Are you confused about which growing method works best for your crops? Many growers struggle with choosing between light deprivation and indoor systems.

Light deprivation greenhouses use natural sunlight with controlled darkness periods, while indoor farms rely entirely on artificial lighting. Light deprivation costs 40-60% less initially but indoor farms offer year-round consistency regardless of weather conditions.

After 29 years in the greenhouse industry, I have seen countless growers make this crucial decision. The choice between light deprivation and indoor farming affects everything from your initial investment to daily operations. Both systems serve different purposes and excel in specific situations.

Don’t Miss:——Commercial Hydroponic Greenhouse Systems: How Do Design, Construction, and ROI Interconnect?

You might like:——What is a Smart Greenhouse? The Ultimate Guide to Automated Growing

Environmental Control: Who Manages Light, Temperature, and Humidity Better?

Do you need absolute control over every environmental factor? The answer depends on your crop requirements and local climate conditions.

Indoor farms provide complete environmental isolation with precise control over all growing conditions. Light deprivation greenhouses blend natural climate benefits with selective light manipulation, offering 70-80% of indoor control at lower energy costs.

Environmental control represents the core difference between these two systems. In my experience working with clients across Southeast Asia and Europe, indoor farms excel in creating completely artificial growing environments. Every aspect gets controlled through sophisticated systems. Temperature stays within ±1°C of target ranges. Humidity maintains precise levels regardless of outside conditions. Light intensity and spectrum get adjusted hourly if needed.

Indoor farms use multiple sensor networks throughout the growing space. These sensors feed data to central control systems that adjust conditions automatically. The sealed environment eliminates external weather influences completely. This creates ideal conditions for research projects or high-value crops that need exact specifications.

Light deprivation greenhouses work differently. They combine natural environmental benefits with selective control. During daylight hours, natural sunlight provides energy for photosynthesis. The structure still allows some climate interaction with the outside environment. Temperature and humidity partially follow natural patterns, which many crops prefer.

The light deprivation system gives you control over photoperiod timing. Automated curtain systems or blackout covers create darkness when needed. This triggers flowering in light-sensitive plants like cannabis or chrysanthemums. You can manipulate seasons artificially while still using natural light energy.

Climate control in light deprivation systems requires less intensive management. Ventilation systems work with natural air movement. Heating and cooling loads stay lower because the structure uses ambient temperature as a starting point. Humidity control becomes easier in many climates because you work with natural moisture levels rather than fighting them.

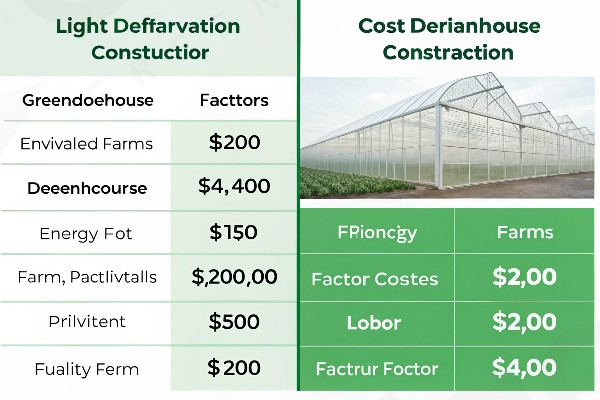

Cost Differences: Which Method Has Higher Initial Investment and Operating Costs?

Are you concerned about the financial commitment required for each system? The cost difference between these technologies can determine project feasibility.

Indoor farms require 3-5 times higher initial investment than light deprivation systems. However, light deprivation greenhouses need 40-50% less energy for lighting while indoor farms offer potentially higher yields per square meter.

The financial aspects of these systems create the biggest decision factor for most growers. Indoor farming facilities demand significant upfront investment. A basic indoor farm costs $4-8 million per acre of growing space. This includes LED lighting systems, HVAC equipment, automation controls, and structural components. The complexity drives costs higher than traditional agriculture.

Light deprivation greenhouses cost $150,000-400,000 per acre depending on automation level and structure quality. The lower cost comes from using natural light as the primary energy source. You still need automated curtain systems, basic climate control, and structural components. But the overall complexity stays much lower than indoor farms.

Operating costs show interesting patterns. Indoor farms consume 30-40 kWh per square foot annually for lighting alone. Add HVAC, automation, and other systems, and energy costs reach $3-6 per square foot per year. In regions with high electricity costs, this becomes a major factor in profitability calculations.

Light deprivation systems use 60-70% less energy overall. Natural light eliminates most lighting costs during daylight hours. Supplemental lighting may be needed during winter months or cloudy periods. Climate control energy needs stay lower because you work with ambient conditions rather than creating artificial ones.

Labor costs differ between systems too. Indoor farms often require specialized technicians for LED maintenance, environmental monitoring, and system troubleshooting. Light deprivation systems need agricultural knowledge but less technical expertise. This affects both hiring costs and ongoing training requirements.

Return on investment timelines vary significantly. Indoor farms typically need 7-12 years to recover initial investment. Light deprivation systems can achieve payback in 3-5 years with proper crop selection and market conditions. The faster payback makes light deprivation more attractive for many commercial growers.

Crop Suitability: Which Technology is Better for My Type of Crops?

Does your crop selection determine which growing method works best? Different plants thrive under different growing conditions and management approaches.

Light deprivation greenhouses excel for photoperiod-sensitive crops like cannabis, hops, and medicinal herbs. Indoor farms work better for leafy greens, microgreens, and year-round production crops that need consistent environmental conditions.

Crop selection drives the choice between these systems more than any other factor. Through my work with growers worldwide, I have learned that certain plants naturally fit better with each approach. The biological needs of your target crops should guide your decision.

Light deprivation systems work exceptionally well for cannabis cultivation. Cannabis plants respond strongly to photoperiod manipulation. Natural sunlight provides excellent growth energy during vegetative stages. When you need to trigger flowering, the blackout system creates the required dark periods. Many growers achieve better terpene profiles and stronger plant structure using natural light1 compared to artificial alternatives.

Hops production also benefits from light deprivation technology. Hops are photoperiod-sensitive plants that need specific day length changes to flower properly. Natural sunlight intensity and spectrum support robust vine growth. The ability to control flowering timing helps coordinate harvests with processing schedules.

Medicinal herb production fits well with light deprivation methods. Many therapeutic compounds develop better under natural light conditions. Plants like echinacea, chamomile, and other medicinal species show improved potency when grown with natural light supplemented by controlled photoperiods.

Indoor farming excels for leafy green production. Lettuce, spinach, kale, and similar crops grow rapidly under controlled LED systems. These plants do not require natural light1 spectrum complexity. They respond well to optimized light recipes that promote fast growth and specific nutritional profiles.

Microgreen production works perfectly in indoor systems. The short growing cycles allow for rapid turnover. Precise environmental control ensures consistent germination and growth rates. You can produce multiple harvests monthly regardless of outside weather conditions.

Strawberry production shows success in both systems but for different reasons. Indoor farms allow year-round production with consistent berry size and quality. Light deprivation greenhouses can extend growing seasons and improve fruit quality through controlled flowering timing.

Tomato and pepper production can work in either system. Indoor farms provide consistent yields but require significant energy input. Light deprivation greenhouses offer good production levels with lower operating costs, especially in moderate climates.

Yield and Quality: Which Method Offers More Consistent or Higher Quality Harvests?

Are you focused on maximizing production quantity or achieving premium quality standards? The yield and quality characteristics differ significantly between these growing methods.

Indoor farms typically produce 10-15 times more yield per square foot annually through vertical growing and year-round production. Light deprivation systems often achieve superior product quality with better flavor profiles and higher concentrations of beneficial compounds.

Yield potential varies dramatically between these systems depending on how you measure productivity. Indoor farms excel in yield per square foot of floor space. Vertical growing systems stack multiple growing levels in the same footprint. A typical indoor farm produces 365 days per year with controlled growing cycles. This combination can generate 10-15 times more annual yield per square foot compared to traditional methods.

Light deprivation greenhouses focus on yield per plant rather than space efficiency. Plants grown under natural light often develop stronger root systems and more robust structure. Individual plant yields frequently exceed those from indoor systems. However, the single-level growing approach limits overall space utilization compared to vertical indoor farms2.

Quality differences become apparent in several ways. Natural light provides a full spectrum that artificial LED systems cannot perfectly replicate. This spectrum complexity affects plant metabolism and compound development. Many growers report better flavor profiles in crops grown under natural light conditions.

Terpene production in cannabis shows marked differences between systems. Light deprivation greenhouse cannabis often exhibits more complex terpene profiles. The natural light spectrum and slight environmental variations seem to stimulate broader compound development. Indoor cannabis can achieve high potency but sometimes lacks the aromatic complexity of greenhouse-grown products.

Nutritional content varies between growing methods too. Studies show that some vegetables grown under natural light contain higher levels of certain vitamins and antioxidants. The stress responses from natural environmental variations may trigger beneficial compound production that controlled indoor conditions cannot replicate.

Consistency represents indoor farming’s strongest advantage. Every harvest meets identical specifications. Plant spacing, growing cycles, and environmental conditions remain constant. This predictability helps with processing, packaging, and distribution planning. Buyers know exactly what to expect from each delivery.

Light deprivation systems show more seasonal variation even with environmental control. Natural light intensity changes throughout the year affect plant development. Some growers view this as a disadvantage, while others appreciate the seasonal quality variations that mirror natural growing patterns.

Harvest timing flexibility differs between systems. Indoor farms can schedule harvests precisely to meet market demands. Growing cycles start and finish on predetermined dates. Light deprivation systems work with natural seasons and photoperiod requirements, which may limit timing flexibility for some crops.

Post-harvest handling requirements also vary. Indoor-grown products often have more delicate structures due to controlled growing conditions. Light deprivation crops typically show better shelf life and transportation durability because they develop under slightly more challenging conditions that strengthen plant tissues.

Conclusion

Choose light deprivation for natural quality and lower costs, or indoor farming for maximum yield consistency and year-round production control.