Commercial greenhouse diversity can overwhelm new growers. Understanding the main categories helps you choose the right structure for your specific needs and climate conditions.

Commercial greenhouses fall into three primary classification systems: by use (nursery, vegetable, floriculture), by structure (single-span, multi-span, special designs), and by covering material (poly film, glass, polycarbonate). Each category serves different crop requirements, climate conditions, and budget considerations.

During my 29 years in greenhouse manufacturing, I’ve witnessed the evolution from simple structures to sophisticated growing environments. The diversity of commercial greenhouses reflects the unique needs of different crops, climates, and growing operations. Each type serves specific purposes and offers distinct advantages depending on your agricultural goals.

Don’t Miss:——Commercial Greenhouse Materials Showdown: Polycarbonate vs Glass – Which Covering Will Maximize Your 2025 ROI?

You might like:——What is a Smart Greenhouse? The Ultimate Guide to Automated Growing

By Use: Nursery, Vegetable, Floriculture Greenhouses?

Different crops demand specialized growing environments. Nursery, vegetable, and floriculture operations each require unique structural features and environmental controls.

Nursery greenhouses prioritize flexibility and mobility with bench systems and optimal air circulation. Vegetable greenhouses focus on maximizing growing space with vertical support systems. Floriculture greenhouses emphasize precise climate control and aesthetic presentation for premium flower production.

Nursery greenhouses serve as plant production facilities where young plants develop before transplanting to final locations. These structures typically feature moveable bench systems that allow flexible space utilization. The design prioritizes excellent air circulation to prevent fungal diseases common in high-density seedling environments. Roof vents and side ventilation systems work together to maintain optimal airflow patterns.

Height requirements for nursery greenhouses remain moderate, typically 3-4 meters to the gutter. This allows efficient heating and cooling while providing adequate space for plant growth. The focus stays on creating uniform growing conditions across large numbers of small plants rather than accommodating tall mature crops.

Vegetable greenhouses maximize production space and support systems for climbing crops like tomatoes, cucumbers, and peppers. These structures often reach 4-6 meters in height to accommodate vertical growing systems. Truss systems and support wires create frameworks for plants to climb, optimizing light exposure and air circulation around developing fruits.

The design emphasizes efficient workflow patterns for harvesting and maintenance activities. Wide walkways, proper drainage systems, and strategic placement of utility connections support daily operations. Climate control systems focus on maintaining optimal growing conditions for extended harvest periods.

| Greenhouse Type | Typical Height | Key Features | Primary Crops |

|---|---|---|---|

| Nursery | 3-4 meters | Moveable benches, high air circulation | Seedlings, young plants |

| Vegetable | 4-6 meters | Vertical support systems, wide walkways | Tomatoes, cucumbers, peppers |

| Floriculture | 3-5 meters | Precise climate control, aesthetic design | Cut flowers, potted plants |

Floriculture greenhouses combine production efficiency with aesthetic appeal. These facilities often serve dual purposes as growing spaces and display areas for customers. The design incorporates precise climate control systems that maintain optimal conditions for flower development and post-harvest quality.

Temperature and humidity control systems operate with greater precision than other greenhouse types. Flowers require specific environmental conditions during different growth phases, and small variations can significantly impact bloom quality and timing. Advanced control systems monitor and adjust multiple environmental parameters continuously.

Lighting considerations become critical for floriculture operations. Natural light supplementation systems extend growing seasons and improve flower quality. The structural design accommodates both growing lights and display lighting systems that showcase products effectively.

By Structure: Single-Span, Multi-Span, Special Structure Greenhouses?

Structural design determines a greenhouse’s functionality, cost, and suitability for different applications. Single-span, multi-span, and special structures each offer unique advantages for specific situations.

Single-span greenhouses provide independent climate zones and easier construction but higher per-square-meter costs. Multi-span structures offer economies of scale and efficient space utilization with shared walls and systems. Special structures accommodate unique site conditions and specific crop requirements through customized designs.

Single-span greenhouses function as independent growing units with their own structural framework and environmental systems. Each span typically measures 6-12 meters in width, creating manageable growing zones that can operate independently. This design allows different crops or growing conditions within the same facility.

The structural simplicity of single-span designs makes them easier to construct and maintain. Each unit has its own foundation, frame, and covering system, reducing complexity during installation. Repairs and modifications affect only individual spans rather than entire facilities, minimizing operational disruptions.

Cost considerations favor single-span structures for smaller operations or specialized applications. While the per-square-meter cost remains higher than multi-span alternatives, the total investment stays manageable for beginning growers or niche markets. The modular nature allows gradual expansion as operations grow.

Multi-span greenhouses connect multiple growing areas under continuous roof systems. Shared walls and structural elements reduce material costs and improve space efficiency. These structures typically span 20-50 meters in width, creating large uninterrupted growing areas that support mechanized operations.

| Structure Type | Typical Width | Cost Efficiency | Best Applications |

|---|---|---|---|

| Single-Span | 6-12 meters | Lower total cost | Small operations, specialized crops |

| Multi-Span | 20-50 meters | Higher efficiency | Large commercial operations |

| Special Structure | Variable | Customized | Unique site conditions |

Environmental control systems operate more efficiently in multi-span structures. Shared heating, cooling, and ventilation systems reduce equipment costs and energy consumption per square meter. The larger air volume creates more stable growing conditions with less temperature fluctuation.

Construction efficiency improves significantly with multi-span designs. Shared foundations, fewer exterior walls, and streamlined utility installations reduce labor costs and construction time. The economies of scale become more pronounced as facility size increases.

Special structure greenhouses address unique site conditions or specific crop requirements that standard designs cannot accommodate. These custom solutions might include curved roofs for wind resistance, asymmetrical designs for sloped sites, or integrated storage and processing areas.

Flat-roof greenhouses represent one special structure category that suits urban environments or facilities requiring rooftop installations. These designs integrate with existing buildings or provide platforms for additional equipment installations. The structural engineering accommodates different load requirements and architectural constraints.

Large-span greenhouses eliminate interior support columns to accommodate mechanized equipment or specific crop layouts. These structures require advanced engineering to support roof loads across extended distances without intermediate supports. The design complexity increases costs but provides operational advantages for certain applications.

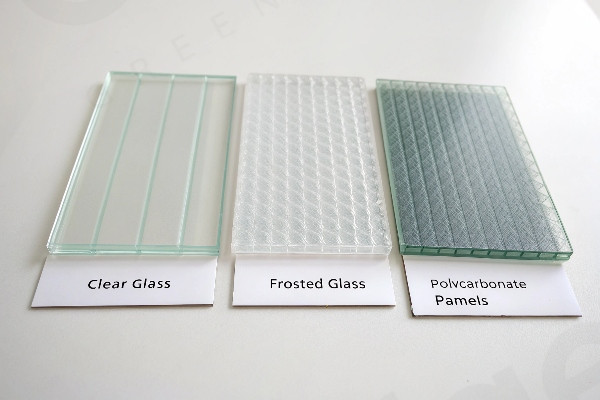

By Covering Material: Poly Film, Glass, Polycarbonate Greenhouses?

Covering materials significantly impact greenhouse performance, durability, and cost. Poly film, glass, and polycarbonate each offer distinct advantages for different applications and budgets.

Poly film greenhouses provide the lowest initial cost and good light transmission but require frequent replacement every 3-4 years. Glass greenhouses offer superior durability and light quality with higher initial investment. Polycarbonate greenhouses balance cost, insulation, and durability for optimal long-term value.

Poly film1 greenhouses dominate the commercial market due to their affordability and versatility. Modern greenhouse films provide excellent light transmission, typically 85-90% for new installations. The material flexibility allows complex roof shapes and easy installation over various structural designs.

Cost advantages make poly film attractive for large-scale operations and beginning growers. Material costs range from $2-4 per square meter, significantly lower than glass or polycarbonate alternatives. Installation requires minimal specialized equipment, reducing labor costs and construction complexity.

Durability limitations require regular replacement cycles. Standard greenhouse films last 3-4 years under normal conditions, with degradation accelerating in high-UV environments. Replacement costs and operational disruptions must factor into long-term financial planning.

Glass greenhouses2 provide superior light transmission and virtually unlimited lifespan when properly maintained. The material allows 90-95% light transmission and maintains clarity over decades of use. Glass creates premium growing environments that justify higher initial investments for high-value crops.

| Covering Material | Light Transmission | Lifespan | Cost ($/m²) | Insulation Value |

|---|---|---|---|---|

| Poly Film | 85-90% | 3-4 years | $2-4 | Low |

| Glass | 90-95% | 20+ years | $15-25 | Low |

| Polycarbonate | 80-85% | 10-15 years | $8-15 | High |

You might like:——An Introduction to Polycarbonate Greenhouses: What You Need to Know?

Structural requirements increase significantly for glass installations. The material weight demands stronger frameworks and foundations, increasing construction costs beyond the covering material itself. Wind and snow load calculations become more critical due to glass brittleness and weight distribution.

Maintenance considerations favor glass for long-term operations. The material resists scratching, chemical damage, and UV degradation that affect other covering options. Cleaning systems maintain optimal light transmission throughout the facility’s lifespan.

Polycarbonate greenhouses offer balanced performance across multiple criteria. The material provides good light transmission while offering superior insulation properties compared to single-layer alternatives. Twin-wall and multi-wall configurations trap air for enhanced thermal performance.

Durability characteristics position polycarbonate between poly film and glass options. The material typically lasts 10-15 years with proper maintenance, providing better long-term value than poly film while avoiding glass’s high initial costs and structural requirements.

Impact resistance makes polycarbonate suitable for challenging environments. The material withstands hail, wind-blown debris, and thermal stress better than glass while maintaining structural integrity. This durability reduces insurance costs and operational risks in severe weather regions.

What Are Common High-Tech Greenhouses?

High-tech greenhouses3 integrate advanced systems for precise environmental control and automated operations. These facilities represent the cutting edge of controlled environment agriculture.

Common high-tech greenhouses include climate-controlled facilities with automated systems, hydroponic growing environments, and integrated pest management systems. Features include computerized climate control, automated irrigation, CO2 supplementation, and real-time monitoring systems that optimize growing conditions continuously.

Climate-controlled greenhouses utilize sophisticated environmental management systems that monitor and adjust temperature, humidity, light levels, and air circulation automatically. These systems respond to both internal conditions and external weather patterns to maintain optimal growing environments regardless of outside conditions.

Sensor networks throughout the facility collect data on multiple environmental parameters every few minutes. Temperature sensors at different heights, humidity monitors, light meters, and CO2 analyzers provide comprehensive environmental data. This information feeds into central control systems that make automatic adjustments to heating, cooling, ventilation, and other systems.

Automated irrigation systems deliver precise amounts of water and nutrients to individual plants or growing zones. These systems can adjust delivery schedules based on plant growth stages, environmental conditions, and soil moisture levels. Fertigation systems combine irrigation with nutrient delivery for optimal plant nutrition.

Hydroponic growing systems eliminate soil-based growing in favor of nutrient solutions delivered directly to plant roots. These systems provide precise control over plant nutrition while reducing water consumption and eliminating soil-borne diseases. Various hydroponic methods include nutrient film technique (NFT), deep water culture, and media-based systems.

| High-Tech Feature | Benefits | Typical Cost Increase |

|---|---|---|

| Climate Control Systems | Precise environmental control | 20-30% |

| Automated Irrigation | Water and labor savings | 15-25% |

| Hydroponic Systems | Higher yields, disease control | 25-40% |

| Integrated Pest Management | Reduced pesticide use | 10-20% |

Energy management systems optimize heating, cooling, and lighting operations to minimize costs while maintaining optimal growing conditions. These systems can integrate with renewable energy sources, thermal storage systems, and grid management programs to reduce operational expenses.

Advanced lighting systems supplement natural light with LED fixtures that provide specific light spectrums for different crops and growth stages. These systems can adjust light intensity, duration, and spectrum automatically based on natural light conditions and plant requirements.

Integrated pest management (IPM) systems combine biological controls, environmental monitoring, and targeted treatments to manage pest populations without excessive pesticide use. These systems include beneficial insect releases, pheromone traps, and automated monitoring systems that detect pest problems early.

Data collection and analysis systems track plant growth, environmental conditions, and operational metrics to optimize performance continuously. These systems can predict optimal harvest timing, identify potential problems before they become serious, and provide detailed production records for quality control and traceability.

Structural innovations in high-tech greenhouses include retractable roof systems that provide natural ventilation and rain protection, moveable growing systems that optimize space utilization, and integrated processing areas that streamline post-harvest operations.

Conclusion

Commercial greenhouses encompass diverse types serving different crops, structures, and covering materials, with high-tech systems offering advanced automation and precision control for optimal growing conditions.

-

Explore this link to understand the benefits and limitations of poly film greenhouses, helping you make informed decisions for your agricultural needs. ↩

-

Discover the advantages of glass greenhouses, including durability and light quality, which can enhance your crop production and investment. ↩

-

Learn about the cutting-edge technologies in high-tech greenhouses that optimize growing conditions and increase efficiency in agriculture. ↩