Choosing the wrong greenhouse manufacturer can cost you millions in lost crops and operational failures. Many cannabis growers struggle with facilities that weren’t designed specifically for this demanding crop.

The right cannabis greenhouse manufacturer combines agricultural expertise with cannabis-specific knowledge. Look for companies with documented experience in cannabis cultivation environments, ability to provide customized solutions for different growth stages, and comprehensive post-installation support.

I’ve been in the greenhouse manufacturing industry for over 28 years, and I’ve seen the cannabis cultivation sector evolve dramatically. When I first started designing specialized growing environments, very few manufacturers understood the unique needs of cannabis cultivation. Today, as the industry expands globally, selecting the right greenhouse partner has become both more important and more complex. Let me share what I’ve learned about making this critical decision.

Top 5 Questions to Ask Before Partnering with a Cannabis Greenhouse Supplier?

Many growers rush into partnerships without asking critical questions, leading to costly retrofits and production delays. The right questions upfront can save you from making a six-figure mistake.

Before signing with any cannabis greenhouse manufacturer, ask about their cannabis-specific experience, customization capabilities, available environmental controls, local compliance knowledge, and post-installation support services. These five areas will reveal whether a supplier truly understands cannabis cultivation needs.

When I visit potential clients, I often find they’ve already made costly mistakes with previous greenhouse partners who didn’t understand cannabis cultivation. One grower in California invested nearly $2 million in a greenhouse that couldn’t maintain proper light deprivation cycles – a basic requirement for cannabis production. Their entire crop schedule was compromised before they even started.

Experience in Cannabis-Specific Projects

The first question should always focus on direct experience with cannabis facilities. General greenhouse experience isn’t enough for this specialized crop. Ask for specific examples of cannabis projects they’ve completed, including size, location, and design specifications.

A reputable manufacturer will provide case studies or references from other cannabis operations. They should understand the regulatory differences between medical and recreational markets, as these often affect facility requirements. For example, our company completed a 25,000 sq ft medical cannabis facility in Thailand that required very different specifications than our 50,000 sq ft recreational facility in California.

Customization Capabilities

Cannabis cultivation requires different environments during various growth stages. Your manufacturer should offer solutions for propagation, vegetation, flowering, and post-harvest processes – not just a standard greenhouse structure.

Look for manufacturers who ask detailed questions about your cultivation goals, methods, and scale before proposing solutions. They should discuss options for light deprivation systems, supplemental lighting arrangements, and segregated growing zones. When we designed a multi-zone facility for a client in Michigan, we created separate environments for mother plants, clones, vegetation, and flowering – each with independent climate controls tailored to that specific growth phase.

Environmental Control Systems Integration

Cannabis thrives under precise environmental conditions. Ask potential manufacturers about their approach to temperature management, humidity control, and CO2 enrichment systems.

Beyond basic climate controls, discuss how their systems handle cannabis-specific challenges like preventing hermaphroditism from light leaks or managing vapor pressure deficit throughout different growth stages. The manufacturer should offer integrated solutions for airflow management and precise climate zones. Last year, we engineered a system for a client in Arizona that maintained consistent conditions despite outdoor temperatures ranging from 30°F to 115°F through sophisticated insulation and multiple redundant cooling systems.

Compliance Knowledge for Your Region

Cannabis regulations vary dramatically by location. Your greenhouse manufacturer should understand local compliance requirements for security, odor control, and production reporting.

Ask about their familiarity with your region’s specific requirements and how they address these in their designs. A knowledgeable manufacturer will discuss features like secure access points, surveillance system integration, and odor mitigation strategies that satisfy local regulations. When we built a facility in Oregon, we incorporated specialized carbon filtration systems specifically sized to meet the county’s strict odor control requirements.

After-Sale Support and Maintenance

The relationship with your greenhouse manufacturer shouldn’t end at installation. Cannabis cultivation facilities require ongoing support for optimal operation.

Inquire about training programs, technical support availability, and maintenance services. The best manufacturers offer comprehensive training for your staff, readily available technical support when issues arise, and preventative maintenance programs. When a critical environmental controller failed at our client’s facility in Colorado during peak flowering season, our technician was on-site within 8 hours to prevent what could have been a catastrophic crop loss.

Evaluating Greenhouse Manufacturers: Experience, Customization, and Support?

Many cannabis growers find themselves with structures that fail during critical growing periods. The difference between success and failure often lies in the manufacturer’s specific expertise and support capabilities.

Thoroughly evaluate potential greenhouse partners by checking their track record with cannabis-specific projects, their engineering capabilities for customized solutions, and their commitment to ongoing technical support. The best manufacturers demonstrate understanding of cannabis cultivation cycles and can provide solutions for each growth stage.

I remember visiting a large-scale operation that had invested over $4 million in greenhouse infrastructure from a manufacturer with no cannabis experience. Their light deprivation system leaked light during critical flowering periods, their humidity control was inadequate for dense cannabis canopies, and they had no way to create separate environmental zones for different growth stages. Essentially, they had purchased expensive vegetable greenhouses that were fundamentally unsuited for cannabis production.

When evaluating greenhouse manufacturers, look beyond the basic structure to assess their complete understanding of cannabis cultivation requirements. The most successful cannabis operations typically partner with manufacturers who bring specific knowledge about the plant’s needs throughout its lifecycle.

Track Record and Portfolio Analysis

Examine the company’s history with cannabis specifically. Many greenhouse manufacturers claim cannabis expertise but have minimal direct experience. Request detailed case studies of cannabis projects they’ve completed, including size, scope, and challenges overcome during implementation.

I recommend asking for virtual or in-person tours of their completed cannabis facilities. This allows you to see their work firsthand and speak with current operators about their experience. When evaluating manufacturers for our clients, we always request performance data from existing installations, particularly focusing on energy efficiency and crop yields. A manufacturer confident in their cannabis solutions will readily provide this information.

During my recent visit to a potential manufacturing partner, I noticed their "cannabis portfolio" consisted mostly of adapted vegetable greenhouse designs with minimal modifications for cannabis cultivation. This contrasted sharply with another manufacturer who showed us specialized designs with integrated light deprivation systems, vapor pressure deficit management tools, and cultivation-specific ventilation solutions developed through years of cannabis-focused projects.

Engineering Capabilities and Design Process

Cannabis cultivation requires precise engineering for optimal results. Evaluate the manufacturer’s design process and engineering team to determine if they truly understand the specific requirements of cannabis.

Request detailed information about their engineering approach to critical cannabis cultivation challenges like light deprivation, humidity control in dense canopies, and CO2 enrichment. Their designs should demonstrate understanding of issues like preventing microclimates, managing air movement to prevent mold and mildew, and creating appropriate worker flow that minimizes contamination risks.

I once worked with a client who initially chose a manufacturer based largely on price. Six months after installation, they discovered their greenhouse couldn’t maintain proper environmental conditions during summer months because the engineering team had used standard agricultural calculations rather than accounting for the higher transpiration rate of mature cannabis plants. The retrofit costs exceeded what they would have spent on a properly designed system initially.

Support Infrastructure and Ongoing Services

The strongest greenhouse manufacturers offer comprehensive support beyond installation. Evaluate their service network, technical support availability, and training programs to ensure you’ll have assistance when needed.

Ask about their response time for emergency situations, availability of replacement parts, and preventative maintenance programs. The best manufacturers will have dedicated support teams familiar with cannabis cultivation challenges who can provide rapid assistance when environmental systems face issues. They should also offer comprehensive training for your staff on operating specialized cannabis greenhouse systems effectively.

During a critical power failure at one of our facilities, our greenhouse manufacturer had a technician on-site within hours to help restart environmental systems and preserve our crop. This level of responsive support prevented what could have been a seven-figure loss. When evaluating potential partners, ask specific questions about their emergency response protocols and past examples of crisis management for clients.

What Does a Turnkey Cannabis Greenhouse Solution Typically Include?

Many new cannabis cultivators underestimate the complexity of greenhouse systems needed for successful production. This knowledge gap leads to undersized or incomplete facilities that compromise crop quality and yield.

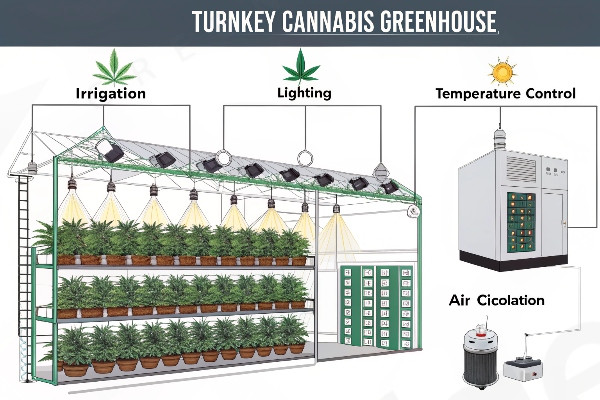

A comprehensive turnkey cannabis greenhouse solution includes structural components designed for cannabis loads, specialized light deprivation systems, zoned environmental controls, irrigation and fertigation systems, supplemental lighting, and integrated security features. These systems work together to create optimal conditions throughout all growth stages.

When I first started designing cannabis-specific greenhouses, most cultivators were adapting general horticultural structures with mixed results. Today, our turnkey solutions address every aspect of cannabis production from propagation through harvest. The most successful operations typically implement comprehensive systems rather than piecemeal solutions.

Structural Components with Cannabis-Specific Design

The greenhouse structure itself must be engineered specifically for cannabis cultivation requirements. Cannabis plants can become significantly heavier than many traditional greenhouse crops, particularly during flowering stages.

A proper cannabis greenhouse structure features reinforced truss systems to support both the crop load and additional equipment like lighting and fans. The covering materials should be selected based on light transmission requirements for cannabis, often utilizing diffused light materials to prevent hotspots while maximizing photosynthesis. The structure should also accommodate crop heights of 6-8 feet or more depending on cultivation methods.

Last year, I consulted on a project where the structure had been designed for tomato production and subsequently used for cannabis. The trusses began showing stress signs within months because they weren’t engineered for the combined weight of mature cannabis plants and the extensive supplemental lighting system required. The grower ultimately had to reinforce the entire structure at significant expense and lost production time.

Light Deprivation and Supplemental Lighting Systems

Cannabis flowering is triggered by specific light cycles. A turnkey solution must include effective light deprivation systems for photoperiod control and supplemental lighting for consistent production.

Automated blackout systems should provide 100% light deprivation with reliable mechanical components and overlap seals to prevent light leaks. These systems should integrate with environmental controls to prevent temperature spikes when deployed. Supplemental lighting systems should deliver appropriate spectrum and intensity for cannabis, with fixtures designed specifically for greenhouse environments and proper mounting systems to ensure uniform coverage.

In our Thailand facility, we implemented a dual-layer light deprivation system with automated controls that maintained perfect 12/12 flowering cycles despite being located near the equator with challenging natural daylight hours. The system included built-in redundancies to prevent mechanical failures from disrupting critical flowering periods, which had caused significant losses in the client’s previous facility.

Environmental Control Systems

Cannabis requires precise environmental control throughout its lifecycle. A turnkey solution must include integrated systems for managing temperature, humidity, CO2 levels, and air movement.

Look for solutions that include multiple cooling methods (such as evaporative cooling, mechanical cooling, and natural ventilation), dehumidification systems sized for cannabis transpiration rates, CO2 enrichment with proper distribution, and multi-layered air circulation systems. These systems should operate from a centralized controller with remote monitoring capabilities and automated responses to changing conditions.

When we designed a 40,000 sq ft facility in Michigan, we implemented a climate control system with four redundant cooling methods, dedicated dehumidification that could extract over 600 gallons of water daily from the growing environment, and variable-speed air circulation that adjusted automatically based on plant developmental stage. This comprehensive approach maintained optimal vapor pressure deficit throughout all growing zones regardless of outside conditions.

Water and Fertigation Systems

Cannabis requires precise water and nutrient delivery. Turnkey solutions should include complete irrigation and fertigation systems designed specifically for cannabis cultivation.

These systems typically include water storage, treatment options (reverse osmosis, UV sterilization, etc.), automated nutrient dosing, irrigation zones corresponding to plant development stages, and recirculation capabilities where appropriate. The systems should provide uniform distribution through appropriate emitter selection and pressure regulation, with monitoring for both delivery volumes and runoff composition.

For a recent project in Arizona, we designed a water system that included 100,000 gallons of storage, multi-stage filtration, automated pH and EC adjustment, zone-specific fertigation recipes, and real-time monitoring that alerted growers to any deviations from targets. This precision allowed them to reduce fertilizer costs by 23% while improving plant health and yield consistency.

Security Integration and Compliance Features

Cannabis facilities require specific security features for both regulatory compliance and crop protection. Turnkey solutions should address these requirements comprehensively.

Security features typically include access control systems, video surveillance coverage meeting regulatory requirements, perimeter security, and intrusion detection. These systems should integrate with the greenhouse management platform for unified control and monitoring. Additional compliance features might include odor control systems, waste management solutions, and record-keeping tools that satisfy local regulations.

When developing a facility in a strictly regulated market, we implemented a comprehensive security solution that included over 60 cameras with 60-day recording capacity, biometric access controls for sensitive areas, motion detection throughout the facility, and an odor mitigation system that prevented any detectable cannabis odor beyond property boundaries—all integrated into a single management platform accessible to both operators and regulators as required.

Comparing Greenhouse Costs: Factors Influencing Your Investment in Cannabis Cultivation?

Many cannabis entrepreneurs focus primarily on initial construction costs, overlooking the long-term operational expenses and revenue implications of their greenhouse design choices. This narrow perspective often leads to costly modifications later.

Cannabis greenhouse investments range from $65 to $300+ per square foot depending on design sophistication, environmental control capabilities, and automation level. While basic structures cost less initially, advanced systems typically deliver higher yields, better quality, and lower operational costs over time through labor savings and resource efficiency.

Earlier in my career, I worked with a client who insisted on minimizing upfront investment, opting for a basic greenhouse with manual controls and minimal automation. Within two years, they had spent more retrofitting the facility than they would have investing in appropriate systems initially. More importantly, they lost significant market opportunity during the modifications.

Understanding the true cost implications of greenhouse investments requires looking beyond initial construction expenses to consider operational efficiency, crop quality, and production consistency. The most successful operations typically find a balance between upfront investment and long-term returns.

Understanding Cost Categories in Greenhouse Construction

Cannabis greenhouse costs fall into several distinct categories that should be evaluated separately: structural components, environmental systems, cultivation equipment, and automation/control technologies.

Structural costs typically range from $30-90 per square foot depending on materials, design sophistication, and local building requirements. Environmental systems (heating, cooling, dehumidification) represent $20-100+ per square foot based on performance capabilities and redundancy levels. Cultivation equipment (benching, irrigation, lighting) adds another $15-80 per square foot. Finally, automation and controls range from $5-40+ per square foot depending on sophistication and integration depth.

When analyzing proposals from different manufacturers, ensure they provide detailed breakdowns of costs in each category rather than just total figures. This allows for meaningful comparisons and helps identify where potential manufacturers might be cutting corners or where premium features actually deliver value. For example, spending an additional $15 per square foot on advanced dehumidification often pays for itself within 12-18 months through disease prevention and yield improvements.

Regional Climate Considerations and Construction Requirements

Your location significantly impacts appropriate greenhouse design and cost. Different climates require different structural and environmental specifications to maintain optimal cannabis growing conditions.

In northern regions with cold winters and snow loads, stronger structures with better insulation and robust heating systems are essential, potentially adding $30-50 per square foot compared to more temperate regions. Hot, humid locations require more sophisticated cooling and dehumidification, often adding $25-40 per square foot. Regions with extreme weather events need reinforced construction to withstand high winds or seismic activity.

I recently compared two nearly identical cannabis greenhouse projects—one in Michigan and one in California. The Michigan facility required an additional investment of approximately $750,000 for enhanced insulation, snow load capacity, and heating infrastructure. However, this investment reduced operating costs by approximately $200,000 annually compared to a less insulated design, delivering complete ROI within four years while enabling year-round production in a challenging climate.

Operational Efficiency and Labor Cost Implications

Labor typically represents 30-45% of operational costs in cannabis cultivation. More sophisticated greenhouse designs can significantly reduce this expense through automation and workflow optimization.

Automated irrigation, climate control, and materials handling systems may add $25-75 per square foot to initial construction costs but can reduce labor requirements by 30-60%. These systems also typically improve consistency and reduce human error, leading to more predictable yields and quality. The labor savings alone often deliver ROI within 2-3 years, not counting improved crop performance.

When designing a 30,000 square foot facility in Oregon, we implemented advanced automation that increased the initial investment by approximately $900,000. This system reduced labor requirements from 12 full-time employees to 7, saving approximately $350,000 annually in labor costs. Additionally, the consistent environment created by the automated systems increased annual yield by approximately 15% while reducing crop loss events.

Energy Efficiency and Sustainability Considerations

Energy costs represent 20-35% of operational expenses in most cannabis greenhouses. More sophisticated designs with energy-efficient features may cost more initially but deliver significant operational savings.

Advanced greenhouse designs can incorporate features like thermal screens, energy-efficient HVAC systems, LED lighting, and intelligent controllers that reduce energy consumption by 30-50% compared to basic designs. While these features may add $20-40 per square foot to initial costs, the operational savings often deliver ROI within 3-4 years. Additionally, more efficient designs typically qualify for utility incentives and rebates that can offset 10-30% of these costs.

For a recent project in Massachusetts, we designed a highly efficient greenhouse that cost approximately $1.2 million more than a standard design. The annual energy savings exceeded $380,000, and the client received utility incentives totaling $425,000, resulting in a net payback period of just over two years. This efficiency also reduced their carbon footprint significantly, supporting their marketing as a sustainable producer.

Expansion Planning and Scalability Considerations

Many cannabis operations start smaller with plans for future expansion. The initial greenhouse design significantly impacts the cost and efficiency of these future expansions.

Modular greenhouse designs may cost 5-15% more initially but can reduce future expansion costs by 20-40% through pre-engineered connection points, expandable utility infrastructure, and compatible environmental systems. These designs also typically minimize production disruption during expansion phases, allowing continuous operation of existing facilities.

When working with a client planning a multi-phase cultivation facility, we designed a modular infrastructure system that added approximately $350,000 to the initial phase but reduced the second phase construction costs by over $1.2 million. More importantly, the design allowed the first phase to remain in full production during the expansion, preventing an estimated $2.5 million in potential lost revenue that would have occurred with a non-modular design requiring significant modifications to existing systems.

Conclusion

Selecting the right cannabis greenhouse manufacturer is a critical decision that impacts every aspect of your cultivation business. Prioritize partners with cannabis-specific experience, comprehensive design capabilities, and strong support services. The right greenhouse solution balances upfront investment with operational efficiency to create sustainable competitive advantage in this challenging industry.