28 Years of Expertise

Which Greenhouse is Right for Your Crops?

Selecting the Right Greenhouse Type and Facilities Based on Crop Needs and Environmental Conditions

Prepare for investment

We value every client’s investment and help you clarify goals and achieve success. Your success defines our value.

According to our statistics, 70% of greenhouse growers consider vegetable cultivation as their main business investment direction.

The cultivation of fruit crops is also an important choice for greenhouse growers, as their products have high economic value and market competitiveness.

Experienced growers explore unique paths in flower cultivation, which requires advanced techniques and professional management.

Medicinal crops have significant economic returns due to their high added value, and high-quality varieties are valuable.

Commercial Greenhouse

We focus on your investment plans, committed to leveraging our strengths to provide you with comprehensive solutions, helping you to face challenges with ease and ensure project success.

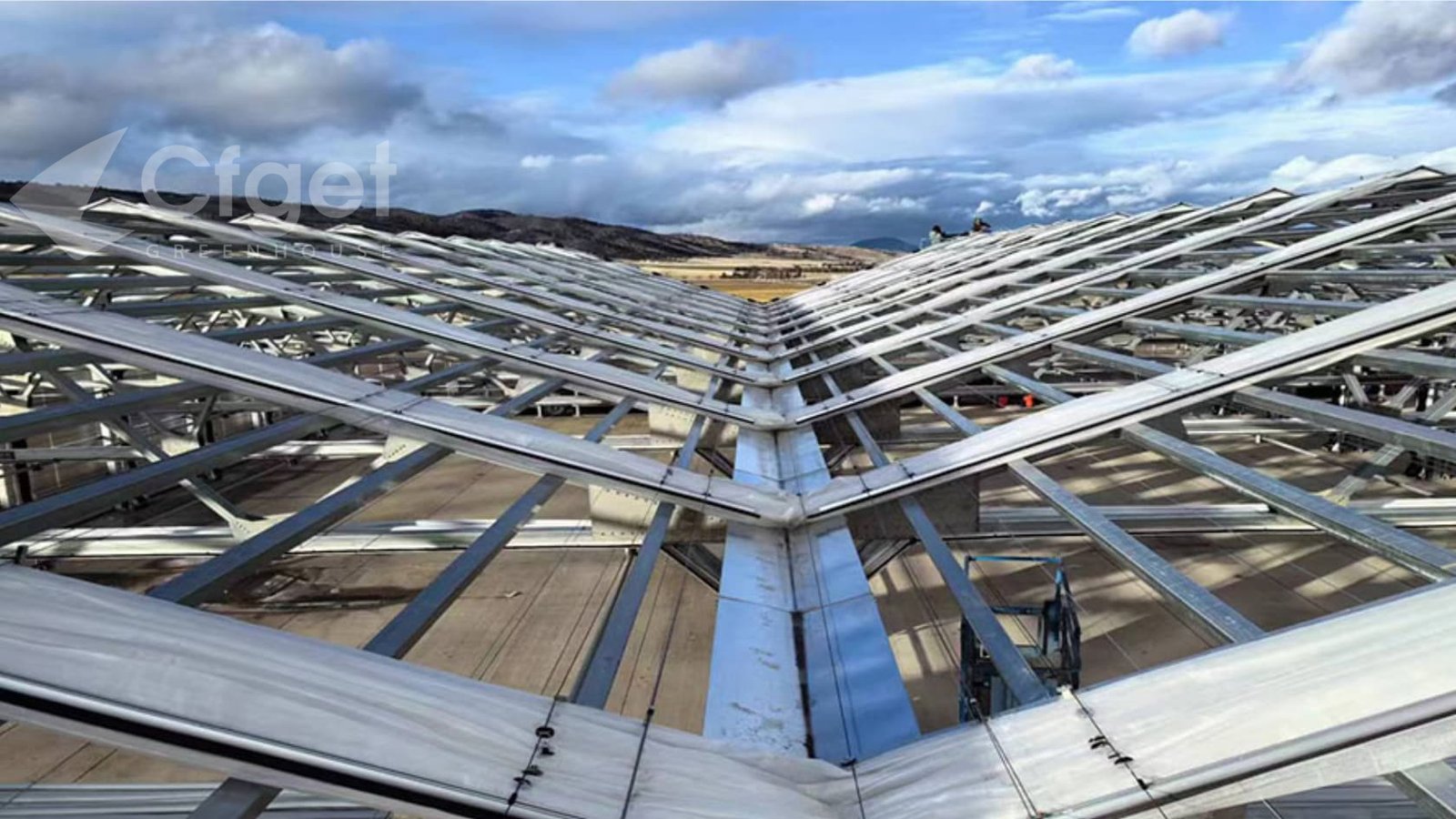

CFGET Greenhouse Structure

Let's Grow Together

Other Uses For Greenhouses

Other types of greenhouses are usually those with special needs or functions, such as multi-climatic environments, specific climatic conditions, or home gardening purposes.

Research & Education

Customized

Home Gardening

Customized Solutions to Your Projects

At CFGET, we are dedicated to providing customized solutions for all your greenhouse needs. Our expert team combines experience with advanced techniques to ensure your project is successful

- Greenhouse Design: Custom design for commercial, home gardening, research, and educational greenhouses

- Climate Control Solutions: Tailored climate control systems, including temperature, humidity, and lighting solutions

- Growing Systems: Hydroponic, substrate, organic farming, vertical, and layered systems designed to maximize space and efficiency

- Specialty Crop Solutions: Solutions for vegetables, fruits, floriculture, and medicinal plants

- Smart Auto & Control: Irrigation, fertilization, and smart automation system

More Than Just a Greenhouse Supplier

At CFGET, we pride ourselves on being more than just a greenhouse provider. Our dedication to customer success, combined with innovative solutions and experienced professionals, distinguishes us in the greenhouse industry

Greenhouse Solutions:

Design & Manufacturing:

Environmental Control :

Client-Centric Service

Greenhouse Solutions:Customized for Each Step of the Supply Chain

CFGET is dedicated to addressing the unique challenges at every stage, ensuring your growing operations thrive. We leverage our expertise to provide tailored solutions throughout your project.

- For Commercial Growers: We offer 12 types of greenhouse structures with customized environmental controls for optimal growing conditions. Our multi-span greenhouses are cost-effective and adaptable, suitable for large-scale production and seedling cultivation .

- Research Institutions: We provide custom research greenhouses with multi-zone climate control systems for accurate climate simulation, fostering exploration and innovation .

- Specialty Crop Cultivators: We design specialized greenhouses that cater to the unique environmental control needs of vegetables, fruits, flowers, and medicinal herbs, ensuring optimal quality and yield. We have served over 1200 clients across 52 crop categories .

- Distributors and Partners: We enhance regional support through local partnerships, committed to global agribusiness development. Our accumulated greenhouse product design patents have surpassed 30.

Greenhouse Solutions: A Comprehensive Buyer's Guide

In the greenhouse industry, CFGET is dedicated to providing tailored designs for various applications, including vegetables, fruits, floriculture, medicinal plants, research, and home gardening.

Table of Contents

Chapter 1

What is a Greenhouse?

A greenhouse is a structure designed to create an ideal environment for growing plants. It is typically made of transparent materials such as glass or plastic that allow sunlight to enter while retaining heat, thus creating a warm, stable climate inside.

This controlled environment helps extend the growing season, protect plants from adverse weather conditions, and can be adjusted to suit the needs of different plant species. Greenhouses can vary in size from small backyard structures to large commercial operations. They are commonly used in agriculture, horticulture, and gardening to cultivate vegetables, flowers, fruits, and other plants year-round.

Chapter 2

The Evolution of Greenhouses: A Historical Timeline

- 14-18th Century – In Europe, “giardini botanici” emerged in Italy. These early botanical gardens often included structures to protect exotic plants from harsher weather.

- 1619 – The Hortus Botanicus of Leiden, Netherlands, is built.

- 1680s – Greenhouses appeared in the Versailles, France.

- 1800s – The popularity of greenhouses increased among the wealthy in Europe and the United States. These were often elaborate structures made of glass and iron.

- Mid-1900s – The introduction of polyethylene film (plastic) revolutionized greenhouse construction, making them more affordable and accessible.

- Late 1900s – Development of environmental control systems (heating, cooling, ventilation) to optimize growing conditions.

- 2000s-Present – Growing adoption of advanced technologies such as hydroponics, LED lighting, and automated systems in commercial greenhouses.

Chapter 3

The basic structure and features of greenhouses

- Frame: The supporting structure determines the shape and strength, typically made of steel, aluminum, or wood, designed to withstand local climate conditions and cladding weight.

- Cladding: The outer layer provides light transmission, insulation, and weather protection, using materials like glass, plastic films (PE, PVC, EVA), or polycarbonate panels (PC, PMMA), each with varying properties.

- Foundation: Secures the greenhouse, preventing sinking or shifting, ranging from simple concrete piers to reinforced concrete structures depending on size and type.

- Doors, Windows & Ventilation: Doors allow access for personnel and materials, while ventilation systems (natural or forced) regulate temperature, humidity, and air circulation.

- Environmental Control Systems: Advanced systems precisely regulate temperature, humidity, light, CO2 levels, etc., including heating, cooling, shading, and irrigation systems.

- Heat Retention: Effectively traps heat, maintaining internal temperatures higher than the external environment, promoting crop growth.

- Light Transmission: Ensures adequate sunlight for photosynthesis through the cladding material.

- Controllability & Protection: Allows precise control of environmental factors, protecting crops from harsh weather (frost, rain, hail, wind) and pests.

- Season Extension & Increased Productivity: Breaks seasonal limitations for year-round growing, extending growing seasons, and optimizing conditions to boost crop yield and quality.

Chapter 4

Advantages and disadvantages of using greenhouses

Advantages

- Extended Growing Season: Crops can be cultivated year-round regardless of external climate conditions.

- Increased Yield and Quality: Controlled environments (temperature, humidity, CO₂) maximize plant growth efficiency.

- Pest and Disease Control: Physical barriers reduce pest invasions and minimize pesticide use.

- Resource Efficiency: Water-saving technologies (e.g., drip irrigation) reduce waste.

- Climate Resilience: Protects crops from extreme weather (storms, droughts, frost).

- Diverse Crop Cultivation: Enables growing non-native or tropical plants in unsuitable regions.

Disadvantages

- Ongoing Energy Consumption: Heating, cooling, and lighting often rely on fossil fuels, increasing carbon footprint.

- Technical Expertise Required:Managing sensors, irrigation systems, and climate control demands skilled labor.

- Risk of Monoculture Failures: Large-scale single-crop greenhouses face vulnerability to diseases or market fluctuations.

- Limited Scalability: Space constraints may require vertical farming integration for expansion.

- Potential Pollution from Waste:Accumulated chemical fertilizers or plastics (e.g., mulch films) can harm ecosystems.

Chapter 5

Why are some greenhouse structures more expensive?

Advantages

- Extended Growing Season: Crops can be cultivated year-round regardless of external climate conditions.

- Increased Yield and Quality: Controlled environments (temperature, humidity, CO₂) maximize plant growth efficiency.

- Pest and Disease Control: Physical barriers reduce pest invasions and minimize pesticide use.

- Resource Efficiency: Water-saving technologies (e.g., drip irrigation) reduce waste.

- Climate Resilience: Protects crops from extreme weather (storms, droughts, frost).

- Diverse Crop Cultivation: Enables growing non-native or tropical plants in unsuitable regions.

Disadvantages

- Ongoing Energy Consumption: Heating, cooling, and lighting often rely on fossil fuels, increasing carbon footprint.

- Technical Expertise Required:Managing sensors, irrigation systems, and climate control demands skilled labor.

- Risk of Monoculture Failures: Large-scale single-crop greenhouses face vulnerability to diseases or market fluctuations.

- Limited Scalability: Space constraints may require vertical farming integration for expansion.

- Potential Pollution from Waste:Accumulated chemical fertilizers or plastics (e.g., mulch films) can harm ecosystems.

Chapter 6

Physical properties of common materials in greenhouses

Greenhouse materials are selected based on their physical properties to ensure durability, light transmission, and thermal efficiency. Below is a side-by-side comparison of common materials used in greenhouse construction:

| Material | Glass | Polycarbonate | Polyethylene (PE) Film |

|---|---|---|---|

| Density (g/cm³) | 2.5–2.6 (varies by type, e.g., float glass) | 1.2–1.3 (depending on thickness and structure) | 0.9–0.96 (lightweight, flexible plastic) |

| Melting Point (°C) | ~1,400–1,600 (very high, depending on composition) | ~140–150 (thermoplastic, lower than glass) | ~110–130 (low melting point, prone to heat damage) |

| Light Transmission (%) | 85–90% (excellent for photosynthesis, minimal diffusion) | 80–90% (high, with some diffusion to reduce shading) | 75–85% (good, but may degrade over time with UV exposure) |

| Thermal Conductivity (W/m·K) | 0.8–1.0 (poor insulator, requires double-glazing for efficiency) | 0.2–0.3 (better insulation than glass, especially multi-walled) | 0.3–0.5 (moderate, but less insulating than polycarbonate) |

| Specific Heat Capacity (J/g·K) | 0.84 (requires significant energy to heat or cool) | 1.2–1.3 (higher, easier to manage temperature changes) | 1.8–2.0 (higher, but thin film limits overall impact) |

| Durability | Highly durable, resistant to weathering but brittle and prone to shattering under impact. | Very durable, impact-resistant, and flexible, lasting 10–20 years with UV protection. | Less durable, susceptible to tearing, UV degradation, and typically lasts 1–5 years. |

| Applications | Used in permanent, high-end greenhouses for optimal light and durability in botanical gardens and commercial setups. | Common in commercial and residential greenhouses for insulation and strength, especially in cold climates. | Ideal for temporary or seasonal greenhouses, low-cost tunnels, and hoop houses for vegetables and flowers. |

The choice of material depends on factors such as budget, climate, crop requirements, and desired longevity, ensuring optimal performance and efficiency in greenhouse operations.

Chapter 7

Do greenhouse structures rust or corrode?

Generally speaking, at CFGET, we prioritize the use of hot-dip galvanized steel for greenhouse structures. The environmental conditions in different regions, such as high-temperature and high-humidity areas or extremely arid regions, require different specifications for the galvanized coating. Therefore, we select the appropriate galvanizing index based on local climate characteristics.

Typically, we use a galvanizing index between 70 and 150 to ensure that the structural frame material can resist rust for approximately 20 years. In special cases, we can customize the rust-resistant lifespan, which can extend up to 30 years. However, it is important to note that in environments with chemical gas corrosion, the service life of the galvanized coating will be shortened accordingly.

Zinc Coating Thickness Reference (ISO 1461, ASTM A123, EN 10346):

For different application environments, the thickness of the hot-dip galvanized coating is usually set according to specific corrosion conditions. The standard range of zinc coating thickness is generally between 50 μm (microns) and 200 μm. The specific thickness is chosen based on the customer’s requirements and the intended service life.

* General use: 60-80 μm

* Harsh environments or higher corrosion resistance: 100-150 μm

* Extreme environments (e.g., chemical plants): Above 200 μm

Common International Units:

* Micrometers (μm): Usually used to describe the thickness of the galvanized coating. 1 μm = 0.001 millimeters.

* Inches (in) or Mils: In some countries, particularly the United States, the zinc coating thickness may also be measured in mils. 1 mil = 0.001 inches.

Chapter 8

Greenhouse Material Manufacturing Process

The manufacturing process of greenhouse materials involves several important steps to ensure durability and high quality. Below is a step-by-step guide to the process:

| Step | Description |

|---|---|

| 1. Raw Material Selection | The selection of appropriate raw materials is critical. Materials such as glass, polycarbonate, and polyethylene are chosen based on their light transmittance and durability to withstand harsh weather conditions. |

| 2. Material Processing | The selected raw materials are processed through various methods like cutting, shaping, and molding to match the specific design of the greenhouse. This ensures that they fit properly within the structure. |

| 3. UV Protection Treatment | To prevent degradation from sunlight exposure, materials like polycarbonate and polyethylene are treated with UV-resistant coatings or additives. This extends the lifespan of the materials. |

| 4. Coating and Insulation | Polycarbonate sheets and other materials are coated with additional layers to enhance thermal insulation. This helps in maintaining a stable internal temperature inside the greenhouse, reducing energy costs. |

| 5. Cutting and Shaping | The materials are precisely cut into required shapes and sizes, such as panels or sheets, to fit the structural design of the greenhouse. |

| 6. Structural Reinforcement | To ensure stability and withstand external factors like wind and snow, some materials are reinforced with steel or aluminum frames, especially in larger greenhouses. |

| 7. Assembly and Installation | The processed materials are assembled into the greenhouse framework, with proper sealing and connections to ensure thermal efficiency and structural integrity. |

| 8. Quality Control and Inspection | Once assembled, the greenhouse materials undergo strict quality control checks. This includes inspecting UV resistance, light transmittance, and overall structural integrity. |

| 9. Final Packaging and Shipping | After passing inspections, the greenhouse materials are carefully packaged to prevent damage during shipping. They are shipped as components or pre-assembled sections, depending on the greenhouse size. |

| 10. Final Setup and Maintenance | Upon arrival, the greenhouse is set up and installed. Regular maintenance is required to ensure the materials maintain their efficiency and durability over time. |

Chapter 9

Common types of greenhouses and their applications

Greenhouses come in various types, each designed for specific purposes and environmental conditions. Below is a side-by-side comparison to help delineate their differences:

| Type of Greenhouse | Lean-to Greenhouse | Freestanding Greenhouse | Hoop House (Polytunnel) |

|---|---|---|---|

| Structure | Attached to an existing building (e.g., a house or wall), with one sloped side for support. | Standalone structure with a full frame, typically rectangular or gabled, not attached to any building. | Curved, tunnel-like structure made of metal hoops covered with plastic film. |

| Size | Small to medium, limited by the supporting structure’s size, often 6–12 feet wide. | Can vary from small (8x8 feet) to large commercial sizes (100+ feet long). | Typically large and elongated, ranging from 20–100+ feet in length, narrow width. |

| Material | Usually glass or polycarbonate panels, with a sturdy frame (wood or metal). | Glass, polycarbonate, or acrylic panels, supported by aluminum or steel frames. | Polyethylene film or similar plastic, with galvanized steel or PVC hoops. |

| Cost | Moderately priced, lower than freestanding due to shared wall and simpler construction. | Generally more expensive due to full frame and larger materials needed. | Low cost, ideal for budget-conscious or temporary setups. |

| Climate Control | Limited control, relies on the attached building for some heat but can be less ventilated. | Excellent control with vents, fans, and heating systems for year-round use. | Basic control, often unheated, but can use passive solar heating and ventilation. |

| Applications | Small-scale gardening, hobbyists, or urban settings with limited space. | Commercial farming, research, or large-scale plant production year-round. | Seasonal vegetable or flower production, cost-effective for temporary crops. |

| Durability | Moderate, depends on frame and covering; can last 10–20 years with maintenance. | Highly durable, can last 20+ years with proper care and materials. | Less durable, typically lasts 1–5 years, depending on film quality and weather. |

The choice of greenhouse type depends on factors such as budget, space, climate, and the specific needs of the plants being grown, ensuring optimal growth conditions and efficiency.

Chapter 10

What are the commercial greenhouse products?

- Greenhouse Structures: These are the buildings themselves. They come in different styles like gutter-connected, freestanding, or high tunnels. Materials can be glass, polycarbonate, or plastic film. They protect plants from weather and pests.

- Covering Materials: These cover the greenhouse. Options include glass for durability, polycarbonate for insulation, or polyethylene film for affordability. They control light and temperature.

- Heating Systems: Heaters keep the greenhouse warm in cold weather. Common types use gas, propane, or electricity. Some systems also use hot water pipes.

- Cooling and Ventilation: Fans, vents, and cooling pads manage heat and air flow. This keeps plants healthy in hot climates.

- Lighting: Grow lights, like LED or fluorescent, help plants grow when sunlight is low, especially in winter or cloudy areas.

- Irrigation Systems: These deliver water to plants. Drip irrigation or sprinklers are popular. Some include hydroponics, where plants grow in water with nutrients.

- Benches and Trays: These hold plants off the ground. They save space and make work easier. Trays can be used for seedlings or hydroponics.

- Shade and Blackout Systems: Shade cloth reduces sunlight, while blackout curtains control light for plants that need specific day lengths.

- Environmental Controls: Sensors and automation systems monitor temperature, humidity, and CO2. They adjust conditions for the best growth.

- Accessories: This includes smaller items like pots, seed trays, fertilizers, and pest control products.

Chapter 11

Standards and specifications for greenhouse construction

《AGRICULTURAL GREENHOUSE STRUCTURAL LOAD SPECIFICATIONS》 GB/T 51183-2016;

《DESIGN OF VENTILATION IN GREENHOUSE》GB/T18621-2002;

《LOAD COMBINATION FOR GREENHOUSE STRUCTURAL》GB/T18622-2002;;

《NORMALIZING DESIGN AND INSTALLATION OF GREENHOUSE INSECT NET 》GB/19791-2005;

《GREENHOUSE COOLING SYSTEM》JB/T10294-2001;

《GREENHOUSE VENTILATION DESIGN SPECIFICATIONS》NY/T 1451-2007

Chapter 12

How to ensure the quality of greenhouse materials and structures?

To ensure the quality of greenhouse materials and structures, follow these steps:

- Choose Reliable Suppliers: Work with trusted suppliers who provide high-quality materials like steel, aluminum, or polyethylene film. Check their certifications or reputation.

- Test Material Durability: Use materials that resist weather, rust, and UV damage. For example, galvanized steel lasts longer than untreated metal, and UV-treated plastic film stays strong under sunlight.

- Check Structural Design: Make sure the greenhouse frame can handle wind, snow, or rain in your area. A strong design with proper joints and supports is key.

- Inspect During Production: Look at every part—frames, coverings, and fittings—before assembly. Check for defects like cracks, weak spots, or uneven cuts.

- Follow Standards: Use industry guidelines, like China’s greenhouse standards (if available), or international ones. This ensures materials and construction meet basic quality levels.

- Install Properly: Even good materials fail if installed badly. Train workers to assemble the greenhouse correctly, with tight seals and stable anchoring.

- Test After Building: After setup, check the structure under real conditions—wind, rain, or weight. Fix any weak points you find.

Chapter 13

Applications of greenhouses in different industries

Greenhouses have many uses across different industries. Here are some key applications:

- Agriculture:

Grow fruits, vegetables, and herbs year-round, even in cold or dry climates. Examples include tomatoes, cucumbers, and strawberries.

Protect crops from pests, rain, or extreme weather. - Floriculture:

Produce flowers like roses, lilies, or orchids for sale. Greenhouses control light and temperature for perfect blooms. - Horticulture:

Raise seedlings or young plants before moving them outside. This is common for trees, shrubs, or garden plants. - Research and Education:

Universities and labs use greenhouses to study plants, test new growing methods, or develop stronger crops. - Aquaculture:

Combine fish farming with plant growing (aquaponics). Plants use fish waste as fertilizer, and water stays clean. - Medicinal Plants:

Grow herbs or plants for medicine, like ginseng or aloe vera, in controlled conditions for high quality. - Seed Production:

Create seeds for crops or flowers. Greenhouses keep conditions steady to ensure seeds grow well. - Food Security:

In harsh climates (deserts or snowy areas), greenhouses provide fresh food locally, reducing imports.

Chapter 14

How to find reliable greenhouse suppliers?

Finding reliable greenhouse suppliers is crucial for ensuring quality products and long-term success in greenhouse operations. Below is a side-by-side comparison of methods to identify and evaluate trustworthy suppliers:

| Method | Online Research | Industry Associations | Trade Shows and Exhibitions |

|---|---|---|---|

| Description | Search for suppliers on websites, forums, and marketplaces like Google, agricultural directories, or e-commerce platforms specializing in greenhouse equipment. | Join or research associations like the American Horticultural Society or International Greenhouse Association for vetted supplier lists and recommendations. | Attend horticultural, agricultural, or greenhouse trade shows to meet suppliers in person, see products, and network with industry professionals. |

| Reliability Check | Review customer ratings, testimonials, and case studies; check for certifications (ISO, organic standards) and years in business. | Associations often verify members’ credibility, offering trusted contacts with proven track records in the industry. | Evaluate suppliers based on product demonstrations, reputation at the event, and direct feedback from other attendees or buyers. |

| Cost | Low to moderate; free online searches, but paid directories or consultations may apply. | Low to moderate; membership fees may be required, but resources are often free or discounted for members. | Moderate to high; travel and registration fees, but provides direct access to multiple suppliers. |

| Time Investment | Moderate; requires thorough research, comparisons, and follow-ups via email or calls. | Low to moderate; quick access to lists, but verifying suppliers may take additional time. | High; requires travel and planning, but offers immediate, hands-on evaluation. |

| Applications | Ideal for remote or budget-conscious buyers seeking a wide range of options from global suppliers. | Best for professionals looking for industry-endorsed, reputable suppliers with specialized knowledge. | Suitable for large-scale buyers or businesses wanting to build relationships and explore innovations in person. |

| Additional Tips | Verify supplier locations, shipping policies, and warranty terms; avoid overly cheap options without reviews. | Attend association webinars or events for deeper insights and direct supplier connections. | Prepare a list of questions about product durability, customization, and after-sales support before attending. |

The choice of method depends on your budget, time, and specific needs, such as local vs. international suppliers, product type, and long-term partnership goals, ensuring you find a reliable partner for your greenhouse project.

Chapter 15

Future trends in greenhouse technology

The greenhouse industry is evolving rapidly with advancements in technology, sustainability, and efficiency. Below is a side-by-side comparison of key future trends and their potential impacts:

| Trend | Smart Greenhouses (IoT Integration) | Sustainable Materials | Vertical Farming Integration |

|---|---|---|---|

| Description | Greenhouses equipped with Internet of Things (IoT) sensors, automation, and AI for real-time monitoring of climate, water, and plant health. | Use of eco-friendly, recyclable, or biodegradable materials like advanced polymers, bio-based plastics, and energy-efficient glass. | Combining traditional greenhouse structures with vertical farming systems to maximize space and yield in urban or limited-area settings. |

| Key Benefits | Improved efficiency, reduced labor, precise control of environmental factors, and data-driven decision-making for crop optimization. | Lower environmental impact, reduced carbon footprint, and compliance with green building standards. | Increased crop production per square foot, ideal for urban agriculture, and reduced transportation costs for fresh produce. |

| Cost | High initial investment for sensors, software, and automation systems, but long-term savings on labor and resources. | Moderate to high cost initially, but potential cost savings over time due to durability and reduced energy use. | High setup cost for structural modifications and LED lighting, but scalable for commercial profitability. |

| Technological Requirements | Requires IoT devices, cloud platforms, and possibly AI algorithms; needs reliable internet connectivity and technical expertise. | Development of new materials and testing for UV resistance, durability, and thermal properties; minimal tech beyond standard greenhouse systems. | Requires advanced lighting (e.g., LEDs), hydroponics/aeroponics systems, and structural engineering for multi-level designs. |

| Applications | Commercial farms, research facilities, and large-scale operations aiming for precision agriculture and year-round production. | Suitable for all greenhouse types, especially eco-conscious businesses and urban farms focused on sustainability. | Ideal for urban environments, high-value crops (e.g., herbs, microgreens), and regions with limited arable land. |

| Challenges | High upfront costs, potential cybersecurity risks, and need for skilled technicians to maintain systems. | Limited availability of materials, higher initial costs, and ensuring performance in diverse climates. | Complex installation, energy demands for lighting, and space constraints in retrofitting existing greenhouses. |

The adoption of these trends will depend on factors such as budget, location, crop type, and environmental goals, driving the future of greenhouse technology toward greater efficiency, sustainability, and productivity.

Chapter 16

How to improve crop yield and quality through greenhouse cultivation?

Greenhouse cultivation offers controlled environments to optimize crop growth, yield, and quality. Below is a side-by-side comparison of key strategies and their benefits:

| Strategy | Climate Control | Advanced Irrigation | Nutrient Management |

|---|---|---|---|

| Description | Use of heating, cooling, ventilation, and shading systems to maintain optimal temperature, humidity, and light levels. | Implementation of drip irrigation, hydroponics, or aeroponics to deliver precise amounts of water and reduce waste. | Application of balanced fertilizers, soil testing, and soilless growing media to ensure plants receive essential nutrients. |

| Key Benefits | Consistent growth conditions year-round, reducing stress on plants and boosting yield by 20–50% for crops like tomatoes and peppers. | Improves water efficiency by up to 90%, enhances root health, and increases yield by ensuring uniform hydration. | Optimizes plant health, increases fruit size and quality, and reduces nutrient deficiencies, potentially raising yield by 15–30%. |

| Cost | Moderate to high; depends on system complexity (e.g., automated vs. manual), but long-term savings on energy and labor. | Low to moderate; initial setup costs for systems, but significant water and labor savings over time. | Low to moderate; cost of fertilizers and testing, but efficient use minimizes waste and maximizes returns. |

| Technological Requirements | Requires sensors, thermostats, fans, and possibly IoT for automation; technical knowledge for maintenance. | Needs pumps, timers, and possibly nutrient delivery systems; minimal expertise for basic setups. | Requires soil or water testing kits, pH meters, and knowledge of nutrient schedules; advanced setups may use software. |

| Applications | Ideal for high-value crops (e.g., flowers, herbs, vegetables) in varying climates, ensuring consistent quality and yield. | Suitable for all greenhouse crops, especially water-sensitive plants like lettuce or strawberries. | Applicable to all crops, particularly nutrient-demanding plants like tomatoes, cucumbers, and peppers. |

| Challenges | High initial investment, energy costs, and need for regular maintenance and calibration of systems. | Potential clogging or system failures require monitoring; initial setup can be complex for large greenhouses. | Requires regular testing and adjustment; over-fertilization can harm plants or the environment if mismanaged. |

The effectiveness of these strategies depends on factors such as crop type, greenhouse design, budget, and local climate, ultimately leading to higher yields, better quality, and sustainable production.

Chapter 17

How can the energy efficiency of greenhouses be improved?

- Use of Insulation: Adding better insulation materials like double-glazed glass or thermal screens can help maintain a stable temperature inside the greenhouse, reducing the need for heating.

- Natural Ventilation: Design the greenhouse with openings or vents that allow fresh air to flow in and hot air to escape. This reduces the need for artificial cooling, especially in warm climates.

- Shading Systems: Use shade nets or adjustable shading systems to block excess sunlight during the hottest parts of the day. This helps to reduce the need for cooling systems and protects plants from heat stress.

- Energy-efficient Heating: Use energy-efficient heating systems, such as heat pumps or geothermal heating, to reduce energy use for maintaining temperature. These systems can take heat from the ground or air, making them more efficient than traditional heating methods.

- LED Lighting: Replace traditional lights with energy-efficient LED lights, which consume less power and produce less heat.

- Automated Climate Control: Use sensors and smart systems to automatically adjust the greenhouse environment. This can optimize temperature, humidity, and light levels based on real-time data, reducing unnecessary energy use.

Chapter 18

What is the approximate cost of building a greenhouse?

- Small Greenhouse :Basic structure: $500 – $3,000

Materials: Polycarbonate panels or plastic film

For personal or small-scale use, this is the most affordable option. - Medium Greenhouse :Basic structure: $3,000 – $10,000

Materials: Polycarbonate or polyethylene plastic, metal or wood frame

Suitable for commercial use or hobbyists growing a variety of plants. - Large Greenhouse :Basic structure: $10,000 – $50,000+

Materials: Polycarbonate panels, steel or aluminum frame

This is a larger commercial greenhouse with space for many plants and advanced systems (e.g., heating, cooling, irrigation). - High-tech Greenhouse:Cost: $50,000 – $200,000+

Features: Automated climate control, solar panels, LED lighting, advanced irrigation, and energy-efficient systems

Used for large-scale, professional farming, often incorporating renewable energy and modern technology.

Other factors that can affect costs include:

- Location: Transportation costs for materials and labor.

- Foundation: Some greenhouses may need reinforced foundations, especially in areas with extreme weather.

- Additional features: Shading systems, ventilation, heating, cooling, or automated systems can increase the cost.

- It’s important to plan for both the initial cost and ongoing maintenance.

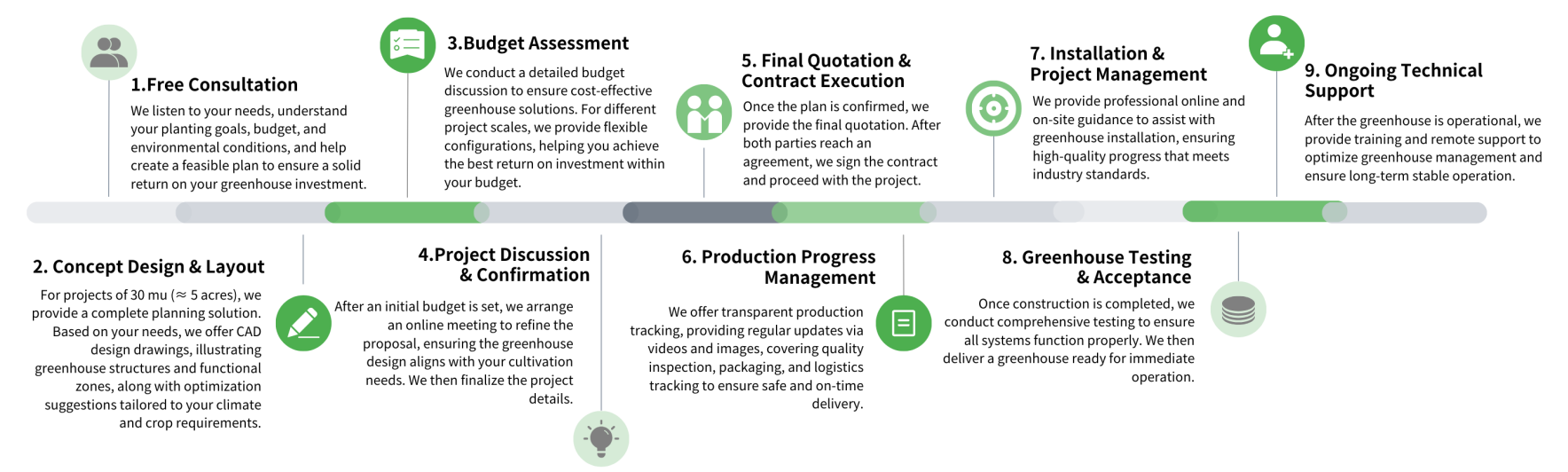

Our service process

10 Key Questions for Greenhouse Agriculture Investment

01.What Are the Costs and Payback Time for Greenhouse Farming?

1) Investment Costs

- Construction Costs: Land, greenhouse structure (frame, covering materials), supporting systems (irrigation, heating, lighting), and infrastructure (roads, water, electricity).

- Operating Costs: Labor, utilities, seedlings, fertilizers, pest control, packaging, transportation, and sales expenses.

- Maintenance Costs: Greenhouse structure repairs, replacement of covering materials, and equipment maintenance (ventilation, irrigation).

2) Payback Period Based on market research and technical conditions, typical cases include:

- Short-term (0.6 – 1.5 years): Lettuce, spinach, strawberries, mushrooms. Low investment, simple management, suitable for contract farming.

- Mid-term (1.5 – 3 years): Tomatoes, peppers, cucumbers, blueberries. Continuous harvesting, high yield, requires precise management.

- Long-term (3 – 5 years): High-end flowers, medicinal herbs, fruit trees. Branding required, high market value.

3) Factors Affecting Payback Speed

- Location: Logistics costs and market accessibility.

- Crop Selection: Market demand, sales channels, and profitability.

- Technology: Precision control to reduce losses.

- Sales Strategy: Contract farming and brand marketing.

Recommendation: Beginners should start with low-cost plastic greenhouses or mid-level multi-span greenhouses, focus on stable market crops such as leafy greens, tomatoes, and peppers, and use contract farming to reduce investment risks.

02.Which Type of Greenhouse Is Best for Investment?

Different greenhouses suit different investment levels and market needs:

- Plastic Greenhouse: Low cost, quick to build, ideal for seasonal crops like leafy greens and strawberries.

- Multi-span Greenhouse: Suitable for mid-scale commercial farming, good ventilation, ideal for crops like tomatoes and peppers.

- Glass Greenhouse: High investment, advanced smart management, best for high-value crops like blueberries and flowers.

- Smart Greenhouse: Best for long-term investment, highly automated, precise climate control, suitable for premium markets.

Recommendations:

- Small-scale/Beginner: Plastic greenhouse or multi-span film greenhouse.

- Mid-scale/Long-term operation: Multi-span glass greenhouse or smart greenhouse.

- High-end/Export market: Smart greenhouse or high-end glass greenhouse.

03. How to Choose High-Profit Crops?

1) Crop Categories

- Short-term High Profit: Leafy greens grow quickly and sell fast.

- Stable Market Demand: Tomatoes, peppers, cucumbers, and melons are suitable for large-scale sales.

- High-Value Crops: Blueberries, strawberries, and cherry tomatoes have strong market demand but require advanced management.

- Specialty Crops: Medicinal plants and flowers (roses, orchids) target niche markets.

2) Selection Criteria

- Market Demand: Is there a stable order or buyer?

- Growth Cycle: Short-term profit vs. long-term investment.

- Maintenance Difficulty: Pest risks and technical requirements.

- Price Stability: Does the crop have strong and consistent pricing?

Conduct feasibility research based on local agricultural markets. Below is a summary of common crop choices from our customers for reference.

04.How to Reduce Operating Costs and Increase Profit in Greenhouse Farming?

Reducing costs is key to improving profitability. Using automation such as drip irrigation and smart monitoring can lower water, electricity, and labor expenses. Energy-saving solutions like solar power and rainwater collection help cut utility costs. Precision fertilization minimizes waste while improving crop quality. Additionally, adopting eco-friendly pest control reduces reliance on chemical pesticides, lowering input costs and enhancing sustainability.

To maximize profits, farmers can increase product value through organic certification and branding. Boosting yield with optimized growing methods, such as vertical farming, improves efficiency. Expanding sales channels, including e-commerce and contract farming, ensures a stable market and higher returns.

05. What Are the Potential Risks in Greenhouse Farming and How to Mitigate Them?

Greenhouse farming faces several risks that can impact profitability. Market price fluctuations may reduce expected revenue, while extreme weather events such as storms, heavy rainfall, or hail can damage structures and crops. Pest and disease outbreaks can significantly affect yield, and water or electricity supply disruptions may hinder essential greenhouse operations. These factors create uncertainties that require proactive management.

To minimize these risks, farmers can adopt long-term sales contracts to secure stable pricing and avoid market volatility. Investing in agriculture insurance provides financial protection against extreme weather and crop losses. Diversifying crops reduces reliance on a single product, spreading risk more effectively. Implementing smart monitoring systems allows for real-time tracking and early warnings, enabling quick responses to environmental changes and operational challenges.

06.What Are the Market Demand and Sales Channels for Greenhouse Farming?

Greenhouse-grown products have a wide market demand and multiple sales channels. Farmers can sell through wholesale markets, which offer large-scale distribution but lower prices. Supermarkets and restaurants provide stable demand but require consistent quality and supply. E-commerce and community group buying platforms allow direct-to-consumer sales with higher margins. Additionally, food processing companies purchase raw agricultural products for further production, and the export market offers opportunities for premium produce but requires compliance with regulations.

To establish a strong market presence, farmers can use brand marketing to enhance product value and attract premium buyers. Contract farming with businesses ensures predictable sales and stable pricing. Engaging in B2B partnerships with restaurants and food processing companies secures long-term demand, reducing reliance on fluctuating retail markets.

07.What Are the Profit Models for Greenhouse Farming?

Greenhouse farming offers both traditional and innovative profit models. The traditional approach includes selling produce through wholesale markets, which provide bulk sales but lower margins. Direct supply to supermarkets and restaurants ensures stable demand and pricing. Retail sales at farmers’ markets allow for higher prices but require more effort in distribution and marketing.

Innovative models can further increase profitability. Pick-your-own farms and agritourism attract consumers willing to pay for an experience. Contract farming secures guaranteed sales with businesses. Organic certification adds value by appealing to premium markets. Processing agricultural products, such as dried fruits or juices, extends shelf life and enhances marketability, offering higher returns compared to raw produce.

08. How to Apply for Government Subsidies or Agricultural Investment Support?

Government support for greenhouse farming comes in different forms. Facility subsidies cover greenhouse construction and water-saving irrigation. Low-interest agricultural loans provide financial assistance for farming projects. Technology grants support investments in smart greenhouses and sustainable agriculture.

The application process involves checking eligibility, preparing necessary documents, submitting the application, and undergoing site inspection before funds are disbursed. Farmers should consult local agricultural departments for specific requirements and timelines.

09.Is Investing in a Smart Greenhouse Worth It?

Smart greenhouses use advanced technologies such as automated irrigation, environmental monitoring, AI-driven crop management, and remote control systems to improve efficiency.

Although initial investment costs are high, smart greenhouses offer long-term benefits through optimized resource use, reduced labor dependency, and higher yields. They are ideal for large-scale farming operations where automation can significantly enhance profitability.

10.What Are the Key Factors in Greenhouse Construction?

Location selection is critical, considering factors like climate (water supply, electricity, sunlight), transportation (proximity to markets), and land policies to ensure compliance with agricultural regulations.

The greenhouse structure should be designed for wind and snow resistance, proper ventilation and insulation, and scalability for future expansion. Choosing the right materials and layout ensures long-term durability and cost efficiency.

How to Choose the Right Greenhouse Type for Your Growing Plan?

Choosing the right greenhouse affects yield, cost, and efficiency. Options range from plastic tunnels to multi-span, glass, and smart greenhouses, each suited for different climates, crops, and business goals.

Suitable for windy, snowy, or humid areas, ensuring durability.

The cost of building a greenhouse depends on the materials and design:

- Glass Greenhouses: These are the most expensive because they use high-quality glass and need a strong framework. They are ideal for high-end farming and long-term investment.

- Plastic Film Greenhouses: These are the most affordable. The plastic film (like polyethylene) is cheap, and installation is easy. It’s a good choice for small to medium-sized farms.

- Polycarbonate Greenhouses: These are moderately priced. Polycarbonate panels are good for insulation and can last longer. They are ideal for temperate or cold climates.

- Fiberglass Greenhouses: These are less common but offer strong durability and can withstand bad weather. Their cost is similar to glass greenhouses.

In general, plastic film greenhouses are the cheapest. Glass and polycarbonate greenhouses are better for long-term investments.

Glass Greenhouses:

- Advantages: High light transmission, durable, can withstand strong winds and heavy snow, ideal for high-value crops.

- Disadvantages: Expensive, installation takes longer, higher maintenance costs.

Plastic Film Greenhouses:

- Advantages: Low cost, easy installation, good insulation, ideal for small-scale or short-term use.

- Disadvantages: Shorter lifespan, needs regular replacement, lower UV protection and light transmission compared to glass.

Polycarbonate Greenhouses:

- Advantages: Good insulation, UV protection, long-lasting, suitable for many climates.

- Disadvantages: More expensive than plastic film, but cheaper than glass.

Fiberglass Greenhouses:

- Advantages: Strong and durable, can handle harsh weather.

- Disadvantages: Lower light transmission compared to glass, expensive, requires some maintenance.

When choosing the best greenhouse, consider:

- Budget: If you have a small budget, plastic film greenhouses are the most cost-effective. For a higher budget, glass or polycarbonate greenhouses are better options.

- Climate: In cold climates, polycarbonate or glass greenhouses are best because they provide good insulation. In warmer or tropical climates, plastic film greenhouses are often enough.

- Crop needs: High-value crops (like tropical plants or flowers) might need a glass or polycarbonate greenhouse because they offer better light and temperature control.

- Lifespan: For long-term use, consider glass or polycarbonate. If you need a temporary or small-scale solution, plastic film greenhouses are good.

Greenhouses come in several structure types:

- Arch Roof (Dome-shaped): The most common design. It’s easy to build, handles wind well, and helps snow slide off. It’s a good choice for most climates.

- Gable Roof (Pointed Roof): This type is better for areas with heavy snow or wind. It’s stronger than an arch roof but doesn’t let as much light in.

- Flat Roof: Less common, used for larger, commercial greenhouses. It’s suitable for some temperate climates but doesn’t handle snow or wind as well.

The arch and gable roof designs are most common for typical agricultural greenhouses. Flat roofs are used for larger-scale operations.

Plastic Film Greenhouses: They are usually double-layered or multi-layered, which provides good insulation. In cold climates, they help maintain a warm inside temperature.

Glass Greenhouses: While glass allows a lot of light, it doesn’t provide as much insulation as plastic film. Even double-glazed glass doesn’t keep the heat as well as plastic film.

Overall, if you need better insulation for colder climates, plastic film greenhouses might be the better choice. Glass greenhouses are better in warmer areas where light is more important.

Temperate Climates: For temperate regions, polycarbonate or glass greenhouses are the best. They provide good light and insulation and can handle seasonal temperature changes.

Cold Climates: In cold regions, choose a double-layered plastic film greenhouse or a polycarbonate greenhouse. Both provide excellent insulation and can keep the heat in during the winter.

In colder climates, ensure that the greenhouse has good insulation and a strong framework to survive strong winds and snow.

Why choose CFGET?

With 28 years of expertise in greenhouse design and manufacturing, CFGET is committed to providing high-quality, customized solutions for growers worldwide. We integrate advanced technology, ensuring efficient climate control and energy savings. Our global experience allows us to adapt to various agricultural needs, delivering durable, high-performance structures. From initial planning to after-sales support, we prioritize reliability, innovation, and customer success.

Send us a message

*This site is protected by reCAPTCHA and is subject to the Google Privacy Policy and Terms of Service.

Get in touch with us

Whether it’s greenhouse design, selection of planting systems, or customized needs, our expert team will provide you with efficient and cost-effective solutions.

No.108, Hegang Road, South AreaChengdu Modern Industrial Park, Pidu DistChengdu, Sichuan, China