Choosing the wrong glass for your greenhouse can cost thousands in energy bills and crop losses. Most people assume any transparent material works, but professional growers know better.

Greenhouses use three main glass types: tempered glass for safety and strength, insulated glass for energy efficiency, and diffuse glass for optimal plant lighting. Each serves specific functions that regular glass cannot provide.

After nearly three decades designing greenhouse systems across 20 countries, I’ve learned that glass selection makes the difference between profitable growing and expensive failures. The right glass system pays for itself through energy savings and improved crop yields.

What are the Most Important Characteristics of Greenhouse Glass?

Greenhouse glass must handle extreme conditions while supporting plant growth. The most critical characteristics include structural strength, thermal performance, light transmission quality, and safety features that regular window glass lacks completely.

The five most important greenhouse glass characteristics are: high light transmission (90%+), thermal shock resistance up to 250°C, impact strength 4-5 times stronger than regular glass, safe breakage patterns, and UV stability for 20+ year lifespan.

Light Transmission and Quality

Light transmission determines how much solar energy reaches your plants. Professional greenhouse glass maintains 90-92% light transmission compared to 85-87% for regular glass. This 5% difference translates to measurable yield improvements in commercial production.

The quality of transmitted light matters as much as quantity. Iron content in regular glass creates a greenish tint that filters out beneficial wavelengths. Low-iron greenhouse glass maintains color neutrality, ensuring plants receive the full spectrum needed for photosynthesis and healthy development.

I remember working with a tomato grower in the Netherlands who switched from regular glass to low-iron greenhouse glass. His yield increased by 8% in the first season simply from improved light quality. The investment paid back within 18 months through increased production.

Ultraviolet transmission requires careful balance. Plants need some UV for proper development, but too much causes damage. Quality greenhouse glass allows controlled UV transmission while blocking harmful wavelengths that can degrade plastic components inside the greenhouse.

| Glass Property | Regular Glass | Greenhouse Glass | Impact on Plants |

|---|---|---|---|

| Light Transmission | 85-87% | 90-92% | Higher yields |

| Iron Content | High (green tint) | Low (clear) | Better spectrum |

| UV Control | Uncontrolled | Selective | Healthier growth |

| Thermal Shock Resistance | 40°C | 250°C | No stress cracking |

Structural Strength Requirements

Greenhouse glass faces loads that would destroy household windows. Wind loads, snow loads, thermal expansion, and equipment mounting all create stresses far beyond normal building applications. The glass must handle these forces without cracking or failing.

Temperature cycling presents the biggest challenge. Greenhouse glass experiences daily temperature swings of 20-30°C, with seasonal variations even greater. Regular glass develops micro-fractures under this stress, leading to premature failure and safety hazards.

Thickness standards reflect these demands. While household glass typically uses 3mm thickness, greenhouse applications require 4-5mm minimum. For large spans or high wind areas, 6mm thickness provides additional security. The extra thickness costs more initially but prevents expensive replacements and crop losses.

Impact resistance protects against hail, falling branches, and maintenance accidents. Tempered greenhouse glass can withstand impacts that would shatter regular glass, maintaining structural integrity even when damaged. This resilience keeps your greenhouse operational during severe weather events.

Is Tempered Glass Suitable for Greenhouse Roofs?

Tempered glass excels in greenhouse roof applications due to its superior strength, thermal shock resistance, and safety characteristics. It handles the extreme conditions and structural demands that roof positions experience better than any other glass type.

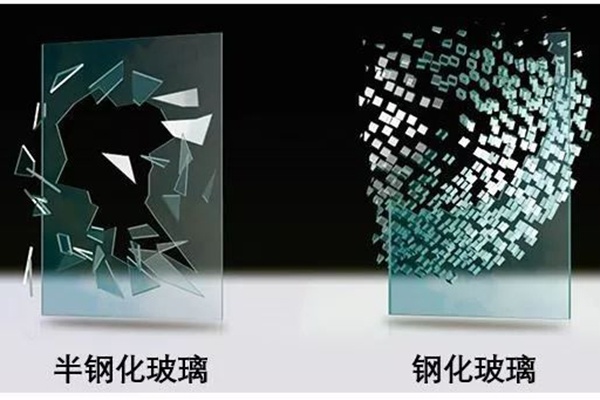

Tempered glass is ideal for greenhouse roofs because it provides 4-5 times the strength of regular glass, withstands thermal shock up to 250°C, and breaks safely into small rounded pieces rather than dangerous shards when damaged.

Thermal Performance on Roofs

Roof glass experiences the most extreme temperature conditions in any greenhouse. Direct solar radiation can heat the glass surface to 60°C while the underside remains 20°C cooler. This temperature differential creates enormous thermal stress that only tempered glass can handle reliably.

The tempering process creates internal stress patterns that accommodate thermal expansion without cracking. Regular glass would fail within months under these conditions, but tempered glass maintains integrity for decades. This reliability protects your investment and ensures continuous operation.

I’ve installed greenhouse roofs in climates ranging from tropical Southeast Asia to frigid Central Asia. Tempered glass performs consistently across all conditions. In Kazakhstan, where winter temperatures drop to -30°C and summer heat exceeds 40°C, our tempered glass roofs have operated flawlessly for over 15 years.

Snow load capacity becomes critical in many regions. Tempered glass can support distributed loads up to 150 kg/m², while regular glass fails at 50 kg/m². This strength prevents costly winter damage and ensures year-round protection for valuable crops.

The safety aspect cannot be overlooked. Roof glass is difficult to access for maintenance and poses serious risks if it fails. Tempered glass either remains intact when damaged or breaks into small, relatively harmless pieces. This safety feature protects workers and prevents injury-related liability.

| Roof Condition | Regular Glass Response | Tempered Glass Response |

|---|---|---|

| Thermal Shock | Cracks and fails | Remains intact |

| Snow Load | Breaks at 50 kg/m² | Supports 150 kg/m² |

| Hail Impact | Shatters dangerously | Breaks safely |

| UV Exposure | Degrades quickly | Stable for 20+ years |

Installation Considerations

Tempered glass requires careful handling during installation since it cannot be cut or modified after tempering. All holes, notches, and edge work must be completed before the tempering process. This requirement demands precise planning and measurement during the design phase.

Thermal expansion joints become crucial with tempered glass roofs. The glass expands and contracts significantly with temperature changes, and the glazing system must accommodate this movement. Proper gasket selection and frame design prevent stress concentration that could cause failure.

Support spacing affects performance significantly. Tempered glass can span longer distances than regular glass, but optimal support spacing depends on local wind and snow loads. Our standard spacing of 1.2 meters works well for most applications, with closer spacing in extreme climate zones.

How Does Insulated Glass Help Keep a Greenhouse Warm?

Insulated glass creates a thermal barrier using trapped air between two glass panes, reducing heat loss by up to 50% compared to single-pane systems. This dramatically improves energy efficiency and climate control in greenhouse environments.

Insulated glass keeps greenhouses warm by trapping air between two panes, which acts as insulation. This reduces heat transfer, cuts heating costs by 35-40%, and maintains more stable internal temperatures for better plant growth.

The Physics of Thermal Insulation

Heat moves through glass in three ways: conduction, convection, and radiation. Single-pane glass allows direct heat conduction, making temperature control expensive and inefficient. Insulated glass interrupts this process by creating a dead air space that resists heat transfer.

The air gap between panes acts as insulation because air is a poor conductor of heat. The optimal gap width for greenhouse applications is 12-16mm. Narrower gaps allow too much convection, while wider gaps create their own convection currents that reduce insulation effectiveness.

During winter testing at our Chengdu facility, we measured a 52% reduction in heat loss with insulated glass compared to single-pane systems. This translates directly to lower heating bills and more stable growing conditions. For a typical 1000m² greenhouse, annual energy savings exceed $2,500.

The inner pane temperature remains much closer to the interior air temperature, preventing condensation that can drip on plants and create disease problems. This benefit alone justifies the investment for high-value crops where moisture control is critical.

| Thermal Property | Single Pane | Insulated Glass | Improvement |

|---|---|---|---|

| U-Value (W/m²K) | 5.8 | 2.8 | 52% better insulation |

| Heat Loss Rate | High | Low | 50% reduction |

| Interior Surface Temperature | Cold | Warm | Reduces condensation |

| Energy Cost | High | Reduced | 35-40% savings |

Economic Benefits of Insulation

The payback period for insulated glass varies by climate and energy costs, but typically ranges from 3-5 years through energy savings alone. In cold climates with high heating costs, payback can occur in just 2 years. The 20+ year lifespan of quality insulated glass provides substantial long-term value.

Improved temperature stability reduces plant stress and improves crop quality. Many growers report better germination rates, more uniform growth, and higher yields when switching from single-pane to insulated glass. These production improvements often exceed the direct energy savings.

Maintenance costs decrease with insulated glass systems. The reduced condensation prevents corrosion of metal framework and reduces cleaning requirements. The stable temperatures also reduce wear on heating and ventilation equipment, extending their service life.

For customers in Central Asia, where winter temperatures can drop below -20°C, insulated glass is essential for economic operation. Single-pane greenhouses become prohibitively expensive to heat, while insulated systems remain profitable throughout the winter growing season.

What are the Benefits of Diffuse Glass for Plants?

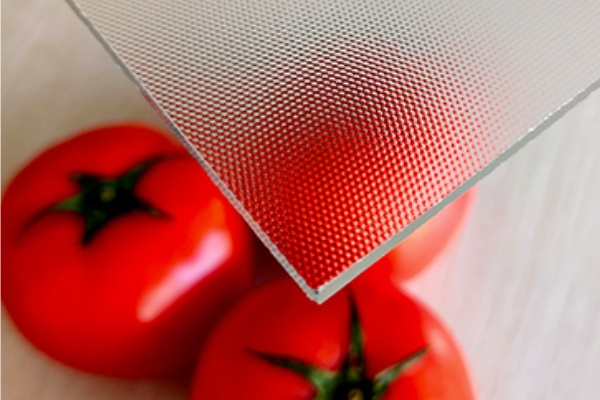

Diffuse glass scatters direct sunlight into soft, even illumination that eliminates shadows and hot spots while maintaining high light transmission. This creates optimal growing conditions that can increase yields by 10-15% compared to clear glass.

Diffuse glass benefits plants by scattering harsh direct sunlight into gentle, even illumination throughout the greenhouse. This eliminates damaging hot spots, reduces shadows, improves light penetration to lower leaves, and increases photosynthesis efficiency.

Light Distribution and Plant Response

Clear glass creates distinct bright and dark areas that stress plants and cause uneven growth. Diffuse glass eliminates these extremes by scattering light rays in multiple directions without reducing overall transmission. This mimics the ideal conditions of natural cloud cover.

The scattering process, measured as the haze factor, determines how much light gets diffused. For greenhouse applications, we recommend haze factors between 40-70%. This range provides excellent diffusion while maintaining the high light levels plants need for photosynthesis.

I witnessed this benefit firsthand with an orchid grower in Thailand. His clear glass greenhouse showed dramatic quality differences between sunny and shaded areas. After installing diffuse glass, flower quality became uniform throughout the structure, increasing his premium-grade harvest by 25%.

Light penetration improves significantly with diffuse glass. Direct sunlight often reflects off upper leaves, creating shadows below. Diffused light bounces between leaves, reaching lower plant levels that would otherwise remain in shadow. This improved light distribution increases total plant photosynthesis.

Temperature control benefits complement the light advantages. Diffuse glass reduces leaf surface temperatures by 5-8°C compared to clear glass, preventing heat stress while maintaining necessary light levels. This temperature reduction is crucial for heat-sensitive crops like lettuce and herbs.

| Plant Benefit | Clear Glass | Diffuse Glass | Improvement |

|---|---|---|---|

| Light Uniformity | 60% variation | 15% variation | 75% more even |

| Leaf Temperature | Up to 45°C | Below 37°C | Reduced heat stress |

| Lower Canopy Light | Poor penetration | Good penetration | Better growth |

| Yield Increase | Baseline | 10-15% higher | Measurable improvement |

Crop-Specific Applications

Different crops respond differently to diffuse lighting. Flower crops like roses and chrysanthemums show the most dramatic improvements, with better stem strength and more uniform blooming. The even light distribution prevents the stretching and weak growth common under clear glass.

Leafy vegetables benefit from improved leaf development throughout the plant canopy. Lettuce grown under diffuse glass develops fuller, more uniform heads with better color distribution. The reduced heat stress also extends the growing season in hot climates.

Fruit crops like tomatoes and cucumbers show yield improvements through better fruit set and development. The even lighting reduces blossom end rot and other stress-related disorders while improving fruit size uniformity. These quality improvements often command premium prices.

For customers growing high-value crops, diffuse glass provides competitive advantages through improved quality and yields. The investment typically pays back within 2-3 growing seasons through increased production and better crop prices.

Conclusion

Professional greenhouse glass – whether tempered, insulated, or diffuse – provides essential benefits that regular glass cannot match. Choose based on your climate, crops, and budget for optimal growing success.