Many tomato projects in Mexico start with a “cheap structure” plan. Then heat, humidity swings, pests, and uneven climate reduce yield and grade. The payback gets slow.

For commercial tomatoes in Mexico, the best greenhouse type is usually a multi-span film greenhouse (mid-tech) or a Venlo-style glass greenhouse (high-tech), depending on your climate zone, market target, and how stable you need year-round quality to be.

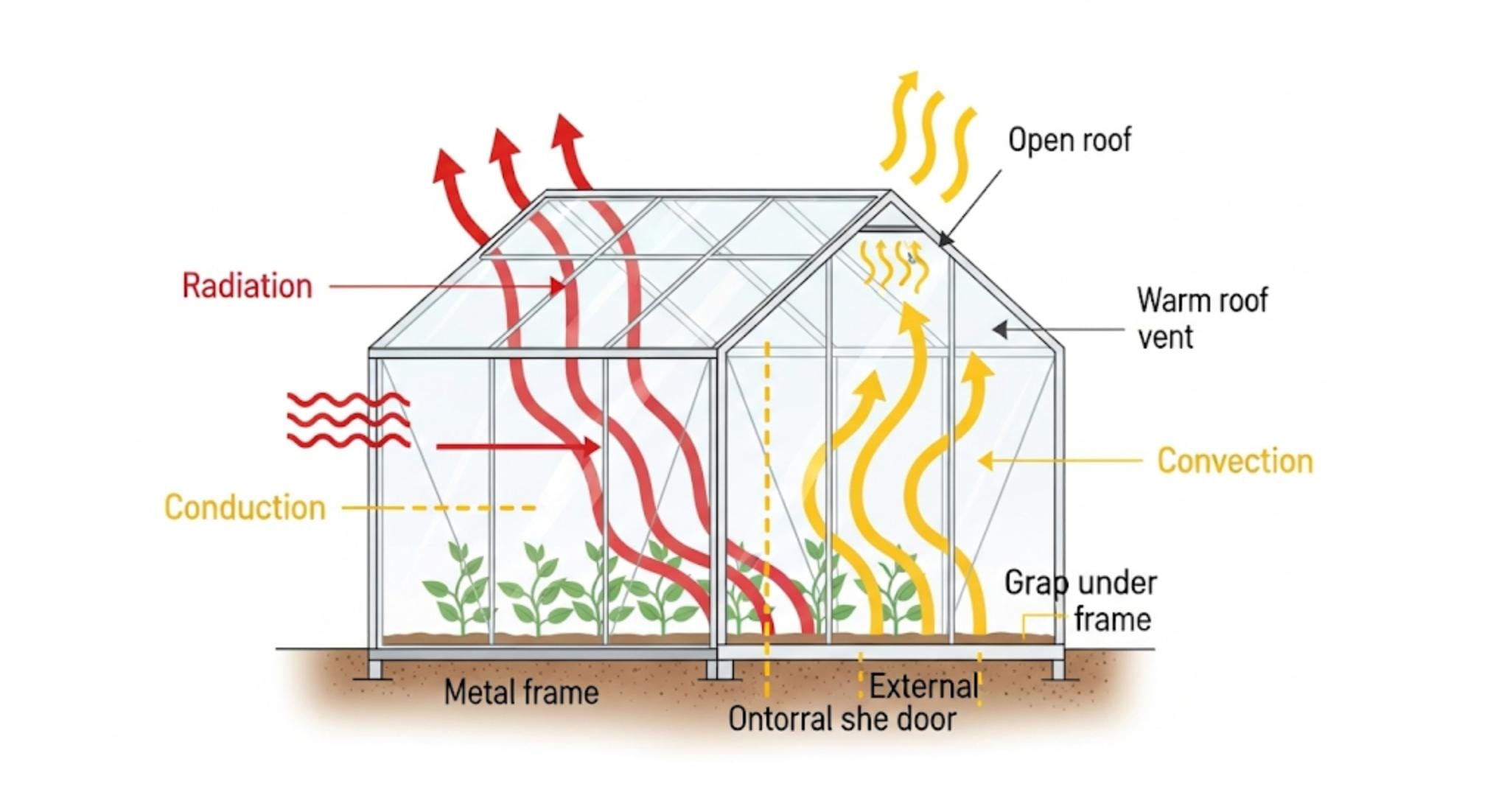

A tomato greenhouse designed for stable commercial output.

I write this from a decision and engineering viewpoint. I do not believe “one greenhouse fits all.” Mexico is a major tomato producer and exporter. Regions like Sinaloa and Sonora have been central in fresh tomato export flows for a long time, so the greenhouse choice must match real heat load and real market pressure. USDA ERS has also documented how Mexico’s tomato export regions concentrate seasonally, which matters when you plan production windows.

Why is “best greenhouse type” a decision problem, not a structure question?

People often ask for a single best greenhouse type. That question is too broad.

The “best” greenhouse for tomatoes only exists after I define climate stress, market requirements, production system, and operating cost limits.

A simple decision process reduces costly mistakes.

Dive deeper

Most top-ranking pages compare greenhouse types by shape and covering material. That is not how commercial tomato profit works. Tomatoes are a high-value crop, but they punish instability. If temperature, humidity, and airflow vary across bays, I get uneven fruit size, uneven ripening, more disease pressure, and more labor.

A stronger approach is to treat greenhouse selection as a risk and cost control decision. Climate risk is not theoretical. FAO – Food and Agriculture Organization of the United Nations highlights that heat stress and climate variability are key threats to crop productivity. Tomatoes are sensitive to heat stress during flowering and fruit set. So “best greenhouse type” is really “best risk control system.”

Mexico also has strong export-driven tomato production. USDA ERS (Mexican Greenhouse Tomato Industry – PDF) documents how major producing/export regions have historically concentrated in states like Sinaloa and Sonora. This matters because an export-focused operation usually needs tighter quality and volume stability than a local wholesale model.

So I do not start with “glass vs film.” I start with:

- Do I sell to export buyers or local markets?

- Do I need year-round stability or seasonal advantage?

- Is my limiting factor heat, humidity, wind, or winter nights?

- Can my power and water supply support long cooling runtimes?

Only after that do I choose a greenhouse type.

Which greenhouse types are the real contenders for commercial tomatoes in Mexico?

Tomatoes narrow the options. Not every greenhouse type is a serious commercial tool.

In Mexico, the main contenders for commercial tomatoes are multi-span film greenhouses (most common mid-tech), multi-span PC greenhouses (specific cases), and Venlo-style glass greenhouses (high-tech, premium stability).

Dive deeper

Here is the simplest truth I use: tomatoes require control and uniformity. Single tunnels can grow tomatoes, but commercial tomato success needs scale and consistent climate.

Option 1: Multi-span film greenhouse (mid-tech)

This is often the best balance for Mexico when I want scale, fast construction, and controllable cost. It supports:

- large ventilation openings

- shading integration

- fan-pad cooling in dry regions

- insect netting and compartment zoning

Option 2: Venlo-style glass greenhouse (high-tech)

This becomes “best” when my business needs year-round consistency and premium grade. Glass plus strong automation can improve:

- light transmission (important for winter production)

- tighter control

- better uniformity at scale

But it comes with higher CAPEX and usually higher complexity.

Option 3: Multi-span PC greenhouse

This can be useful in some cases, but for Mexico tomatoes it is usually chosen only when the project needs specific insulation, hail resistance, or a certain durability goal.

The missing point on many SERP pages is that the type is not enough. A “multi-span film greenhouse” can be low-tech or mid-tech or close to high-tech depending on how I design vents, shading, cooling, and automation. That is why I treat greenhouse type as a platform, not a final answer.

If you want a fast way to explore core platforms, CFGET’s product overview pages can help you map options:

What is the #1 failure mode in Mexico: heat load, humidity, or airflow?

In Mexico tomato projects, most failures start with climate mismatch.

The most common failure is not “no cooling.” It is cooling and ventilation that cannot keep up with peak heat loads or humidity limits, so the greenhouse becomes unstable for hours every day.

Dive deeper

Many “best greenhouse type” articles skip the real question: can this type maintain a stable tomato climate during the hottest weeks?

If I depend on evaporative cooling, I must respect its limits. University of Florida IFAS Extension explains the performance logic of fan-and-pad systems and how humidity affects temperature drop. If humidity is high, evaporative cooling cannot deliver large reductions. That means the “best greenhouse type” in a hot-humid zone must rely more on heat load reduction (shading, ventilation design, airflow path) than on evaporative cooling alone.

Airflow is often the hidden bottleneck. Fans may be installed, but effective air exchange is lower than expected due to pressure losses, poor sealing, or short-circuiting airflow. Fan testing and airflow standards from ASABE are valuable because they explain why rated capacity is not always real delivered performance.

This is also where greenhouse geometry matters. Multi-span designs can scale, but if the airflow path is not correct, the exhaust side becomes much hotter than the intake side. For tomatoes, that means uneven fruit set and uneven grade. When I design for commercial tomatoes, I treat uniformity as a financial metric, not a comfort metric.

If your goal is strong stability with less manual intervention, automation becomes part of the “type choice.” A mid-tech multi-span with staged control can outperform a poorly controlled high-tech structure. For that reason, I often connect greenhouse selection with automation planning like:

- Smart Auto & Control

- Semi-Closed Greenhouse (when climate and budget justify it)

Which “best” should I optimize: lowest CAPEX, lowest cost per kg, or highest grade stability?

Most people optimize the wrong target.

For commercial tomatoes, the best greenhouse type is the one that minimizes total cost per kilogram while keeping grade stability high, not the one with the lowest build price.

Dive deeper

I use a three-best framework, because “best” depends on your business model:

Best #1: Fast build + faster payback (often multi-span film, basic-mid tech)

This is common when I target seasonal export windows or local wholesale markets. The structure cost is lower, and I can scale area faster. The risk is climate instability if ventilation and shading are under-designed.

Best #2: Best total cost per kg (often multi-span film, well-designed mid-tech)

This is the “sweet spot” for many Mexico tomato projects. With proper vents, insect netting strategy, shading, and staged cooling control, I can achieve strong yield stability without the full cost of glass.

Best #3: Best grade stability and year-round supply (often Venlo glass, high-tech)

If I sell to premium buyers or need contracts with strict quality metrics, high-tech glass plus high-level automation may win. But the operation must support higher energy and maintenance complexity.

Energy and operating cost are real decision drivers. Controlled environment systems depend heavily on energy use patterns. USDA ERS discusses controlled environment agriculture trends and the importance of operating realities. I also use energy planning resources from Cornell CEA to keep the discussion practical and avoid “magic performance claims.”

This is why greenhouse type selection must include OPEX, not only CAPEX:

- electricity for fans, pumps, controls

- water usage and water quality maintenance

- labor needed for crop management under unstable climate

- yield loss risk during heat waves

How do I match greenhouse type to Mexico’s most common tomato production reality?

Mexico is not one climate. So I choose greenhouse type by zone and target.

For many commercial tomato projects in Mexico, a well-designed multi-span film greenhouse is the most practical “best” choice, unless the business model demands premium year-round stability where Venlo glass becomes justified.

Dive deeper

I use climate data to avoid guessing. The World Bank Climate Change Knowledge Portal is useful because it helps confirm temperature and seasonality patterns. Then I decide whether my main challenge is:

- extreme heat and radiation

- humidity and disease pressure

- winter night temperatures

- wind and structural load

I also consider market orientation. Export-driven tomato operations often focus on consistent grade and timing. The long-term export structure has been studied in documents like the USDA ERS Mexican Tomato Industry PDF, which is one reason I treat export timing and region as part of greenhouse selection logic.

Now I turn that into a decision table:

| Decision factor | If YES | Best greenhouse direction |

|---|---|---|

| Need year-round premium grade | Yes | Venlo-style glass + high automation |

| Need fast scale and mid cost | Yes | Multi-span film (mid-tech) |

| Main risk is hot-humid limitations | Yes | Multi-span film + large vents + shading priority |

| Main risk is dry heat | Yes | Multi-span film + fan-pad + airflow design |

| Power is unstable | Yes | Reduce reliance on energy-heavy cooling; focus shading + natural ventilation |

| Need tight labor efficiency | Yes | Automation and staged control become mandatory |

This is where CFGET’s internal pages support buyer navigation and conversion:

- Commercial Greenhouse for platform selection

- Growing Systems to match tomatoes with hydroponic or substrate approaches

- Contact Us to request a climate-based recommendation set

Conclusion

There is no single best greenhouse for tomatoes in Mexico. The best choice depends on climate zone, export or local market goals, and your tolerance for OPEX and complexity. I pick the type that delivers stable grade and predictable cost per kg.

External References

FAO – Climate Change and Agriculture

https://www.fao.org/climate-change/en/World Bank – Climate Change Knowledge Portal

https://climateknowledgeportal.worldbank.org/University of Florida IFAS Extension – Fan-and-Pad Evaporative Cooling

https://edis.ifas.ufl.edu/publication/AE069USDA ERS – Mexican Greenhouse Tomato Industry (PDF)

https://ers.usda.gov/sites/default/files/_laserfiche/publications/45465/15303_err2d_1_.pdfUSDA ERS – Controlled Environment Agriculture Chart of Note

https://www.ers.usda.gov/data-products/charts-of-note/chart-detail?chartId=109422Cornell University – CEA Energy Resources

https://cea.cals.cornell.edu/energy/ASABE – Agricultural Engineering Standards & Publications

https://elibrary.asabe.org/Wageningen University & Research – Greenhouse Horticulture

https://www.wur.nl/en/research-results/research-institutes/plant-research/greenhouse-horticulture.htm

Internal References (CFGET)

Commercial Greenhouse Systems

https://cfgreenway.com/greenhouse/Venlo Greenhouse

https://cfgreenway.com/venlo/Polycarbonate Greenhouse Systems

https://cfgreenway.com/polycarbonate/Smart Auto & Control Solutions

https://cfgreenway.com/solutions/smart-auto-control/Growing Systems

https://cfgreenway.com/growing-systems/

Internal Blog References (Related CFGET Articles)

Venlo Glass Greenhouse Design

https://cfgreenway.com/venlo/Semi-Closed Greenhouse Systems

https://cfgreenway.com/semi-closed/Polycarbonate Greenhouse Systems

https://cfgreenway.com/polycarbonate/Retractable Roof Greenhouses

https://cfgreenway.com/retractableroof/