You want to grow crops all year round. High energy bills and low yields from old greenhouses hurt your profit. You need a high-tech system that works smarter.

The financial success of your commercial greenhouse farm relies on smart investment in a high-quality structure, like the stable Venlo style, and efficient hydroponic systems. These choices help maximize crop yield, reduce labor costs, and ensure a strong Return on Investment (ROI) over many years of operation.

We know that choosing the right greenhouse is a huge business decision. You need a structure that is strong, efficient, and helps your plants grow perfectly. Let us break down the costs and show you why the best structure is the cheapest in the long run.

The Financial Breakdown: Commercial Hydroponic Glass Greenhouse Cost Per Square Meter?

You see different prices for greenhouses. You worry about spending too much money for something that does not last. You need a clear cost breakdown to plan your budget well.

A commercial hydroponic glass greenhouse typically costs between $80 to $200 per square meter, depending on the technology level and local construction costs. This price usually includes the Venlo structure, glass cladding, basic ventilation, and the initial concrete foundation. Highly automated systems, like advanced hydroponics or CO2 enrichment, will increase this total investment.

Dive Deeper: What Affects the Final Price?

The final price of your greenhouse is like a recipe with many ingredients. The main ingredient is the Structure Type. For example, the Venlo style uses less steel but is very strong. This saves money on materials.

Next is the Cladding Material. Glass costs more than Polycarbonate (PC) sheets. But glass lets in more light and lasts longer. This is better for your plants and your long-term profits.

Then you have Internal Systems. Does your greenhouse have simple fans or a smart computer that controls everything? Automated systems cost more at the start. However, they save a lot of money on labor and energy bills later. For example, our CFGET team started in 1996. We have almost 30 years of experience. We always advise our partners in Europe and North America to invest in high-tech systems. They meet strict sustainability rules and need less staff. We also offer highly cost-effective solutions for Southeast Asian growers who need fast installation and humid environment optimization. Choosing the right parts is the key to a good price.

| Component | Cost Impact | Why It Matters |

|---|---|---|

| Structure (Venlo vs. Arch) | High | Venlo is strong and uses less material, saving steel costs. |

| Cladding (Glass vs. PC) | Medium | Glass lasts 30+ years and offers the best light transmission. |

| Foundation (Depth/Material) | Low | Strong foundation is needed for heavy wind and snow loads. |

| Automation Level | Very High | This determines labor savings and climate control precision. |

ROI Calculator: Projecting Yields for Tomato & Lettuce in High-Tech Glasshouses?

You know the cost, but you do not know the profit. It feels risky to invest millions without a clear profit plan. You need real data on how quickly your investment will pay for itself.

The Return on Investment (ROI) for high-tech hydroponic glasshouses usually falls between 4 to 7 years, depending on the crop and market price. High-value crops like hydroponic tomatoes or specialty lettuce can yield 10 to 15 times more per square meter compared to traditional farming. This rapid increase in production accelerates your profit timeline.

Dive Deeper: How Does Technology Maximize Your Profit?

Technology does not just make farming easier. It makes farming much more predictable and profitable. This is the big difference between traditional farming and high-tech greenhouses.

In a traditional farm, you worry about the weather, pests, and soil quality. These things can cut your yield by half in one season. In a high-tech glasshouse, you control everything. The hydroponic system gives the plants the exact amount of food and water they need, right to their roots. This prevents waste and makes plants grow faster and healthier. Our CFGET environmental control systems, which we use globally, ensure this precision. They adjust the temperature, humidity, and CO2 level automatically. This is especially important for our clients in Central Asia who face extreme temperature swings. A steady environment means less stress for plants and more yield for you.

When you grow more per square meter, the price you paid for the greenhouse structure quickly starts to look small. For example, some advanced growers achieve 60 kg of tomatoes per square meter annually in a high-tech glasshouse. This high production number is the most important factor in a good ROI.

Engineering Excellence: Venlo Type Glass Greenhouse Structure Details and Stability?

You need a strong building. You have seen older greenhouses collapse from heavy snow or strong wind. You must choose a time-tested and certified structure that offers superior stability.

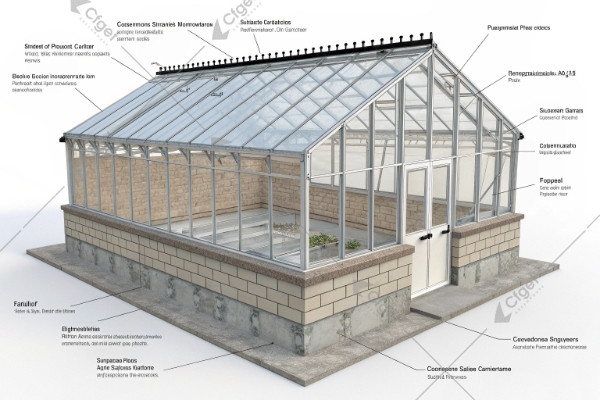

The Venlo-type glass greenhouse structure is the industry standard for stability and light transmission. It features a unique truss design with multiple roof ridges that efficiently handle heavy wind loads and distribute snow weight evenly. Its narrow ridge allows for efficient natural ventilation and maximizes the amount of sunlight that reaches the crops.

Dive Deeper: Why Venlo is the Global Standard for Stability?

The Venlo style was developed a long time ago in the Netherlands. It became popular because it solves three big problems.

First, Strength. The structure uses smaller, lightweight steel parts that form very strong triangles, called trusses. Trusses distribute weight very well. This makes the greenhouse very safe against heavy snow in places like Canada or strong winds in coastal areas. Our design team at CFGET uses the latest engineering software. We make sure every Venlo greenhouse meets or exceeds local building codes in over 20 countries. We focus on durability because our clients need long-term profitable goals.

Second, Light. The Venlo roof has narrow ridges and large glass panels. This lets in the maximum amount of light, which is food for your plants. More light means more yield.

Third, Ventilation. The roof is designed to open easily and efficiently. Hot, stale air rises and leaves quickly through the roof vents. This natural process saves a lot of money on cooling fans. This is a vital feature for our partners in humid climates like Southeast Asia. We provide not only the structure but also the technical support for these important design choices. A stable and smart structure protects your investment and your plants for many years.

From Design to Harvest: A Complete Multi-span Plastic Film Greenhouse Turnkey Solution?

You want to buy a complete farm, not just pieces. You do not want to manage many different suppliers for structure, cooling, and planting systems. You need one trusted partner who delivers a ready-to-use farm.

A multi-span plastic film greenhouse turnkey solution means one provider handles everything from the initial design and raw material manufacturing to the final installation and technical training. This approach is faster, cheaper, and ensures all parts of the greenhouse—from the structure to the irrigation system—work perfectly together as a unified system.

Dive Deeper: What Does ‘Turnkey’ Really Mean for Growers?

The word "turnkey" is very important for commercial growers. It means you get the keys to a working operation. You just need to "turn the key" and start planting.

When you work with a company like CFGET, we take care of all the complex steps. We design the greenhouse to fit your land and your crop. We manufacture the steel and plastic film in our factory, where we control the quality very closely. This is the full-service guarantee that our clients value highly.

A turnkey solution avoids mistakes. If you use one company for the structure and another for the hydroponics, they might not fit well together. Our approach makes sure the large multi-span structure and the high-tech interior are a perfect match. We even provide technical training for your staff. This ensures you can run the greenhouse efficiently from the very first day. We give you a single point of contact and accountability for the entire project. This saves time, avoids headaches, and ensures long-term profitable operation.

Conclusion

Choosing the right commercial greenhouse means looking past the initial cost. Focus on stability, high yield, and a trusted turnkey partner like us. This ensures fast ROI and long-term farming success.