Traditional soil farming limits your profits. Water costs rise. Labor demands increase. NFT hydroponics eliminates these barriers and accelerates your path to consistent, year-round revenue.

NFT (Nutrient Film Technique) hydroponics delivers nutrient solutions through thin films flowing past plant roots. This membrane technology suits rapid-turnover leafy vegetables with high resource utilization efficiency. NFT systems reduce water usage by 90% while increasing yields 3-5x compared to soil farming.

I discovered NFT’s power during a project crisis in Thailand. A lettuce grower faced flooding that destroyed his soil crops repeatedly. We installed an NFT system in 30 days. His first harvest came 25% faster than soil crops. Water usage dropped to almost nothing. Profits increased by 200% within the first year.

The Science of the Nutrient Film: How Constant Flow Supercharges Growth?

Plant roots need three things: nutrients, water, and oxygen. Soil provides these inconsistently. NFT delivers all three in perfect balance through continuous nutrient flow.

The nutrient film technique creates a thin layer of nutrient solution flowing continuously past plant roots. This constant flow provides immediate nutrient access while maintaining optimal oxygen levels. Plants grow 40-60% faster than soil cultivation due to perfect nutrient availability and root zone oxygenation.

The science behind NFT reveals why this method works so effectively. Traditional soil creates barriers between roots and nutrients. Plants expend energy growing extensive root systems to find food and water. NFT eliminates this search process by delivering nutrients directly to roots.

The thin film design maintains the perfect balance between nutrition and oxygenation. Nutrient solution flows along channel bottoms while air spaces above provide oxygen to root systems. This combination prevents root rot while ensuring constant nutrient uptake. Plants focus energy on leaf production instead of root development.

I measured root development in parallel NFT and soil lettuce crops. Soil plants developed root systems 3-4 times larger to gather the same nutrients that NFT plants received passively. The NFT plants directed this saved energy into leaf production, resulting in 45% larger harvests.

Flow rate control determines system success. Too fast, and nutrients pass by roots without absorption. Too slow, and stagnation causes root problems. The optimal flow rate varies by crop type and growth stage but typically ranges from 1-3 liters per minute for standard channels.

Nutrient concentration remains consistent throughout the system due to continuous circulation. Traditional irrigation delivers nutrients in pulses, creating feast-or-famine cycles that stress plants. NFT provides steady nutrition that matches plant uptake rates throughout the day.

The slope angle of NFT channels affects flow characteristics significantly. Gradients between 1:30 and 1:40 provide optimal flow rates for most leafy crops. Steeper slopes create turbulent flow that damages delicate roots. Flatter slopes cause pooling and stagnation problems.

| Growth Factor | Soil Farming | NFT Hydroponics | Improvement |

|---|---|---|---|

| Nutrient Availability | Variable | Constant | +60% uptake |

| Root Oxygenation | Limited | Optimal | +40% growth |

| Water Efficiency | 100% baseline | 10% of soil | 90% savings |

| Growth Speed | 100% baseline | 140-160% | 40-60% faster |

Temperature control of the nutrient solution influences plant performance dramatically. Cool solutions (65-72°F) carry more dissolved oxygen and prevent root disease. Warm solutions above 75°F promote bacterial growth and reduce oxygen content. Chilling systems maintain optimal temperatures in hot climates.

The continuous flow eliminates salt buildup that plagues other hydroponic methods. Excess salts wash away before concentrating around roots. This self-cleaning action maintains healthy root zones without frequent system flushes. Plants experience consistent growing conditions throughout their lifecycle.

High Density, Low Water Use: The Unbeatable ROI of NFT Systems?

Space costs money. Water becomes expensive. Labor demands increase with traditional farming. NFT systems maximize production density while minimizing resource consumption and operational costs.

NFT systems achieve plant densities 4-6 times higher than soil farming while using 90% less water. This combination delivers ROI of 200-400% within the first year for leafy green operations. High-density production generates more revenue per square foot than any other growing method.

The mathematics of NFT profitability become clear when you calculate production per square foot. Traditional lettuce farming yields 8-12 heads per square meter per growing cycle. NFT systems routinely produce 32-48 heads in the same space through vertical stacking and tight spacing.

I analyzed financial data from a commercial NFT facility in California. Their 2,000 square foot greenhouse produces 15,000 lettuce heads monthly. The same production would require 8,000 square feet of field space. Land savings alone justified the system investment within 18 months.

Water efficiency creates additional cost advantages in drought-prone regions. NFT systems recirculate nutrient solutions continuously, losing water only through plant uptake and evaporation. A typical NFT operation uses 5-10 gallons per pound of lettuce produced compared to 50-80 gallons for field production.

The closed-loop design eliminates fertilizer runoff that wastes money and pollutes groundwater. Every nutrient molecule serves plant growth instead of washing away. Fertilizer costs drop by 60-80% compared to soil farming while achieving superior plant nutrition.

Labor efficiency multiplies with NFT design. Plants grow at convenient working heights, eliminating back-breaking field work. Harvesting proceeds faster due to uniform plant spacing and clean growing conditions. One worker can harvest 3-4 times more produce per hour than field operations.

Pest and disease pressure drops significantly in NFT systems. Soilborne pathogens cannot establish in sterile growing media. Clean growing conditions reduce insect infestations. Pesticide costs decrease while produce quality increases due to reduced chemical inputs.

| Economic Factor | Field Production | NFT Production | Advantage |

|---|---|---|---|

| Yield per sq ft | 2-3 lbs/year | 12-18 lbs/year | 4-6x higher |

| Water Usage | 50 gal/lb | 5 gal/lb | 90% reduction |

| Labor Hours | 100% baseline | 30% of field | 70% savings |

| Fertilizer Cost | 100% baseline | 25% of field | 75% reduction |

Climate control integration maximizes NFT profitability. Greenhouse environments extend growing seasons and protect crops from weather damage. Year-round production generates consistent revenue streams that field farming cannot match. Premium pricing for local, fresh produce increases profit margins.

The scalability of NFT systems accommodates business growth without proportional land acquisition. Vertical expansion doubles or triples production capacity within existing structures. Modular channel designs allow incremental capacity additions as market demand increases.

Quality premiums justify NFT investments in high-value markets. Restaurant buyers pay 20-50% premiums for consistent, clean, locally-grown leafy greens. NFT produce arrives at market within hours of harvest instead of days from distant fields. This freshness advantage commands premium pricing year-round.

Why NFT is the #1 Choice for Commercial Lettuce, Herb, & Kale Production?

Different crops need different growing methods. NFT matches perfectly with leafy greens’ biology and market demands. Commercial growers choose NFT because it maximizes profits for high-turnover crops.

NFT systems excel with leafy greens because these crops have shallow root systems, short growing cycles, and high water content. Lettuce, herbs, and kale achieve optimal growth in 25-35 days compared to 45-60 days in soil. Fast turnover and consistent quality make NFT the preferred commercial method.

Leafy greens possess biological characteristics that align perfectly with NFT advantages. Their fibrous root systems spread laterally instead of growing deep. This root structure maximizes contact with the flowing nutrient film. Deep-rooted crops like tomatoes cannot utilize NFT effectively due to their taproot growth patterns.

The rapid growth cycle of leafy greens multiplies NFT’s efficiency advantages. Lettuce completes its lifecycle in 4-5 weeks under NFT systems compared to 6-8 weeks in soil. This speed increase allows 10-12 crops annually instead of 6-8 traditional cycles. Revenue per square foot increases proportionally with cycle frequency.

I compared identical lettuce varieties in NFT and soil systems at our research facility. The NFT crops reached harvest size 18 days faster on average. This time advantage translated to two additional growing cycles annually, increasing total production by 33% from the same space.

Market demands for leafy greens favor NFT production methods. Restaurants and grocery stores require consistent size, color, and quality that field production cannot guarantee. Weather variations create supply disruptions and quality inconsistencies that frustrate buyers. NFT delivers uniform products year-round regardless of external conditions.

Herb production particularly benefits from NFT’s clean growing environment. Basil, cilantro, and parsley command premium prices when free from soil contamination and pest damage. The sterile growing conditions eliminate washing requirements that damage delicate herb leaves. Shelf life extends significantly due to reduced bacterial contamination.

Kale production in NFT systems produces tender leaves that appeal to fresh market consumers. Field-grown kale often develops tough, bitter leaves due to stress conditions. NFT kale maintains consistent moisture and nutrition levels that create sweet, tender leaves throughout the growing season.

| Crop Type | Soil Cycle Time | NFT Cycle Time | Annual Cycles | Yield Increase |

|---|---|---|---|---|

| Lettuce | 45-60 days | 25-35 days | 10-12 vs 6-8 | +50-100% |

| Basil | 60-75 days | 35-45 days | 8-10 vs 5-6 | +60-80% |

| Kale | 55-70 days | 30-40 days | 9-12 vs 5-7 | +70-140% |

| Spinach | 40-50 days | 20-28 days | 13-18 vs 7-9 | +85-200% |

The harvesting advantages of NFT systems reduce labor costs while improving product quality. Plants grow at uniform heights with clean root systems that separate easily from growing channels. Harvesting proceeds quickly without soil contamination or root damage. Workers can harvest entire crops in single passes instead of selective picking.

Post-harvest handling improves dramatically with NFT production. Clean roots eliminate washing steps that damage leaves and reduce shelf life. Uniform sizing simplifies packaging operations. Consistent quality reduces sorting and grading labor. These efficiency gains reduce processing costs by 30-40% compared to field crops.

Storage and transportation benefits extend NFT’s market advantages. Clean, uniform products pack efficiently and maintain quality during shipping. Reduced moisture loss and bacterial contamination extend shelf life significantly. Buyers prefer NFT products for their consistency and extended freshness periods.

The 4 Core Components of a Successful NFT Hydroponics Setup?

System success depends on proper component selection and integration. Four critical elements determine whether your NFT operation thrives or fails. Understanding each component prevents costly mistakes and ensures optimal performance.

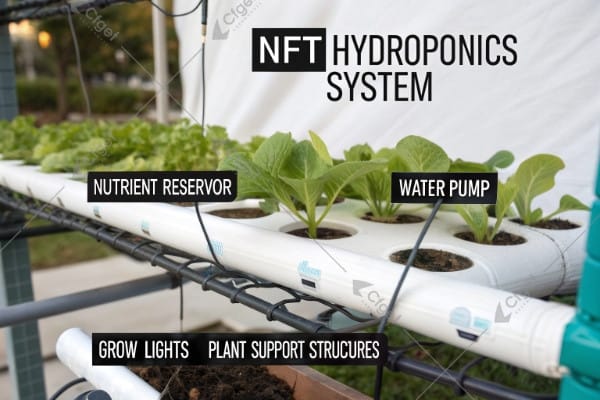

Successful NFT systems require four core components: properly sloped growing channels, reliable nutrient circulation pumps, balanced nutrient reservoirs, and effective environmental controls. Each component must function perfectly to maintain the delicate balance that makes NFT productive. Component failure can destroy entire crops within hours.

Growing channels form the foundation of every NFT system. Channel design affects water flow, root development, and plant spacing. Poor channel selection causes uneven growth, root problems, and reduced yields. Professional channels feature smooth surfaces, proper dimensions, and durable construction materials.

The channel slope requires precise calculation for optimal performance. I’ve seen systems fail because installers used incorrect gradients. Too steep, and solution flows too fast for nutrient uptake. Too flat, and stagnation causes root rot. The standard 1:30 to 1:40 slope works for most leafy crops but may need adjustment for specific varieties.

Channel width and depth determine plant capacity and root space. Standard channels accommodate 4-6 inch plant spacing for lettuce and herbs. Wider channels allow larger plants but reduce planting density. Depth must provide adequate flow volume without creating stagnant pools that harbor bacteria.

Circulation pumps maintain the continuous flow that makes NFT effective. Pump failure kills crops quickly as roots dry out within hours. Reliable pumps with backup systems prevent catastrophic losses. Flow rate calculations ensure adequate solution delivery without waste or root damage.

I learned about pump reliability the hard way during a weekend system failure. A single pump failure killed 2,000 lettuce plants because no backup existed. Now I specify dual pump systems with automatic switching for commercial installations. The extra cost prevents devastating crop losses.

Pump sizing requires careful calculation based on channel length, number of channels, and desired flow rates. Undersized pumps cannot maintain adequate flow to distant channels. Oversized pumps waste energy and may create excessive turbulence that damages roots. Professional sizing ensures optimal performance and energy efficiency.

| Component | Critical Specifications | Failure Consequences | Prevention Methods |

|---|---|---|---|

| Channels | 1:30-1:40 slope, smooth surface | Uneven growth, root rot | Professional design |

| Pumps | Adequate flow rate, reliability | Complete crop loss | Backup systems |

| Reservoir | Proper size, mixing | Nutrient imbalances | Monitoring systems |

| Environment | Temperature, humidity control | Stress, disease | Automated controls |

Nutrient reservoirs store and condition the solution that feeds your crops. Reservoir size must accommodate system volume plus daily plant uptake. Small reservoirs require frequent refilling and monitoring. Large reservoirs provide stability but waste nutrients during solution changes.

Solution mixing within reservoirs prevents stratification and ensures uniform nutrient distribution. Stagnant reservoirs develop concentration gradients that starve some plants while overfeeding others. Circulation pumps or mixing systems maintain homogeneous solutions throughout the reservoir volume.

Environmental controls coordinate with NFT systems to maintain optimal growing conditions. Temperature affects nutrient uptake rates and root health. Humidity influences transpiration and disease pressure. Automated systems adjust environmental parameters based on plant needs and system performance.

The integration between components determines overall system success. Pump timers coordinate with lighting schedules to match nutrient delivery with photosynthesis rates. Temperature sensors trigger cooling systems when solution temperatures rise. pH and EC monitors alert operators to nutrient imbalances before they damage crops.

Monitoring systems provide early warning of component problems. Flow sensors detect pump failures immediately. Temperature alarms prevent root damage from overheated solutions. Automated alerts allow rapid response to system problems before they become crop disasters.

Conclusion

NFT hydroponics delivers unmatched profitability for leafy green production through efficient resource utilization, rapid growth cycles, and premium product quality that commands higher market prices.