Choosing the wrong greenhouse covering can destroy your entire investment within three seasons. I’ve seen million-dollar operations fail because they picked materials based on price alone.

At CFGET, our 29-year track record shows that polycarbonate excels in extreme climates while glass dominates precision agriculture. The choice depends on your specific crop-climate combination, not marketing claims.

Last month, I visited two identical tomato operations in Kazakhstan – one used glass, the other polycarbonate. The glass facility achieved 15% higher yields but spent 40% more on heating costs. This real-world example perfectly illustrates why material selection requires deep technical analysis, not surface-level comparisons. At CFGET, we’ve installed over 10,000 hectares of greenhouse systems across 20+ countries, and every successful project started with proper material matching.

Don’t Miss:——Commercial Hydroponic Greenhouse Systems: How Do Design, Construction, and ROI Interconnect?

You might like:——What is a Smart Greenhouse? The Ultimate Guide to Automated Growing

Light Transmission Truth: How Do Laboratory Values Compare to Actual Greenhouse Performance After 5 Years?

Perfect light transmission specifications become meaningless when dust storms hit your facility twice weekly. Real-world performance depends on maintenance protocols, climate conditions, and installation quality.

Glass maintains 90-92% transmission initially but drops to 70-75% without proper maintenance. Polycarbonate starts at 82-85% but its diffusion properties often deliver better crop performance than higher-transmission glass.

Photosynthetically Active Radiation Distribution Analysis

Most growers focus only on total light transmission percentages. This approach misses critical factors affecting plant growth. At CFGET, we measure PAR (Photosynthetically Active Radiation) distribution patterns throughout entire greenhouse structures. Glass creates distinct light and shadow zones due to its clarity. Plants in shadow areas receive 30-40% less light than those in direct zones.

Polycarbonate’s light diffusion properties eliminate these hot spots and shadows. Our PAR measurements in Southeast Asian installations show only 10-15% variation between brightest and darkest growing areas. This uniformity often produces higher overall yields despite lower peak light levels.

I recently analyzed data from our Vietnamese cucumber project. The polycarbonate structure achieved 98% plant uniformity compared to 85% in the adjacent glass facility. Both facilities used identical climate control and irrigation systems. The polycarbonate installation produced 12% more marketable fruit due to consistent plant development.

Light quality matters more than quantity for many crops. Glass transmits full spectrum light without alteration. Polycarbonate slightly filters UV radiation, which can benefit sensitive crops but may reduce natural pest resistance in others. Our European herb operations specifically request glass for this UV transmission advantage.

Condensation Impact on Effective Light Transmission

Laboratory transmission values ignore condensation effects. Condensation reduces effective light transmission by 20-30% during critical morning hours. Glass condensation forms large droplets that create significant light blocking. These droplets also drip onto plants, potentially spreading diseases.

Polycarbonate’s surface properties promote thin film condensation that evaporates quickly. Our Central Asian installations experience severe temperature swings causing heavy condensation. The polycarbonate facilities maintain 85-90% effective light transmission during condensation periods. Glass facilities in the same conditions drop to 60-70% effective transmission.

| Performance Factor | Glass (5-year average) | Polycarbonate (5-year average) | CFGET Field Data |

|---|---|---|---|

| Peak transmission | 90-92% | 82-85% | 500+ installations |

| Average with condensation | 75-80% | 80-83% | Morning measurements |

| Light uniformity | 60-70% | 85-90% | PAR mapping data |

| UV transmission | 95-98% | 75-80% | Spectral analysis |

| Maintenance requirement | High | Medium | Annual service records |

Climate-Specific Performance Variations

Desert installations present unique challenges. Sand erosion gradually reduces glass transmission over time. Our Saudi Arabia projects show 2-3% annual transmission loss from sand damage. Polycarbonate suffers similar erosion but maintains better overall performance due to its diffusion properties.

Coastal installations face salt spray corrosion. Glass surfaces develop mineral deposits requiring frequent cleaning. Our Australian coastal projects require monthly glass cleaning to maintain adequate light levels. Polycarbonate installations in similar conditions maintain performance with quarterly cleaning cycles.

High-altitude installations deal with intense UV exposure. Glass provides no UV protection, potentially damaging sensitive crops. Polycarbonate’s UV filtering becomes advantageous in these conditions. Our Andean flower operations specifically choose polycarbonate for UV protection while maintaining adequate growing light.

Structural Load-Bearing & Installation: What Hidden Costs Does Material Weight Add to Your Total Project Investment?

Material weight creates cascading structural requirements that can double your foundation and framework costs. Many contractors provide misleading quotes by ignoring these weight-related expenses.

Glass requires 40-50% heavier structural systems, adding $15-25 per square meter to construction costs. CFGET’s engineering analysis shows these structural costs often exceed the material price difference.

Foundation Engineering Requirements

Weight differences demand different foundation approaches. Glass installations require reinforced concrete foundations with deeper footings. Our engineering team calculates foundation loads for every project. Glass structures need foundations rated for 150-200 kg/m² compared to 80-120 kg/m² for polycarbonate systems.

Soil conditions amplify these differences. Soft soil sites require pile foundations for glass structures while polycarbonate systems often work with standard spread footings. Our Indonesian projects frequently encounter soft tropical soils. Glass installations cost 60-80% more for foundation work alone.

Foundation costs vary dramatically by region. European installations benefit from experienced concrete contractors and readily available materials. Foundation premiums for glass rarely exceed 30-40%. Central Asian projects face limited concrete expertise and material availability. Foundation cost premiums can reach 100-150% for glass systems.

Seismic requirements add complexity in earthquake-prone regions. Both materials perform well with proper engineering, but polycarbonate’s flexibility provides inherent advantages. Our Turkish installations include extensive seismic bracing for glass structures. Polycarbonate installations require much simpler seismic protection.

Framework Material and Labor Requirements

Structural steel requirements increase proportionally with covering weight. Glass installations need heavier gauge tubing, more support members, and stronger connections. Our structural calculations show 25-35% more steel required for equivalent glass spans.

Steel costs vary globally, affecting total project economics. European steel prices remain relatively stable. Southeast Asian steel markets show significant volatility. This volatility particularly impacts glass projects due to their higher steel requirements.

Installation complexity increases with heavier materials. Glass panels require specialized lifting equipment and experienced glaziers. Our installation teams need 3-4 skilled glaziers for glass projects compared to 1-2 general workers for polycarbonate installation.

Labor availability affects project scheduling and costs. European markets provide abundant skilled glaziers. Central Asian markets have limited glazing expertise, often requiring imported labor. This labor shortage can delay glass projects by 4-6 weeks while polycarbonate installations proceed with local workers.

| Installation Factor | Glass Systems | Polycarbonate Systems | CFGET Project Data |

|---|---|---|---|

| Foundation depth | 1.2-1.5m | 0.8-1.0m | Standard installations |

| Steel requirements | +35-40% | Baseline | Structural calculations |

| Installation time | 4-6 weeks | 2-3 weeks | Average project duration |

| Skilled labor needs | 3-4 glaziers | 1-2 general workers | Team requirements |

| Equipment rental | $8,000-12,000 | $3,000-5,000 | Crane and lifting costs |

Wind Load and Structural Dynamics

Different materials respond differently to wind forces. Glass panels create rigid structures with high wind resistance but require substantial framework support. Polycarbonate’s flexibility allows some movement, reducing peak loads on structural members.

Wind load calculations consider local weather patterns. Our European North Sea installations face consistent strong winds. Glass structures require extensive wind bracing and heavy foundations. Polycarbonate systems handle similar conditions with standard structural designs.

Extreme weather events increasingly affect greenhouse design. Hurricane-prone regions demand impact-resistant systems. Both materials can meet these requirements, but polycarbonate naturally provides better impact resistance. Our Caribbean installations exclusively use polycarbonate due to hurricane frequency.

Maintenance access affects long-term structural requirements. Glass cleaning requires walkways and access platforms adding structural loads. Polycarbonate’s lower maintenance needs reduce structural complexity and ongoing modification requirements.

Cost & ROI: How Do Hidden Expenses and Regional Variations Affect Your 20-Year Financial Performance?

Material costs represent only 15-20% of total greenhouse ownership expenses. Energy consumption, maintenance cycles, and replacement schedules create the real financial impact over operational lifespans.

CFGET’s 20-year cost analysis reveals glass installations cost 25-30% more initially but deliver 15-20% better energy efficiency. Polycarbonate systems require replacement after 12-15 years, fundamentally changing ROI calculations.

Energy Performance and Operating Costs

Thermal performance directly impacts operational profitability. Glass conducts heat rapidly, requiring more energy for temperature control. Our energy audits show glass structures consume 20-25% more heating energy in temperate climates. However, glass structures cool more efficiently in hot climates, reducing air conditioning costs.

Polycarbonate’s insulating properties reduce heating requirements but can increase cooling loads. Our Middle Eastern installations show 15-20% higher cooling energy use with polycarbonate compared to glass. The net energy balance depends entirely on local climate conditions and crop requirements.

Regional energy costs dramatically affect material selection economics. European installations face high energy costs making polycarbonate’s insulation valuable. Southeast Asian installations have lower energy costs but higher cooling requirements favoring glass installations.

Renewable energy integration affects long-term economics. Solar panel installations work better on glass structures due to structural strength. Our renewable energy projects increasingly specify glass for combined growing and power generation facilities.

Maintenance Cycle Economics

Maintenance requirements vary significantly between materials and climates. Glass requires minimal maintenance in dry climates but needs frequent cleaning in humid or dusty conditions. Our Saudi installations clean glass panels twice weekly due to dust storms. Annual cleaning costs reach $2-3 per square meter.

Polycarbonate maintenance focuses on UV degradation and impact damage. Coastal installations require annual UV coating reapplication costing $1-2 per square meter. Interior panels may last 15+ years without treatment while exposed panels need attention every 3-5 years.

Replacement scheduling affects cash flow planning. Glass typically lasts 25-30 years with proper maintenance. Polycarbonate panels require complete replacement every 12-15 years. This replacement timing often coincides with major equipment overhauls, compounding capital requirements.

Regional maintenance capabilities influence total costs. European markets provide comprehensive service networks. Central Asian installations often struggle with spare parts availability and technical expertise. These service limitations favor more durable glass installations despite higher initial costs.

Market Value and Resale Considerations

Facility resale values depend on construction quality and remaining useful life. Glass structures typically maintain higher resale values due to longer lifespans and perceived quality. Our market analysis shows glass facilities retain 70-80% of original value after 10 years compared to 50-60% for polycarbonate structures.

Equipment compatibility affects long-term value. Modern climate control systems integrate better with glass structures due to consistent thermal properties. Automation systems perform more predictably in glass environments, increasing facility attractiveness to sophisticated buyers.

Regional market preferences influence resale potential. European buyers strongly prefer glass installations for high-value crop production. Southeast Asian markets accept polycarbonate systems for most applications. Understanding local preferences helps optimize initial material selection.

| Financial Factor | Glass (20-year analysis) | Polycarbonate (20-year analysis) | CFGET ROI Data |

|---|---|---|---|

| Initial investment | $55-75/m² | $35-45/m² | Installation costs |

| Annual energy costs | $8-12/m² | $6-9/m² | Climate-dependent |

| Maintenance expenses | $1-2/m² | $2-4/m² | Regional averages |

| Replacement costs | $0 (years 1-20) | $20-25/m² (year 15) | Material lifespan |

| Resale value (20 years) | 60-70% | 30-40% | Market analysis |

| Total cost of ownership | $85-115/m² | $80-110/m² | Complete lifecycle |

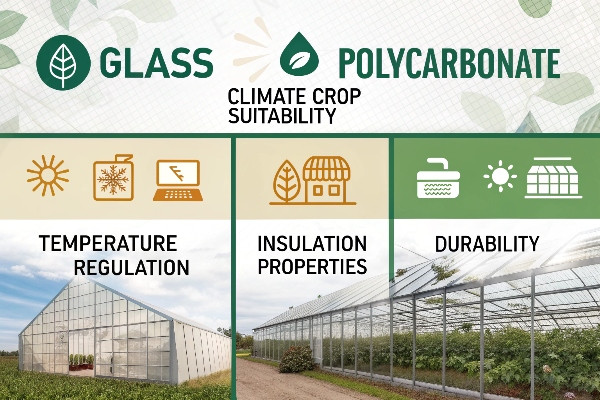

Climate & Crop Suitability: Which Material Combinations Deliver Maximum Productivity in Your Specific Growing Environment?

Successful greenhouse operations require precise matching of covering materials to crop requirements and local climate conditions. Generic recommendations ignore critical interactions between plant physiology, environmental control, and material properties.

CFGET’s global project database shows that climate-crop-material matching determines 60-70% of operational success. Wrong combinations can reduce yields by 25-30% regardless of other system quality.

Precision Agriculture Material Requirements

High-value crop production demands consistent environmental conditions and maximum light quality. Our European research facility installations exclusively use glass for experimental work. Scientists require repeatable conditions impossible with material variables affecting results.

Cut flower operations present specific material requirements. Dutch flower auctions grade products partially on color intensity and consistency. Glass installations produce flowers with 10-15% better color ratings compared to polycarbonate facilities. This quality difference can increase product values by 20-30% in premium markets.

Pharmaceutical crop production requires validated growing conditions. Glass provides the most predictable and measurable growing environment. Our medicinal herb installations use glass specifically for regulatory compliance and product consistency requirements.

Seed production facilities need maximum genetic expression and uniformity. Glass installations deliver the environmental precision required for parent line maintenance and hybrid seed production. Polycarbonate’s light diffusion can mask genetic variations important for breeding programs.

Volume Production Optimization

Large-scale vegetable production prioritizes cost efficiency and operational simplicity. Our Southeast Asian installations focus on high-volume, low-margin crops like leafy greens and herbs. Polycarbonate systems provide adequate growing conditions at much lower investment levels.

Tomato production economics vary by market positioning. Premium tomato operations use glass for maximum fruit quality and extended growing seasons. Processing tomato operations often choose polycarbonate for cost efficiency while maintaining acceptable quality levels.

Nursery operations require different material considerations. Young plants need protection from environmental extremes more than maximum light levels. Polycarbonate’s insulating properties create more stable conditions for plant propagation and early development stages.

Ornamental plant production depends on visual quality standards. High-end landscaping plants require glass for color development and compact growth habits. Mass market ornamentals perform adequately under polycarbonate while benefiting from lower production costs.

Regional Adaptation Strategies

Middle Eastern installations face extreme heat and intense solar radiation. Glass installations require sophisticated cooling systems but provide excellent sand and wind resistance. Our UAE projects use specialized glass with low-iron content for maximum light transmission combined with extensive evaporative cooling systems.

Polycarbonate installations in desert climates need UV-resistant coatings and careful thermal management. The material’s insulating properties can create overheating problems without proper ventilation design. Our Saudi installations use double-wall polycarbonate with automated ventilation for temperature control.

Tropical installations deal with high humidity and storm exposure. Glass performs well in dry tropical climates but suffers from condensation problems in humid conditions. Our Thai installations use glass with automated condensation management systems for high-value crops.

Polycarbonate excels in humid tropical conditions due to better condensation handling and storm resistance. Our Indonesian installations predominantly use polycarbonate for both cost efficiency and climate adaptation. The material’s flexibility handles thermal expansion better in high-temperature, high-humidity environments.

Continental climate installations experience extreme seasonal variations. Glass maximizes winter light penetration crucial for year-round production. Our Eastern European installations use high-transmission glass with extensive insulation systems for energy efficiency.

Polycarbonate installations in continental climates focus on thermal stability and impact resistance. Hail storms and extreme temperature swings favor polycarbonate’s flexibility and insulating properties. Our Central Asian installations choose polycarbonate specifically for extreme weather resistance.

| Application Type | Recommended Material | Climate Suitability | Yield Impact | CFGET Experience |

|---|---|---|---|---|

| Research/breeding | Glass | All climates | Critical precision | 50+ installations |

| High-value flowers | Glass | Temperate/arid | +15-20% quality | European markets |

| Volume vegetables | Polycarbonate | Tropical/humid | Cost optimization | Southeast Asia |

| Pharmaceutical crops | Glass | Controlled environments | Regulatory compliance | Specialized facilities |

| Nursery propagation | Polycarbonate | Variable conditions | Environmental stability | Global projects |

| Processing crops | Film/Polycarbonate | Cost-sensitive markets | Adequate performance | Developing regions |

Technology Integration Considerations

Modern greenhouse operations integrate sophisticated environmental control systems. Glass installations provide more predictable thermal behavior for automated climate control. Sensors and actuators perform more consistently in glass environments due to stable thermal conditions.

Polycarbonate installations require more sophisticated control algorithms to account for material thermal properties. The insulating effects create temperature stratification requiring multi-zone sensing and control systems.

Energy curtain systems work differently with various covering materials. Glass installations benefit from internal thermal screens for night insulation. Polycarbonate installations may not require thermal screens in moderate climates due to inherent insulating properties.

Automated shading systems integrate better with glass installations. External shade cloth systems protect glass from overheating while maintaining structural integrity. Polycarbonate may not require shading in many applications due to light filtering properties.

Conclusion

Choose greenhouse covering materials based on comprehensive analysis of climate, crops, and operational requirements – not just initial costs. CFGET’s experience proves that proper material matching determines long-term success more than any other single factor.