benefits during operation.

Sealing systems prevent light penetration at curtain edges, support structures, and penetrations for ventilation or electrical systems. Quality installations use brush seals, magnetic strips, and overlap designs that eliminate light leaks while allowing proper ventilation.

Track systems must maintain fabric tension and alignment throughout thousands of operating cycles. Professional tracks use heavy-duty materials with precision guides that prevent binding or fabric damage during operation.

Testing procedures verify light exclusion performance using calibrated light meters that detect even minimal leakage. Professional installations include commissioning tests that document complete light exclusion before system acceptance.

Feature #2: Precision Automated Controls

Timing accuracy within 2-3 minutes ensures consistent photoperiod delivery that maintains flowering responses across all plants. Manual systems cannot achieve this precision, making automation essential for commercial operations.

Programming flexibility allows different photoperiod schedules for various crops or growth stages within the same facility. Multi-zone control enables diverse production schedules that maximize facility utilization and revenue potential.

Environmental integration coordinates blackout timing with heating, cooling, and ventilation systems to maintain optimal growing conditions during dark periods. Poor integration can create temperature or humidity problems that stress plants.

Fail-safe operation includes backup systems that maintain blackout schedules during power outages or equipment failures. Battery backup systems protect crops during utility interruptions or emergency situations.

Remote monitoring enables system oversight from any location with internet access. This capability supports efficient operations management while providing peace of mind during critical flowering periods.

Feature #3: Robust Motor Systems

Motor sizing must handle fabric weight and wind loads throughout the expected service life without performance degradation. Undersized motors fail prematurely while oversized motors waste energy and increase installation costs.

Gear reduction systems provide the torque needed for smooth fabric operation while maintaining precise positioning accuracy. Quality gear systems operate quietly and require minimal maintenance over years of service.

Weather protection shields motors and control components from moisture, dust, and temperature extremes that cause premature failures. Professional installations include weatherproof enclosures rated for greenhouse environments.

Maintenance accessibility ensures technicians can service motors and drive components without disrupting growing operations. Hidden or hard-to-reach components increase maintenance costs and system downtime.

Feature #4: Environmental Compatibility

Ventilation coordination maintains air circulation during blackout periods without compromising light exclusion. Specialized vents and fan systems provide airflow while preventing light leaks that disrupt flowering.

Temperature management prevents overheating during blackout periods when solar gain is blocked but plant respiration continues. Integrated systems coordinate cooling with blackout timing to maintain optimal growing conditions.

Humidity control becomes critical during blackout periods when plant transpiration continues without solar-driven evaporation. Quality systems include dehumidification capabilities that prevent condensation and disease problems.

Structural integration ensures blackout systems work with existing greenhouse frameworks without compromising structural integrity. Professional installations include engineering analysis that verifies structural adequacy.

Feature #5: Scalable Expansion Design

Modular construction allows system expansion as operations grow without requiring complete replacement of existing equipment. This flexibility protects initial investments while supporting business growth.

Zone independence enables different operating schedules in various facility sections without interfering with each other. This capability maximizes production flexibility and crop diversity opportunities.

Control system compatibility ensures new sections integrate seamlessly with existing automation systems. Standardized interfaces prevent compatibility problems that plague mixed-vendor installations.

Power distribution planning accommodates future expansion without requiring electrical system upgrades. Proper planning prevents expensive retrofits when adding blackout systems to new growing areas.

Conclusion

Professional blackout systems transform photoperiod-sensitive crop production from seasonal limitations into year-round profit centers through precise flowering control and multiple annual harvests.