Your small greenhouse dreams can turn into frozen nightmares without proper heating. Cold snaps destroy crops and waste months of hard work.

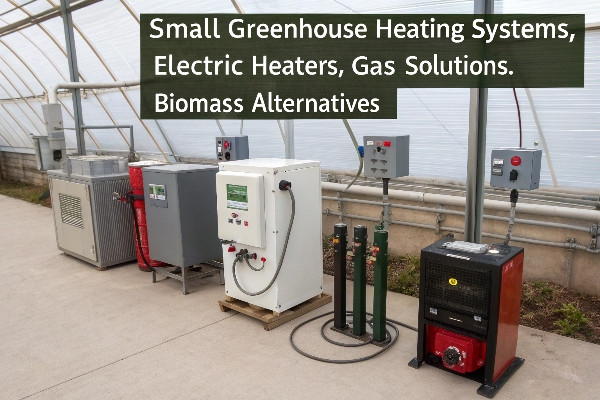

Small greenhouse heating options include electric heaters, gas systems, solar solutions, and biomass alternatives. Each system offers different benefits for temperature control, energy efficiency, and budget considerations. The right choice depends on your greenhouse size, local climate, and available utilities.

I learned this lesson the hard way during my first winter growing tomatoes. The temperature dropped to -15°C overnight, and I watched my entire crop freeze because I chose the wrong heating system. That experience taught me that heating is not just about keeping plants alive. It is about creating the right environment for growth while managing energy costs effectively.

Don’t Miss:——Commercial Hydroponic Greenhouse Systems: How Do Design, Construction, and ROI Interconnect?

You might like:——What is a Smart Greenhouse? The Ultimate Guide to Automated Growing

Are Small Electric Heaters Suitable for Greenhouses?

Electric heaters seem like the easiest solution, but many growers make costly mistakes with their selection and placement.

Electric heaters work well for small greenhouses under 100 square feet. They provide precise temperature control and quick heat distribution. However, operating costs can be high, and power outages leave plants vulnerable to freezing temperatures.

Electric heating systems offer several advantages that make them popular among small greenhouse owners. The installation process is straightforward and requires no special ventilation or gas lines. You can plug most units directly into standard electrical outlets and start heating immediately. Temperature control is precise with digital thermostats that maintain exact temperatures within one or two degrees.

The heat distribution from electric systems is clean and consistent. There are no combustion byproducts that could harm plants or create humidity problems. Electric heaters also respond quickly to temperature changes, which helps maintain stable growing conditions during variable weather.

However, the operating costs can be significant. Electricity rates vary by location, but heating a small greenhouse can add $50 to $200 to monthly utility bills during winter months. The actual cost depends on your local electricity rates, greenhouse insulation, and outside temperatures.

Power reliability becomes a critical factor with electric systems. During winter storms when heating is most needed, power outages can occur. Without backup power, temperatures can drop quickly and damage or kill plants within hours. I recommend having a backup generator or alternative heating source if you rely solely on electric heat.

| Electric Heater Type | Best For | Power Usage | Temperature Range |

|---|---|---|---|

| Ceramic Fan Heaters | Quick heating, small spaces | 1500W | 35-80°F |

| Oil-filled Radiators | Steady heat, larger areas | 1000-2000W | 40-75°F |

| Infrared Heaters | Spot heating, plant zones | 400-1500W | 45-85°F |

| Heat Mats | Seed starting, root zones | 15-100W | 65-95°F |

The key to success with electric heating is proper sizing and placement. Calculate your greenhouse volume and heat loss to determine the required wattage. Most small greenhouses need between 10 to 15 watts per square foot of floor space. Place heaters to create even air circulation and avoid creating hot spots that can stress plants.

Are Propane or Natural Gas Heaters Safe?

Gas heating raises safety concerns, but proper installation and maintenance make these systems reliable and cost-effective for greenhouse use.

Gas heaters are safe for greenhouses when properly vented and maintained. They provide efficient heating at lower operating costs than electricity. Natural gas offers consistent supply, while propane gives installation flexibility but requires tank refills.

Gas heating systems require careful consideration of safety factors and proper installation procedures. The primary concern is carbon monoxide production from incomplete combustion. All gas heaters in greenhouses must be properly vented to the outside air. Never use unvented gas heaters in enclosed greenhouse spaces, as they can produce deadly carbon monoxide and excessive moisture.

Proper ventilation involves installing intake air vents and exhaust systems that allow fresh air to enter while removing combustion gases. The venting system must be sized correctly for the heater capacity and installed according to manufacturer specifications. Regular maintenance includes cleaning burners, checking gas connections, and testing safety systems.

Natural gas offers several advantages over propane for greenhouse heating. The fuel supply is consistent and delivered through underground pipes, eliminating the need to monitor fuel levels or schedule deliveries. Natural gas typically costs less per BTU than propane, making it more economical for continuous heating. However, natural gas requires existing gas service to your property, which may not be available in rural areas.

Propane systems provide more installation flexibility since they do not require utility connections. You can install propane heaters anywhere and move them if needed. Propane burns cleaner than natural gas and produces slightly more heat per cubic foot. The main drawbacks are higher fuel costs and the need to monitor tank levels and arrange refills.

Both fuel types require proper gas line sizing and pressure regulation. Undersized gas lines can cause poor heater performance and incomplete combustion. Gas pressure must be regulated to match heater specifications, typically 11 inches of water column for natural gas and 11 or 20 inches for propane depending on the appliance.

| Gas Type | Installation Cost | Operating Cost | Availability | Safety Considerations |

|---|---|---|---|---|

| Natural Gas | High (gas line needed) | Low | Urban/suburban areas | Fixed installation, utility dependency |

| Propane | Medium | Medium-High | Universal | Tank monitoring, weather protection |

Safety equipment should include gas leak detectors, carbon monoxide alarms, and automatic shut-off valves. Install detectors near the floor since propane is heavier than air, while natural gas detectors go near the ceiling. Test all safety equipment regularly and keep a maintenance schedule for professional inspections.

Are Solar Heaters a Good Option for Small Greenhouses?

Solar heating appeals to environmentally conscious growers, but understanding the limitations and applications is essential for making informed decisions.

Solar heaters work best as supplemental heating in moderate climates. They reduce heating costs during sunny days but cannot provide reliable heat during cloudy periods or at night. Passive solar design and thermal mass storage improve effectiveness significantly.

Solar heating systems for greenhouses fall into two main categories: passive solar design and active solar heating equipment. Passive solar design uses the greenhouse structure and thermal mass to collect, store, and distribute solar energy naturally. Active systems use solar collectors, fans, and heat storage materials to capture and move heated air.

Passive solar heating starts with proper greenhouse orientation and design. Position the greenhouse with the long axis running east to west to maximize southern exposure. The south-facing wall should have maximum glazing area to collect winter sun, while the north wall can be insulated or opaque to reduce heat loss. Roof angles should be optimized for your latitude to capture the most solar energy during winter months.

Thermal mass plays a crucial role in passive solar systems. Materials like water barrels, concrete blocks, or stone walls absorb heat during the day and release it slowly at night. Water provides excellent thermal mass with high heat capacity and easy installation. Black-painted water containers work best for heat absorption and can raise nighttime temperatures by 5 to 15 degrees compared to greenhouses without thermal mass.

Active solar heating systems use solar air collectors to heat air that is then circulated through the greenhouse. These systems can include fans, ducts, and heat exchangers to improve efficiency. Solar air heaters work well during sunny days but provide no heat at night or during cloudy weather. They work best as supplemental heating combined with backup systems.

Ground-source heat pumps represent another solar-related technology that uses stable ground temperatures for heating and cooling. These systems are expensive to install but provide consistent heating capacity regardless of weather conditions. They work well in moderate climates where ground temperatures remain above freezing.

The effectiveness of solar heating depends heavily on local climate conditions. Areas with consistent winter sunshine and moderate temperatures see the best results. Regions with frequent cloudy weather or extreme cold temperatures need backup heating systems to maintain adequate growing conditions.

| Solar Heating Method | Initial Cost | Operating Cost | Climate Suitability | Backup Required |

|---|---|---|---|---|

| Passive Design | Low-Medium | None | Moderate zones | Yes |

| Solar Air Heaters | Medium | Low | Sunny regions | Yes |

| Thermal Mass | Low | None | All climates | Yes |

| Ground Source Heat Pump | High | Low | Moderate zones | No |

Cost-effectiveness varies significantly based on local energy prices and available solar resources. Calculate payback periods by comparing solar system costs to conventional heating expenses over 10 to 20 years. Include maintenance costs and potential equipment replacement in your calculations.

How to Choose a Heating Solution for a Small Greenhouse on a Budget?

Budget constraints often determine heating choices, but smart planning can provide effective heating without breaking the bank.

Budget heating solutions include zone heating, thermal mass storage, insulation improvements, and combination systems. Start with proper insulation, add thermal mass, then choose the most cost-effective heating method for your local conditions and utility costs.

Budget-conscious heating starts with reducing heat loss through improved insulation and weatherproofing. Many small greenhouses lose more heat through poor construction than they need to replace with heating systems. Address air leaks around doors, windows, and foundation areas first. Use weatherstripping, caulk, and plastic sheeting to seal gaps that allow cold air infiltration.

Insulation systems become crucial for energy efficiency and cost control. In our experience at CFGET, we design commercial greenhouses with comprehensive insulation strategies. Top insulation reduces rapid heat dissipation through the roof area, which is typically the largest source of heat loss. We use thermal curtains and blanket systems that can be deployed automatically during cold nights.

Four-sided insulation protects greenhouse interiors during extreme weather conditions. Thermal curtains on walls create an insulating air space that significantly reduces heat transfer. The combination of top and side insulation can reduce heating costs by 30 to 50 percent compared to single-layer covering systems.

Our greenhouse designs often include external wind barriers and slopes that provide additional insulation benefits. These design features create dead air spaces around the greenhouse structure that reduce wind-driven heat loss. For film-type greenhouses, external barriers create a double-layer insulation effect that improves thermal performance without adding internal equipment.

Zone heating offers another budget-friendly approach that focuses heating where plants need it most. Instead of heating the entire greenhouse air space, direct heat to plant root zones or specific growing areas. Soil heating cables, heat mats, and low-level heating systems can maintain plant growth temperatures while allowing air temperatures to drop slightly.

Combination heating systems balance initial costs with operating efficiency. A primary heating system handles most heating needs, while a secondary system provides backup protection during extreme weather. This approach reduces the size and cost of the primary system while ensuring plant protection during emergencies.

| Budget Strategy | Implementation Cost | Annual Savings | Payback Period | Difficulty Level |

|---|---|---|---|---|

| Insulation Upgrade | $200-500 | $150-400 | 1-3 years | DIY Possible |

| Thermal Mass Addition | $100-300 | $50-200 | 2-4 years | Easy DIY |

| Zone Heating | $150-400 | $100-300 | 2-3 years | Moderate DIY |

| Wind Barriers | $50-200 | $25-100 | 2-4 years | Easy DIY |

Timing your heating system purchase and installation can also impact costs. Buy equipment during off-season sales when demand is lower. Spring and summer months often offer better prices on heating equipment. Plan installation during mild weather when you have time to test and adjust systems before they are needed.

Maintenance and operational practices affect long-term costs significantly. Keep heating systems clean and properly adjusted for maximum efficiency. Use programmable thermostats to avoid overheating during mild weather. Consider setback temperatures at night when plants can tolerate slightly cooler conditions.

Energy monitoring helps optimize heating costs by tracking usage patterns and identifying opportunities for improvement. Simple monitoring can show which heating strategies work best for your specific conditions and help you make informed decisions about system upgrades or modifications.

Conclusion

Choose heating systems based on your greenhouse size, local climate, utility availability, and budget constraints for optimal plant growth and energy efficiency.

I have seen many growers succeed with different heating approaches, from simple electric heaters to sophisticated combination systems. The key is matching your heating choice to your specific needs and conditions. Start with good insulation, add thermal mass where possible, and select heating equipment that provides reliable temperature control within your budget.

The investment in proper heating pays dividends through extended growing seasons, better plant health, and more consistent harvests. With 28 years of greenhouse experience, we at CFGET understand that heating is not just about surviving winter. It is about creating optimal growing conditions that help you achieve your agricultural goals year-round.