Water scarcity affects 40% of global agriculture. Your greenhouse irrigation choice determines crop success and profit margins. Wrong systems waste money and kill plants.

Commercial greenhouse irrigation systems range from $2-15 per square meter. Manual pipe systems offer flexibility for small operations. Drip irrigation saves 30-50% water. Subsurface systems reduce disease by 60%. Mobile sprinklers automate large facilities efficiently.

After 29 years in greenhouse technology, I’ve seen growers make costly irrigation mistakes. The right system transforms struggling operations into profitable enterprises. Let me share what works for different growing approaches.

Don’t Miss:——Commercial Greenhouse Materials Showdown: Polycarbonate vs Glass – Which Covering Will Maximize Your 2025 ROI?

You might like:——What is a Smart Greenhouse? The Ultimate Guide to Automated Growing

Manual Control Pipe Irrigation: A Flexible, Low-Investment Entry-Level Option?

Small budgets shouldn’t stop greenhouse dreams. Manual pipe systems offer affordable entry points. Many successful growers started with basic setups.

Manual pipe irrigation costs $2-4 per square meter. Systems use PVC pipes with manual valves. Growers control water timing and volume directly. Perfect for small operations under 1000 square meters with diverse crops.

Manual systems work best for soil cultivation and container growing. I remember visiting a tomato grower in Thailand who started with manual pipes. His 500-square-meter greenhouse used simple PVC networks with ball valves. He controlled each section manually based on plant needs.

The system flexibility amazed me. Different crop sections received different watering schedules. Seedlings got light misting. Mature plants received deep watering. He adjusted timing based on weather and growth stages.

Key Components and Setup Requirements

Manual pipe systems need basic components. Main supply lines connect to water sources. Distribution pipes carry water to growing areas. Control valves regulate flow to each section. End caps prevent water loss.

Installation requires minimal technical skills. Most growers handle setup themselves. Pipe sizing depends on greenhouse dimensions and crop water needs. Quarter-inch pipes work for small sections. Half-inch pipes serve larger areas.

| Component | Cost Range | Lifespan | Maintenance |

|---|---|---|---|

| PVC Pipes | $0.50-1.00/meter | 10-15 years | Low |

| Ball Valves | $2-5 each | 5-8 years | Medium |

| Fittings | $0.25-0.75 each | 10+ years | Low |

| Timers (optional) | $15-30 each | 3-5 years | Medium |

Labor costs stay low with manual systems. Growers spend 15-30 minutes daily on irrigation tasks. This hands-on approach helps beginners learn plant water needs. Many experienced growers still prefer manual control for specialty crops.

Water distribution stays uneven without careful management. Some plants get too much water. Others receive too little. Growers must walk through facilities regularly. They check soil moisture and plant health constantly.

Drip Irrigation and Micro-Sprinkler Tape: Water-Saving Features and Matching Different Crop Needs?

Water costs keep rising globally. Drip systems cut consumption by 30-50% compared to overhead watering. Smart growers invest in water-saving technology early.

Drip irrigation delivers water directly to plant roots through emitters. Micro-sprinkler tape creates fine mist patterns. Both systems reduce water waste and disease pressure. Installation costs $4-8 per square meter.

Drip systems excel in soil cultivation and container growing. I worked with a cucumber grower in Netherlands who switched from overhead sprinklers to drip irrigation. His water bills dropped 40% in the first season. Plant health improved dramatically.

The system delivered precise water amounts to each plant. Emitters released 2-4 liters per hour. Plants received consistent moisture without waterlogged soil. Root diseases decreased significantly.

Emitter Types and Flow Rates

Different emitters serve different purposes. Pressure-compensating emitters maintain consistent flow rates. Non-pressure-compensating emitters cost less but vary with pressure changes. Self-flushing emitters prevent clogging in dirty water.

Flow rates range from 0.5 to 8 liters per hour. Low-flow emitters work for seedlings and herbs. High-flow emitters serve large fruiting plants. Adjustable emitters allow fine-tuning for different growth stages.

Micro-sprinkler tape creates different spray patterns. Some create 180-degree semicircles. Others produce 360-degree full circles. Strip patterns work well for row crops. Misting patterns suit propagation areas.

| Emitter Type | Flow Rate | Best Use | Cost |

|---|---|---|---|

| Button Drippers | 2-4 L/hr | Tomatoes, Peppers | $0.15-0.25 |

| Micro-sprinklers | 10-40 L/hr | Leafy Greens | $0.50-1.00 |

| Misting Nozzles | 5-15 L/hr | Propagation | $0.75-1.25 |

| Adjustable Stakes | 0-8 L/hr | Mixed Crops | $1.00-2.00 |

Filtration becomes critical with drip systems. Particles clog small emitter openings. Sand filters remove large debris. Screen filters catch medium particles. Disc filters handle fine sediment. Some systems need multiple filter stages.

Maintenance requirements stay moderate. Growers flush lines weekly to prevent buildup. They replace clogged emitters monthly. System inspection takes 30-60 minutes weekly. Proper maintenance extends system life to 8-12 years.

Subsurface Drip Irrigation: Advanced Technology to Reduce Evaporation and Disease Risk?

Surface irrigation wastes water through evaporation. Wet foliage increases disease pressure. Subsurface systems solve both problems with underground water delivery.

Subsurface drip irrigation places emitters below soil surface. Water reaches roots directly without surface wetting. Evaporation drops 25-40%. Fungal diseases decrease 60%. Installation costs $6-12 per square meter.

Subsurface systems work best for soil cultivation and raised beds. I helped design a system for a bell pepper grower in Mexico. His previous overhead system caused constant bacterial spot outbreaks. Subsurface irrigation eliminated foliar diseases completely.

The buried lines delivered water 6-8 inches below surface. Roots grew toward moisture sources. Plants developed stronger root systems. Water use efficiency increased 35% compared to surface drip.

Installation Depth and Spacing Considerations

Proper depth prevents root intrusion and ensures effective water distribution. Shallow installations at 4-6 inches work for annual crops. Deeper installations at 8-12 inches serve perennial plants. Root barriers prevent damage to drip lines.

Emitter spacing depends on soil type and crop requirements. Sandy soils need closer spacing due to limited lateral water movement. Clay soils allow wider spacing because water spreads horizontally. Typical spacing ranges from 12-24 inches.

Line burial requires careful planning. Trenching machines create consistent depths. Hand digging works for small areas. Lines must slope slightly for proper drainage. Air vents prevent vacuum formation during system shutdown.

| Soil Type | Installation Depth | Emitter Spacing | Water Movement |

|---|---|---|---|

| Sandy | 4-6 inches | 12-18 inches | Vertical |

| Loamy | 6-8 inches | 18-24 inches | Balanced |

| Clay | 8-10 inches | 24-30 inches | Horizontal |

| Raised Beds | 4-6 inches | 12-16 inches | Contained |

System monitoring becomes more challenging with buried lines. Soil moisture sensors help track water levels. Tensiometers measure soil water tension. Visual plant indicators show stress before damage occurs.

Maintenance requires specialized tools. Pressure testing identifies line breaks. Flushing removes accumulated debris. Root intrusion may require line replacement every 5-7 years. Proper installation extends system life significantly.

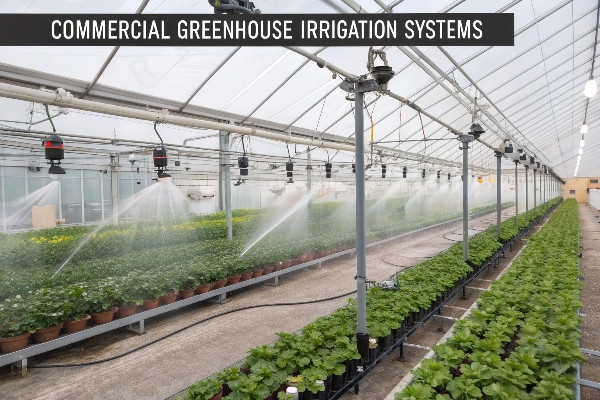

Mobile Overhead Sprinklers: Automation, Fertigation, and Their Use in Large Greenhouses?

Large greenhouses need efficient irrigation coverage. Fixed systems require extensive piping networks. Mobile sprinklers reduce infrastructure costs while providing uniform coverage.

Mobile overhead sprinklers move along tracks or cables. Systems cover 1000-5000 square meters per unit. Automation reduces labor costs 70%. Fertigation integration delivers nutrients with water. Installation costs $8-15 per square meter.

Mobile systems excel in large soil cultivation and hydroponic operations. I designed a system for a lettuce grower in California with 2 hectares under glass. Three mobile units covered the entire facility. Each unit irrigated 6000 square meters in 45 minutes.

The automated system operated on preset schedules. Sensors triggered irrigation based on environmental conditions. Nutrient injection systems delivered precise fertilizer concentrations. Labor requirements dropped from 8 hours daily to 1 hour weekly.

Track Systems and Movement Mechanisms

Rail-mounted systems provide precise positioning and smooth operation. Aluminum tracks resist corrosion in humid environments. Steel tracks offer durability for heavy-duty applications. Track spacing typically ranges from 6-12 meters.

Cable systems cost less but require more maintenance. Tensioned cables support sprinkler carriages. Pulleys and motors provide movement power. Cable stretch affects positioning accuracy over time.

Drive mechanisms vary by manufacturer and application. Electric motors offer quiet operation and precise control. Hydraulic systems provide high power for large units. Pneumatic systems work well in explosive environments.

| System Type | Coverage Area | Speed | Power Requirements |

|---|---|---|---|

| Rail-mounted | 3000-8000 m² | 2-5 m/min | 2-5 kW |

| Cable-driven | 1000-4000 m² | 1-3 m/min | 1-3 kW |

| Self-propelled | 500-2000 m² | 0.5-2 m/min | 0.5-2 kW |

| Stationary Boom | 2000-6000 m² | 3-8 m/min | 3-8 kW |

Fertigation systems integrate seamlessly with mobile units. Injection pumps deliver precise nutrient concentrations. Mixing tanks ensure uniform distribution. EC and pH sensors monitor solution quality continuously.

Programming capabilities allow complex irrigation schedules. Different zones receive different treatments. Seasonal adjustments accommodate changing crop needs. Weather stations trigger automatic schedule modifications.

Hydroponic Systems: NFT, DWC, and Specialized Circulation Requirements?

Hydroponic growing eliminates soil completely. Plants grow in nutrient solutions or inert media. These systems need specialized circulation and monitoring equipment.

Hydroponic systems circulate nutrient solutions continuously. NFT uses thin film flow. DWC suspends roots in oxygenated solution. Ebb and flow systems flood and drain periodically. Circulation costs $10-25 per square meter.

Hydroponic systems require precise environmental control. I installed an NFT system for a strawberry grower in Japan. The system used 90% less water than soil growing. Yields increased 300% per square meter.

The nutrient film technique used sloped channels. Thin nutrient films flowed past plant roots. Excess solution returned to reservoirs for recirculation. Pumps operated continuously to maintain flow.

NFT Channel Design and Flow Rates

Channel slope affects flow velocity and nutrient distribution. Optimal slopes range from 1:30 to 1:40. Steeper slopes increase flow velocity but may cause erosion. Gentler slopes risk stagnation and algae growth.

Flow rates must match crop requirements and channel dimensions. Leafy greens need 1-2 liters per minute per channel. Fruiting crops require 2-4 liters per minute. Flow rates adjust based on plant size and environmental conditions.

Channel materials affect system longevity and plant health. PVC channels resist corrosion and clean easily. Polystyrene channels insulate roots from temperature fluctuations. Stainless steel channels last longest but cost more.

| Crop Type | Channel Width | Flow Rate | Slope Ratio |

|---|---|---|---|

| Lettuce | 4-6 inches | 1-2 L/min | 1:30 |

| Herbs | 4-6 inches | 1-2 L/min | 1:35 |

| Strawberries | 6-8 inches | 2-3 L/min | 1:40 |

| Tomatoes | 8-10 inches | 3-4 L/min | 1:30 |

Deep water culture systems submerge roots completely. Air pumps oxygenate nutrient solutions continuously. Dissolved oxygen levels must stay above 5 ppm. Root rot develops quickly in poorly oxygenated solutions.

Reservoir management becomes critical in recirculating systems. Nutrient concentrations change as plants absorb elements. pH levels drift over time. Automated dosing systems maintain optimal conditions.

Ebb and Flow Systems: Timing, Drainage, and Flood Cycle Management?

Ebb and flow systems flood growing areas periodically. Plants sit in growing media above flood levels. Timed pumps deliver nutrient solutions. Gravity drainage returns excess solution to reservoirs.

Ebb and flow systems flood growing tables 2-8 times daily. Flood duration ranges from 10-30 minutes. Growing media holds moisture between cycles. System costs $8-18 per square meter including tables and pumps.

Ebb and flow works well for container crops and propagation. I designed a system for a herb grower in Germany. The system used existing greenhouse tables. Flood cycles delivered precise nutrient amounts without overwatering.

The timer-controlled pumps flooded tables to predetermined levels. Overflow fittings prevented overfilling. Drainage systems returned solution to reservoirs within 5 minutes. Plants received consistent moisture without waterlogged roots.

Flood Timing and Duration Optimization

Flood frequency depends on crop type, growth stage, and environmental conditions. Seedlings need frequent light floods. Mature plants require less frequent heavy floods. Hot weather increases flood frequency. Cool conditions reduce watering needs.

Flood duration affects nutrient uptake and root health. Short floods of 5-10 minutes work for fine media. Longer floods of 15-30 minutes suit coarse media. Excessive flood duration causes root damage and nutrient waste.

Drainage speed prevents root suffocation. Proper drainage completes within 5 minutes after pump shutdown. Slow drainage indicates clogged outlets or undersized drains. Fast drainage may indicate oversized drains or pump problems.

| Growing Media | Flood Duration | Frequency | Drainage Time |

|---|---|---|---|

| Rockwool | 5-10 minutes | 4-6 times/day | 2-3 minutes |

| Perlite | 10-15 minutes | 3-5 times/day | 3-5 minutes |

| Expanded Clay | 15-20 minutes | 2-4 times/day | 1-2 minutes |

| Coco Coir | 10-15 minutes | 3-6 times/day | 3-4 minutes |

Table design affects flood uniformity and drainage efficiency. Level tables ensure even water distribution. Sloped tables improve drainage but create uneven moisture zones. Raised edges prevent spillage during floods.

Pump sizing must match table volume and flood timing requirements. Undersized pumps extend flood duration unnecessarily. Oversized pumps waste energy and stress plants. Variable speed pumps optimize performance across different conditions.

Conclusion

Irrigation system selection determines greenhouse success and profitability. Manual systems offer flexibility for beginners. Drip irrigation saves water and reduces disease. Subsurface systems maximize efficiency. Mobile sprinklers automate large operations. Hydroponic systems eliminate soil limitations completely.