Are you struggling to choose between light deprivation greenhouses and indoor farms? Many growers face massive losses from wrong decisions.

After 29 years at CFGET, I’ve seen both systems transform agriculture. Light dep greenhouses blend natural sunlight with controlled darkness, while indoor farms offer complete environmental control. Your choice impacts initial costs, operating expenses, crop yields, and long-term profitability.

The agricultural industry stands at a crossroads in 2025. Traditional farming methods no longer meet the demands of our growing population and changing climate. At CFGET, we’ve helped over 500 clients across Southeast Asia, Europe, America, and Central Asia make this critical choice. The decision between light deprivation greenhouses and indoor farming systems can determine your operation’s success for decades.

Don’t Miss:——Commercial Hydroponic Greenhouse Systems: How Do Design, Construction, and ROI Interconnect?

You might like:——What is a Smart Greenhouse? The Ultimate Guide to Automated Growing

How Light Dep Greenhouses Work and Rely on Natural Light?

Picture this: you’re growing premium cannabis in Thailand’s tropical climate. Sudden light changes ruin your flowering schedule and cost thousands in lost revenue.

Light deprivation greenhouses use automated blackout systems to control photoperiods while maximizing natural sunlight. They create artificial seasons, triggering plant flowering cycles regardless of outdoor conditions.

Light deprivation technology revolutionizes how we approach photosensitive crop cultivation. The system works by combining natural sunlight during designated periods with complete darkness through automated blackout curtains or retractable covers. This approach allows growers to manipulate plant flowering cycles artificially, creating multiple harvest seasons per year.

The core mechanism relies on photoperiodism – how plants respond to light and dark periods. Cannabis, for example, requires 12 hours of uninterrupted darkness to trigger flowering. Our light dep systems at CFGET use precision timers and blackout materials that achieve 99.9% light exclusion. The curtains deploy automatically, ensuring consistent dark periods regardless of external conditions.

Key Components of Light Dep Systems

| Component | Function | Benefit |

|---|---|---|

| Blackout Curtains | Block external light | Precise photoperiod control |

| Automated Motors | Deploy/retract covers | Consistent timing |

| Light Sensors | Monitor ambient conditions | Optimal light management |

| Ventilation Systems | Maintain air circulation | Prevent heat buildup |

| Backup Power | Ensure system reliability | Protect crop cycles |

Natural light utilization remains the greatest advantage of light dep greenhouses. Plants receive full-spectrum sunlight during growing hours, promoting robust photosynthesis and natural plant development. This approach reduces energy costs significantly compared to fully artificial lighting systems. The quality of natural sunlight cannot be replicated by any artificial source, resulting in superior plant health and often better flavor profiles in crops like tomatoes and herbs.

However, successful light dep operations require careful environmental monitoring. Temperature and humidity can fluctuate dramatically when blackout systems engage, especially in tropical climates. Our clients in Southeast Asia often struggle with heat buildup during dark periods. We’ve developed specialized ventilation systems that maintain optimal conditions without compromising light exclusion.

Fully Controlled Environment Technology and Advantages of Indoor Farming?

Your outdoor crops failed again due to unexpected weather. Pests destroyed half your harvest, and inconsistent quality hurt your premium market reputation.

Indoor farming eliminates weather dependency through complete environmental control. Advanced LED systems, climate control, and hydroponic nutrition deliver consistent harvests year-round with predictable quality and yields.

Indoor farming represents the pinnacle of agricultural control technology. Every environmental factor – light spectrum, intensity, photoperiod, temperature, humidity, CO2 levels, and nutrient delivery – operates under precise management. This level of control enables consistent production regardless of external weather conditions, seasonal variations, or geographic limitations.

The foundation of modern indoor farming rests on LED lighting technology. Today’s horticultural LEDs can produce specific light spectrums tailored to individual crop requirements. Red light promotes flowering and fruiting, blue light encourages vegetative growth, and full-spectrum combinations optimize overall plant health. Energy efficiency has improved dramatically, with modern LEDs producing more photosynthetic photon flux density (PPFD) per watt than ever before.

Climate control systems in indoor farms operate with surgical precision. Temperature variations of less than 1°C are achievable, while humidity control prevents disease issues common in traditional agriculture. CO2 enrichment systems can maintain optimal levels of 800-1200 ppm, significantly boosting photosynthesis rates and plant growth speed.

Indoor Farming Technology Stack

| Technology | Application | Impact |

|---|---|---|

| LED Grow Lights | Photosynthesis driver | 30-50% faster growth |

| HVAC Systems | Climate control | Disease prevention |

| Hydroponic Systems | Nutrient delivery | 90% water savings |

| Automation Software | System management | Labor cost reduction |

| CO2 Injection | Growth acceleration | 20-40% yield increase |

Vertical farming capabilities multiply production capacity per square foot. Multi-level growing systems can achieve 10-15 times the productivity of traditional field agriculture. This approach becomes particularly valuable in urban environments where land costs are prohibitive for conventional farming methods. Our European clients frequently choose indoor systems specifically for their space efficiency and proximity to urban markets.

Water conservation stands out as another significant advantage. Hydroponic and aeroponic systems recirculate nutrients, reducing water consumption by up to 90% compared to soil-based agriculture. This efficiency proves crucial in water-scarce regions like parts of Central Asia, where our clients face strict water usage regulations.

The sterile environment eliminates most pest and disease issues. Without soil-borne pathogens and with controlled access, indoor farms rarely require pesticides or fungicides. This creates opportunities for organic certification and premium market positioning. However, the initial learning curve can be steep, requiring specialized knowledge in hydroponics, plant nutrition, and environmental controls.

Cost Analysis: Initial Investment vs. Long-Term Operating Expenses?

You’ve heard indoor farming costs millions while light dep greenhouses seem affordable. But hidden operating costs often surprise new growers with budget overruns.

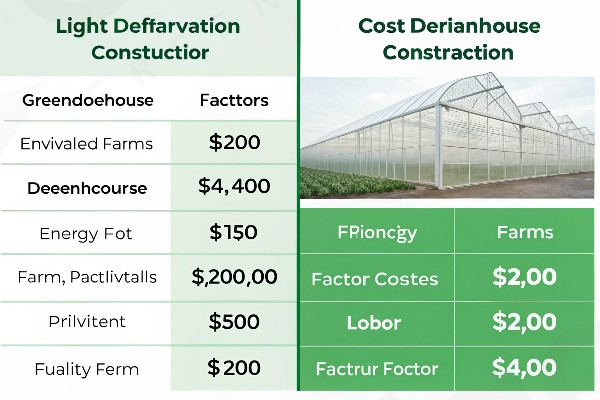

Light dep greenhouses typically cost $15-25 per square foot initially, while indoor farms require $200-400 per square foot. However, energy costs, labor efficiency, and yield potential dramatically affect long-term profitability calculations.

The financial landscape of controlled environment agriculture involves complex calculations beyond simple construction costs. Initial capital expenditure represents only the first consideration in a comprehensive cost analysis. Operating expenses, revenue potential, and return on investment timelines vary significantly between light dep greenhouses and indoor farming systems.

Light deprivation greenhouse construction costs remain relatively modest. Basic structures with automated blackout systems typically range from $15-25 per square foot for quality installations. This includes structural framing, covering materials, blackout curtains, basic environmental controls, and installation. Premium systems with advanced climate control, supplemental lighting, and automation can reach $35-45 per square foot.

Indoor farming facilities require substantially higher initial investments. Warehouse conversions for indoor farming typically cost $200-300 per square foot, while purpose-built facilities can exceed $400 per square foot. These costs include LED lighting systems, HVAC equipment, hydroponic infrastructure, automation systems, and specialized construction requirements like insulation and electrical capacity.

Comparative Cost Analysis

| Cost Category | Light Dep Greenhouse | Indoor Farm |

|---|---|---|

| Initial Construction | $15-45/sq ft | $200-400/sq ft |

| Annual Energy Costs | $2-5/sq ft | $15-25/sq ft |

| Labor Requirements | Medium | Low |

| Maintenance Costs | Low-Medium | Medium-High |

| Insurance Costs | Standard | Premium |

Operating expenses reveal the true cost picture over time. Energy consumption represents the largest ongoing expense difference. Light dep greenhouses primarily use electricity for fans, pumps, and automated systems, resulting in annual energy costs of $2-5 per square foot. Indoor farms require substantial electricity for LED lighting and climate control, typically consuming $15-25 per square foot annually in energy costs alone.

Labor efficiency varies considerably between systems. Indoor farms often achieve higher labor productivity through automation, standardized growing conditions, and year-round production. However, the technical complexity requires skilled operators with specialized knowledge. Light dep greenhouses may require more manual labor for crop management but use readily available agricultural workers.

Maintenance considerations differ significantly. Light dep greenhouses face weather exposure, requiring periodic replacement of covering materials and mechanical components. Indoor facilities protect equipment from weather but require more complex system maintenance, including LED replacements, HVAC servicing, and hydroponic system upkeep.

The revenue equation ultimately determines profitability. Indoor farms typically achieve 3-5 harvest cycles annually compared to 2-3 for light dep greenhouses. Yield per square foot often favors indoor systems, particularly for leafy greens and herbs. However, some crops like tomatoes and cannabis may achieve superior quality under natural sunlight in light dep environments, commanding premium pricing.

Financing options also vary between systems. Light dep greenhouses often qualify for agricultural loans with favorable terms. Indoor farming projects may require commercial or industrial financing at higher rates. Some regions offer renewable energy incentives for LED lighting systems, improving indoor farming economics.

Yield and Quality Insights: Which Method Suits Specific Crops Better?

Your crop selection determines system profitability, but choosing wrong means years of suboptimal returns and market positioning challenges that destroy competitive advantages.

Leafy greens and herbs thrive in indoor farms with 3-4x higher yields, while fruiting crops like tomatoes and cannabis often achieve superior quality and market premiums in light dep greenhouses using natural sunlight.

Crop selection fundamentally influences the success of controlled environment agriculture investments. Different plants respond uniquely to artificial versus natural lighting, controlled versus semi-natural environments, and intensive versus extensive growing methods. Understanding these responses guides optimal system selection for specific production goals and market targets.

Leafy greens represent the ideal indoor farming crops. Lettuce, spinach, kale, and herbs like basil demonstrate exceptional performance under LED lighting. These crops require relatively low light intensity, have short growing cycles, and achieve remarkable productivity in vertical growing systems. Indoor lettuce production can yield 15-20 harvests annually compared to 3-4 outdoor cycles, while maintaining consistent quality and eliminating weather-related crop losses.

The controlled environment eliminates common leafy green challenges like bolting due to temperature fluctuations, pest damage, and seasonal availability issues. Consistent growing conditions produce uniform plant size, color, and texture – critical factors for retail market acceptance. Many of our European clients specifically target premium restaurant markets with their indoor-grown herbs, achieving price premiums of 200-300% over field-grown alternatives.

Crop Performance Comparison

| Crop Category | Indoor Farm Advantage | Light Dep Advantage |

|---|---|---|

| Leafy Greens | 3-4x higher yields | Lower energy costs |

| Herbs | Year-round production | Enhanced flavor profiles |

| Fruiting Vegetables | Consistent quality | Superior taste/aroma |

| Cannabis | Pest-free environment | Higher cannabinoid levels |

| Strawberries | Extended seasons | Natural pollination |

Fruiting crops present more complex considerations. Tomatoes, peppers, cucumbers, and cannabis benefit from natural sunlight’s full spectrum and intensity. While indoor systems can produce these crops successfully, the energy costs for adequate lighting often exceed profit margins. Light dep greenhouses offer an optimal compromise, providing environmental protection while maximizing natural light utilization.

Cannabis cultivation reveals particularly interesting dynamics between systems. Indoor production eliminates weather risks and pest pressures while enabling precise environmental control during critical flowering periods. However, many experienced growers report superior terpene profiles and cannabinoid development under natural sunlight. Light dep greenhouses allow manipulation of flowering triggers while maintaining natural light quality, often resulting in premium-grade products commanding higher market prices.

Quality considerations extend beyond simple yield measurements. Natural sunlight produces complex plant compounds that artificial lighting struggles to replicate. Tomatoes grown under natural light typically exhibit superior flavor profiles, while herbs develop more intense aromatic compounds. This quality difference translates directly into market positioning opportunities and price premiums.

Seasonal production capabilities vary significantly between systems. Indoor farms maintain consistent production year-round, providing supply chain stability and cash flow predictability. Light dep greenhouses in temperate climates may require heating during winter months, increasing operating costs and potentially reducing winter production efficiency.

Market positioning strategies should align with system capabilities. Indoor farms excel at producing consistent, pest-free products for retail chains and food service companies requiring reliable supply. Light dep greenhouse operations often target premium markets, farmers’ markets, and specialty retailers willing to pay premiums for superior flavor and quality.

Regional climate considerations heavily influence crop performance in both systems. Our Southeast Asian clients find indoor farms essential for leafy green production during extreme heat periods, while light dep greenhouses work excellently for year-round fruiting crop production. Central Asian operations often combine both systems, using indoor facilities for high-value crops during harsh winters and light dep greenhouses during favorable seasons.

Conclusion

Choose light dep for premium quality and lower energy costs, or indoor farms for consistent yields and weather independence. Your success depends on matching system capabilities with crop requirements and market demands.