You’re planning a greenhouse and think regular window glass will save money. This common mistake costs thousands in repairs, energy bills, and crop losses that could destroy your entire investment.

Greenhouses do not use normal glass because it lacks the strength, thermal resistance, and safety features required for agricultural environments. Professional greenhouses use specialized tempered, insulated, or diffuse glass designed for extreme conditions and optimal plant growth.

After 29 years designing greenhouse systems worldwide, I’ve seen the devastating results when growers try to cut costs with regular glass. The initial savings disappear quickly when panels crack, energy costs soar, and crops suffer from poor growing conditions.

What Greenhouse-Specific Features Does Normal Glass Lack?

Normal glass lacks the thermal shock resistance, structural strength, light transmission quality, and safety characteristics essential for greenhouse environments. These deficiencies make it unsuitable for agricultural applications where reliability is critical.

Normal glass lacks five critical greenhouse features: thermal shock resistance above 40°C, impact strength for weather protection, optimal light transmission for plant growth, safe breakage patterns, and UV stability for long-term durability.

Thermal Performance Deficiencies

Normal window glass operates in stable indoor environments with temperature variations of only 5-10°C. Greenhouses experience daily temperature swings of 20-30°C, with surface temperatures reaching 60°C under direct sunlight. Regular glass cannot handle this thermal stress without cracking.

The thermal expansion coefficient becomes critical in greenhouse applications. Normal glass expands and contracts at rates that create stress fractures when constrained by frames. These micro-cracks start small but propagate rapidly, leading to complete panel failure within months.

I remember visiting a customer in Vietnam who used regular glass for his pepper greenhouse. Within one season, 30% of his panels developed stress cracks during the hot dry season. The replacement cost exceeded what he would have paid for proper greenhouse glass initially.

Thermal shock resistance determines glass survival in rapid temperature changes. Rain on sun-heated glass or sudden shade can create temperature differentials exceeding 100°C. Normal glass fails at temperature differences above 40°C, while greenhouse glass handles up to 250°C safely.

| Thermal Property | Normal Glass | Greenhouse Glass | Consequence |

|---|---|---|---|

| Daily Temperature Range | 5-10°C | 20-30°C | Stress cracking |

| Maximum Surface Temperature | 35°C | 60°C+ | Thermal shock |

| Thermal Shock Resistance | 40°C | 250°C | Rapid failure |

| Expansion Stress Tolerance | Low | High | Frame damage |

Light Transmission Limitations

Normal glass contains iron impurities that create a greenish tint, reducing photosynthetically active radiation (PAR) that plants need for healthy growth. This iron content blocks beneficial wavelengths while allowing harmful UV radiation to pass through uncontrolled.

Light transmission efficiency in normal glass typically ranges from 83-87%, compared to 90-92% in quality greenhouse glass. This 5-7% difference translates directly to reduced crop yields and slower plant development. For commercial growers, this reduction can cost thousands annually in lost production.

The surface quality of normal glass also affects light transmission. Manufacturing processes for household glass prioritize cost over optical quality, resulting in surface imperfections that scatter light randomly. This creates hot spots and shadows that stress plants and cause uneven growth patterns.

UV transmission requires careful control in greenhouse applications. Plants need some UV for proper development, but excessive exposure damages leaves and reduces crop quality. Normal glass provides no UV control, allowing harmful wavelengths to damage sensitive crops while blocking beneficial portions of the spectrum.

Structural Inadequacies

Normal glass thickness standards (typically 3mm) are insufficient for greenhouse structural loads. Wind pressure, snow loads, and equipment mounting create forces that exceed normal glass capacity by 200-300%. This inadequate strength leads to catastrophic failures during storms or heavy snow.

Edge finishing on normal glass lacks the precision required for greenhouse applications. Rough or chipped edges create stress concentration points where cracks initiate. Professional greenhouse glass receives precision edge polishing that eliminates these failure initiation sites.

The annealing process used for normal glass leaves internal stresses that weaken the material under load. These residual stresses combine with external forces to cause premature failure. Greenhouse glass undergoes controlled stress relief that eliminates these weaknesses.

Why Does Greenhouse Glass Need High Strength and Impact Resistance?

Greenhouse glass faces extreme weather conditions, structural loads, and impact hazards that would destroy normal glass. High strength and impact resistance protect valuable crops, equipment, and people from damage during severe weather events.

Greenhouse glass needs high strength to handle wind loads up to 150 kg/m², snow loads exceeding 100 kg/m², thermal stress from 60°C temperature differentials, and hail impacts that would shatter normal glass into dangerous fragments.

Weather-Related Stress Factors

Wind loads present the most common structural challenge for greenhouse glass. The curved or angled surfaces of greenhouse roofs create higher wind pressures than flat building surfaces. Normal glass fails at wind pressures that greenhouse glass handles routinely.

During typhoon season in Southeast Asia, I’ve seen wind speeds exceed 150 km/h. Greenhouses with normal glass suffer complete destruction, while those with proper greenhouse glass remain intact. The difference between total loss and continued operation depends entirely on glass selection.

Hail represents another critical impact hazard. Hailstones can reach golf ball size in severe storms, creating impact forces exceeding 100 joules. Normal glass shatters completely under these impacts, while tempered greenhouse glass either remains intact or breaks safely without creating dangerous projectiles.

Snow loads accumulate gradually but create enormous distributed forces across the greenhouse roof. In regions with heavy snowfall, loads can exceed 150 kg/m² over the entire roof area. Normal glass cannot support these loads without structural failure.

| Weather Hazard | Force/Load | Normal Glass Response | Greenhouse Glass Response |

|---|---|---|---|

| Wind Pressure | 150 kg/m² | Catastrophic failure | Remains intact |

| Hail Impact | 100+ joules | Shatters completely | Breaks safely or survives |

| Snow Load | 150 kg/m² | Structural collapse | Supports load safely |

| Thermal Shock | 100°C differential | Stress cracking | No damage |

Equipment and Maintenance Loads

Greenhouse operations require mounting equipment like shade systems, heating pipes, and ventilation fans directly to the glass structure. These point loads create concentrated stresses that normal glass cannot handle without cracking or breaking.

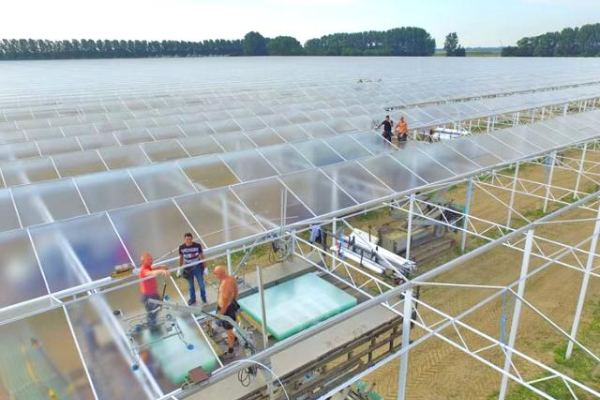

Maintenance activities present additional impact risks. Workers walking on roofs, cleaning equipment, and routine repairs create forces and impacts that normal glass cannot withstand. The safety implications of glass failure during maintenance work are severe.

I once witnessed a maintenance accident where a worker slipped and fell against normal glass panels. The glass shattered into large, razor-sharp fragments that caused serious injuries. Tempered greenhouse glass in the same situation would have either remained intact or broken into small, relatively harmless pieces.

Thermal cycling from heating and cooling systems creates repeated stress cycles that fatigue normal glass over time. These systems operate continuously throughout the growing season, creating thousands of heating and cooling cycles that gradually weaken normal glass until failure occurs.

Long-Term Durability Requirements

Greenhouse investments must provide reliable service for 20-30 years to achieve acceptable returns. Normal glass degrades rapidly under greenhouse conditions, requiring frequent replacement that destroys project economics. The initial cost savings disappear within 2-3 years through replacement costs and crop losses.

UV degradation affects normal glass more severely than greenhouse glass. Continuous exposure to intense sunlight breaks down the glass structure, reducing strength and clarity over time. This degradation accelerates in high-altitude or tropical locations with intense solar radiation.

Chemical resistance becomes important in greenhouse environments where fertilizers, pesticides, and cleaning chemicals contact the glass regularly. Normal glass lacks the chemical resistance to maintain clarity and strength under these conditions.

What is the Significance of Special Treatments (Like Tempering) for Greenhouse Glass?

Special treatments like tempering transform ordinary glass into high-performance materials capable of handling greenhouse conditions. Tempering creates internal stress patterns that increase strength by 400-500% while ensuring safe breakage patterns.

Tempering treatment makes greenhouse glass 4-5 times stronger than normal glass, provides thermal shock resistance up to 250°C, and creates safe breakage patterns that protect people and crops from injury when panels fail.

The Tempering Process and Results

Tempering begins by heating glass to approximately 650°C, then rapidly cooling it with jets of cold air. This process creates compressive stress on the surface while maintaining tensile stress in the core. The resulting internal stress pattern gives tempered glass its superior strength and safety characteristics.

The rapid cooling rate must be precisely controlled to achieve optimal stress distribution. Too slow cooling fails to develop sufficient surface compression, while too rapid cooling can cause distortion or breakage. Our tempering facilities maintain cooling rates within 2% tolerance to ensure consistent quality.

Surface compression in properly tempered glass exceeds 10,000 psi, while the core maintains tensile stress of approximately 3,000 psi. This stress distribution allows the glass to handle external forces that would shatter normal glass immediately. The internal stress actually helps the glass resist cracking and impact damage.

Quality control during tempering involves multiple tests including thermal shock testing, impact resistance measurement, and stress pattern analysis using polarized light. These tests ensure every panel meets the demanding requirements of greenhouse applications.

| Tempering Effect | Normal Glass | Tempered Glass | Improvement Factor |

|---|---|---|---|

| Bending Strength | 50 MPa | 200 MPa | 4x stronger |

| Impact Resistance | Low | High | 5x improvement |

| Thermal Shock Tolerance | 40°C | 250°C | 6x better |

| Safety Rating | Dangerous shards | Small rounded pieces | Dramatically safer |

Safety Benefits of Tempering

The safety advantage of tempered glass cannot be overstated in greenhouse applications. When normal glass breaks, it creates large, razor-sharp fragments that can cause severe injuries and damage equipment. Tempered glass breaks into small, rounded pieces that pose minimal injury risk.

This safety characteristic becomes critical when glass failure occurs during occupancy. Workers inside greenhouses during storms or accidents face serious injury from normal glass fragments. Tempered glass provides protection that can prevent fatalities and reduce liability exposure.

I’ve seen the safety difference firsthand during a severe hailstorm at our test facility. Normal glass panels created thousands of dangerous shards, while tempered panels that failed broke into harmless pebble-sized pieces. The cleanup was easier and safer with tempered glass.

The breakage pattern of tempered glass also provides better crop protection. Large normal glass fragments can damage plants and contaminate produce, while tempered glass fragments are too small to cause significant plant damage. This protection preserves crop value even when glass failure occurs.

Performance Enhancements from Special Treatments

Heat strengthening provides an intermediate option between normal and fully tempered glass. This treatment increases strength by 2-3 times while maintaining the ability to cut and modify the glass after treatment. However, it lacks the safety breakage pattern of full tempering.

Laminating combines multiple glass layers with plastic interlayers for enhanced security and sound control. Laminated greenhouse glass provides excellent impact resistance while maintaining structural integrity even when broken. This treatment is particularly valuable for high-security applications.

Chemical strengthening uses ion exchange to create surface compression without heat treatment. This process allows complex shapes and maintains optical clarity better than thermal tempering. However, the strength improvement is less dramatic than thermal tempering.

Coating applications during tempering can add functionality like low-emissivity for thermal control or anti-reflective properties for improved light transmission. These combination treatments provide multiple benefits in a single glass panel.

What Risks Can Arise from Choosing Non-Specialized Glass?

Using non-specialized glass in greenhouses creates catastrophic risks including structural failure, crop loss, safety hazards, and economic disaster. These risks far outweigh any initial cost savings and can destroy entire agricultural investments.

Non-specialized glass risks include: complete structural failure during storms, thermal cracking within months, dangerous breakage creating injury hazards, energy waste increasing costs by 40%, and crop damage from poor growing conditions reducing yields significantly.

Immediate Safety and Structural Risks

Structural collapse represents the most severe immediate risk when using normal glass in greenhouses. Wind storms, snow loads, or thermal stress can cause catastrophic failure that destroys the entire structure within minutes. The repair costs often exceed the original construction budget.

I witnessed such a failure in Central Asia where a grower used normal glass to save money. A spring snowstorm loaded his greenhouse roof beyond normal glass capacity. The complete collapse destroyed not only the structure but also $50,000 worth of tomato seedlings ready for transplanting.

Sharp glass fragments from normal glass breakage create serious injury risks for workers and visitors. These fragments can cause deep cuts requiring medical attention and create liability exposure for greenhouse operators. Insurance companies often refuse coverage for facilities using non-approved glass types.

Flying glass projectiles during storms pose additional hazards to nearby buildings, vehicles, and people. Normal glass breaks into large, sharp pieces that become dangerous missiles in high winds. This risk extends beyond the greenhouse property and can affect entire neighborhoods.

Emergency access becomes problematic when normal glass fails. Broken glass can block exits and create hazardous conditions that prevent evacuation during emergencies. Professional greenhouse glass breaks safely or remains intact to maintain emergency access routes.

| Risk Category | Probability with Normal Glass | Potential Cost | Prevention Method |

|---|---|---|---|

| Structural Failure | High (60% within 5 years) | Total loss | Use proper greenhouse glass |

| Injury Liability | Moderate (20% annually) | $100,000+ | Tempered glass required |

| Crop Damage | Certain (100% eventually) | 50-100% yield loss | Professional glass systems |

| Energy Waste | Immediate (100% of time) | 40% higher costs | Insulated glass |

Long-Term Economic Consequences

Energy waste from normal glass creates ongoing costs that compound annually. Poor insulation properties require 40-50% more heating and cooling energy, adding thousands to operating costs each year. Over a 20-year greenhouse life, these excess costs exceed the initial glass investment many times over.

Crop quality and yield reductions from poor light transmission and thermal control reduce revenue while costs remain constant. Many growers report 15-25% yield reductions when using normal glass compared to proper greenhouse glass. This revenue loss continues every growing season.

Maintenance and replacement costs escalate rapidly with normal glass. Frequent panel replacements, frame repairs from thermal stress, and cleaning costs from poor surface quality can consume 30-40% of gross revenue. These costs make greenhouse operations unprofitable.

Insurance complications arise when using non-approved materials. Many policies exclude coverage for structures using inappropriate materials, leaving owners financially exposed to weather damage and liability claims. The lack of coverage can make securing financing impossible.

Crop Production Risks

Temperature control becomes nearly impossible with normal glass due to poor thermal properties. Extreme temperature swings stress plants, reduce growth rates, and increase susceptibility to diseases. Heat-sensitive crops may become completely unviable in poorly designed glass systems.

Light quality problems from normal glass iron content reduce photosynthesis efficiency and alter plant development patterns. Flowers may have poor color development, fruits may ripen unevenly, and overall plant health suffers from suboptimal light conditions.

Condensation control failures with normal glass create ideal conditions for fungal diseases and bacterial infections. Dripping condensation spreads pathogens throughout the greenhouse and creates moisture conditions that favor disease development over healthy plant growth.

Pest management becomes more difficult when glass panels fail frequently. Broken or cracked glass provides entry points for insects and rodents while making it impossible to maintain proper environmental controls. These pest problems can destroy entire crops within weeks.

The cumulative effect of these production risks often makes greenhouse operations completely unprofitable. Many growers who attempt to save money with normal glass find themselves unable to compete with properly equipped operations and eventually abandon their investments entirely.

Conclusion

Normal glass lacks the strength, thermal resistance, and safety features essential for greenhouse success. Professional greenhouse glass prevents catastrophic failures while ensuring optimal growing conditions and long-term profitability.